A new type of internal octagonal bolt frame structure joint and construction method

A frame structure and octagonal technology, which is applied to the joints and construction fields of new-type internal octagonal bolt frame structures, can solve the problems of complex nut installation and reduced bearing capacity, and achieve the effects of reducing danger, improving stability, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

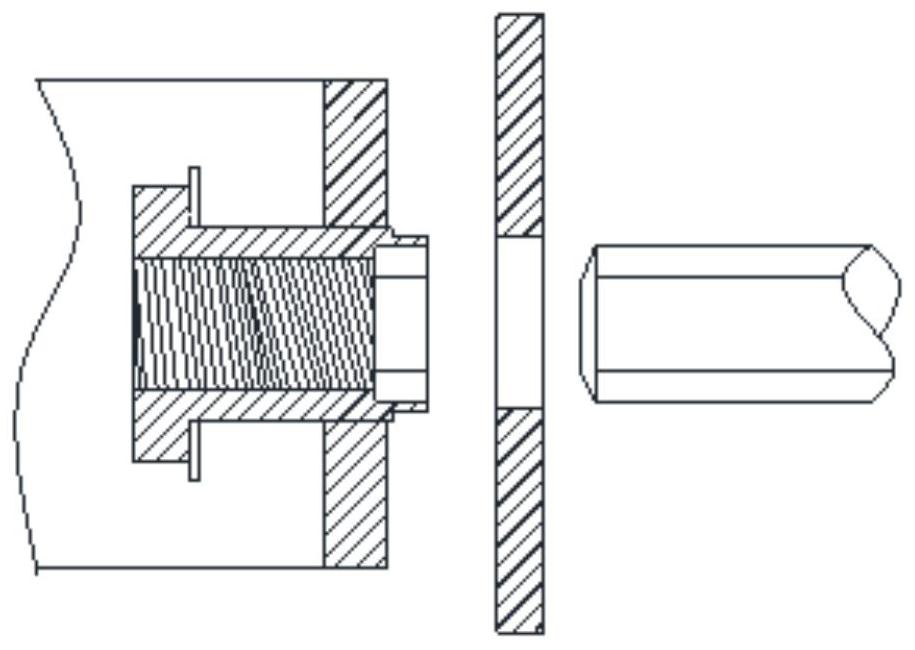

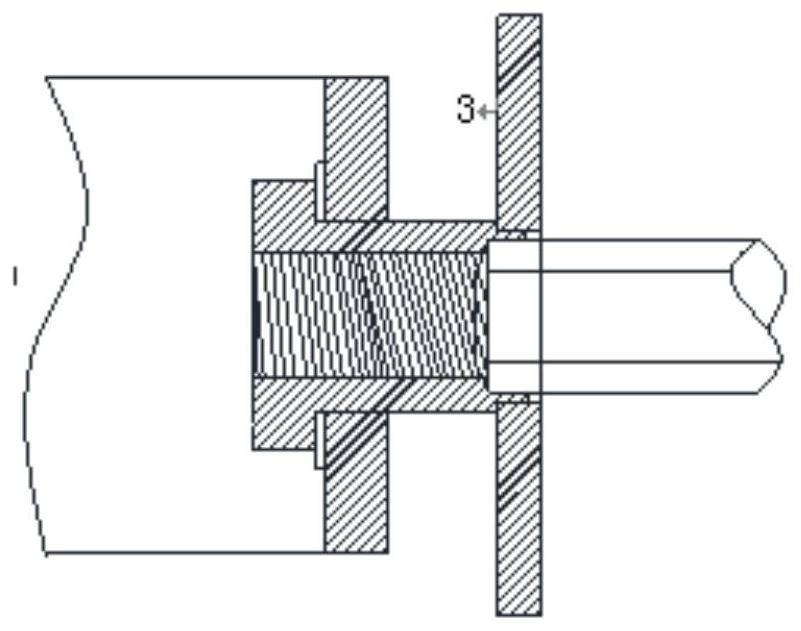

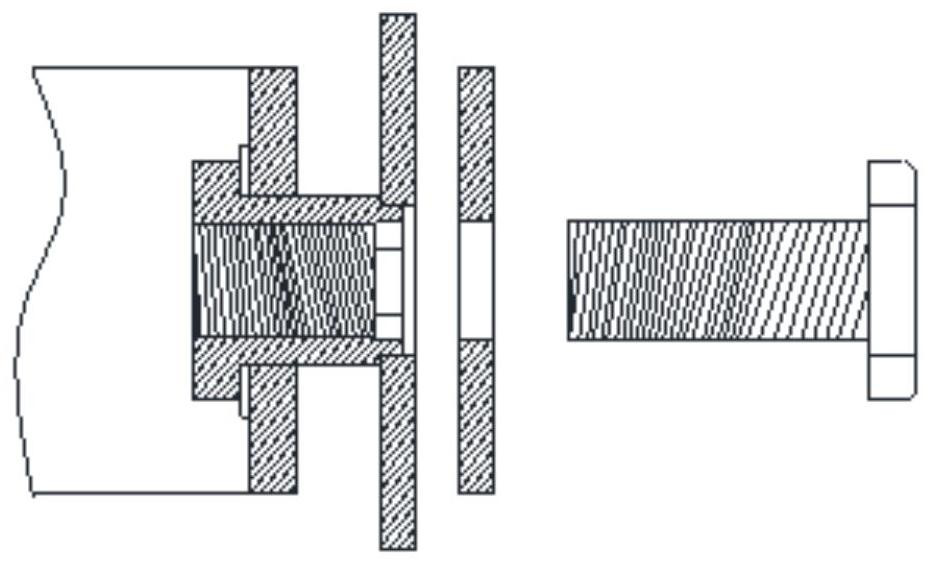

[0027] The schematic diagram of a new type of internal octagonal bolt frame structure node and construction method in this implementation is as follows Figure 1 to Figure 4 As shown, it includes H-shaped steel beam with end plate 1, steel column 2, square steel pipe 3, inner octagonal bolt 4, and bolt sleeve 5.

[0028] refer to Figure 1 to Figure 4 , Figure 6 , Figure 7 As shown, the H-shaped end-plate steel beam 1, steel column 2, and square steel pipe 3 are all prefabricated in the factory. Holes are opened at the corresponding positions of the steel column 2 holes, and the inner walls of the holes are all threaded. After alignment, an internal octagonal wrench is used from the outside to make the bolt sleeve 5 form a temporary partial support inside, and the outside is connected to the H-shaped end plate steel The inner octagonal bolts 4 are place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com