Automatic wire production equipment

A production equipment and wire rod technology, applied in the field of automated production equipment, can solve problems such as inability to adapt, low production efficiency, and low product quality, and achieve the effects of reasonable design, improved production efficiency, and wire rod quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

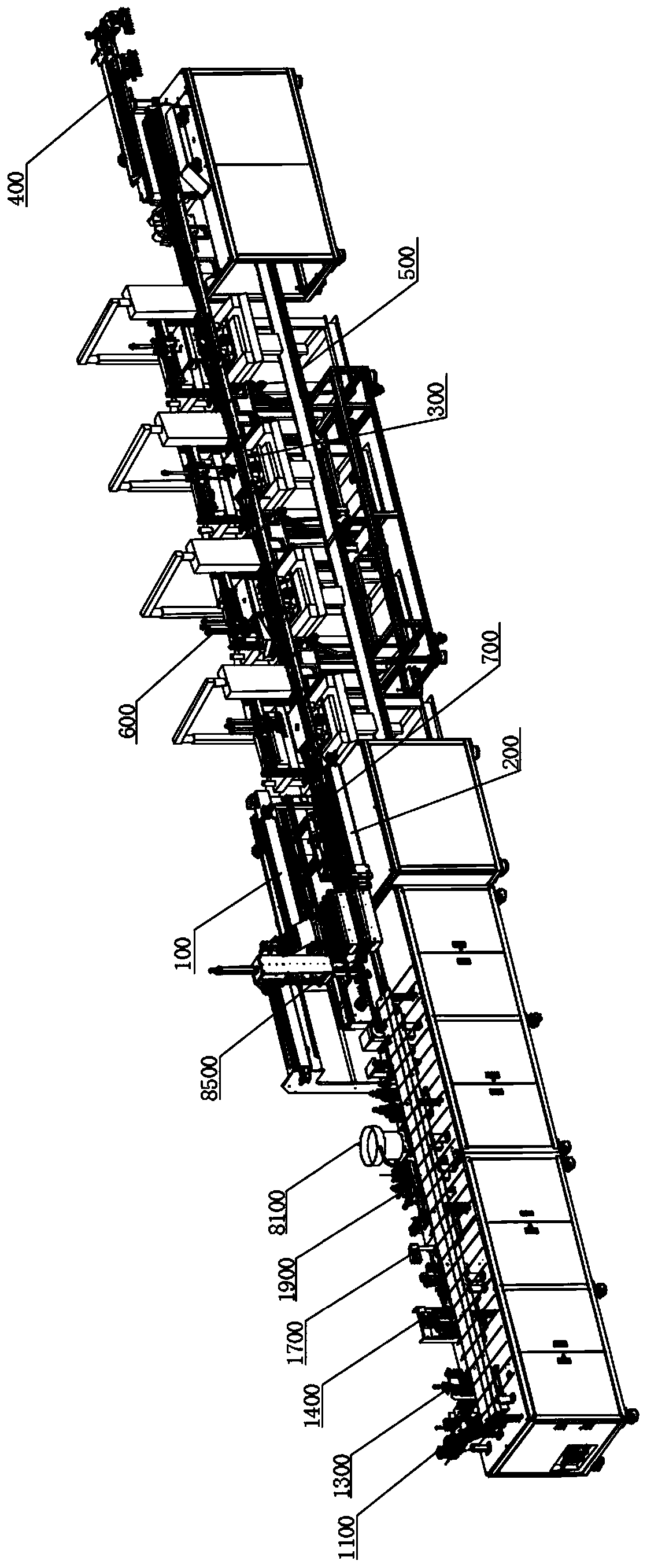

[0074] An automatic production equipment for wire rods, including a wire rod processing front section and a wire rod processing rear section;

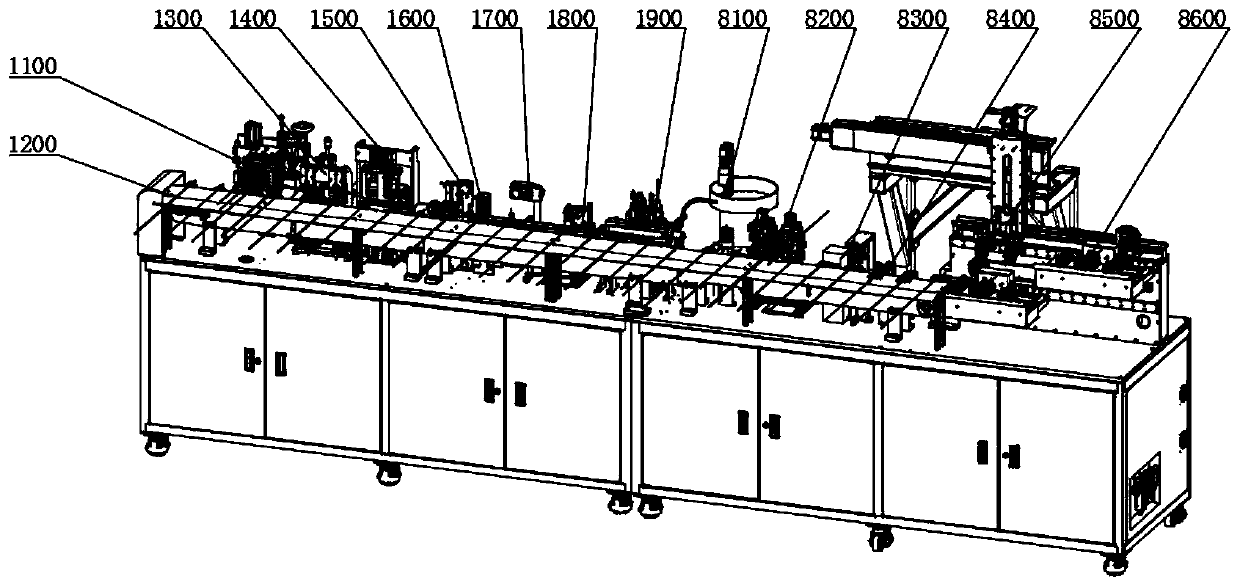

[0075] refer to Figure 1-2 , the front section of the wire processing includes a wire automatic transfer mechanism 1200, a fixed-length cutting mechanism 1100, a peeling mechanism 1300, a core wire stripping mechanism 1400, a twisting mechanism 1500, a wire dividing mechanism 1600, a flux adding device 1700, and a tin immersion mechanism 1800, welding MICRO mechanism 1900, welding detection device 8100, double-head electric measuring mechanism 8200, SR end trimming mechanism 8300, wire taking pre-positioning device 8400, manipulator transfer mechanism 8500, variable distance up and down dislocation connection mechanism 8600.

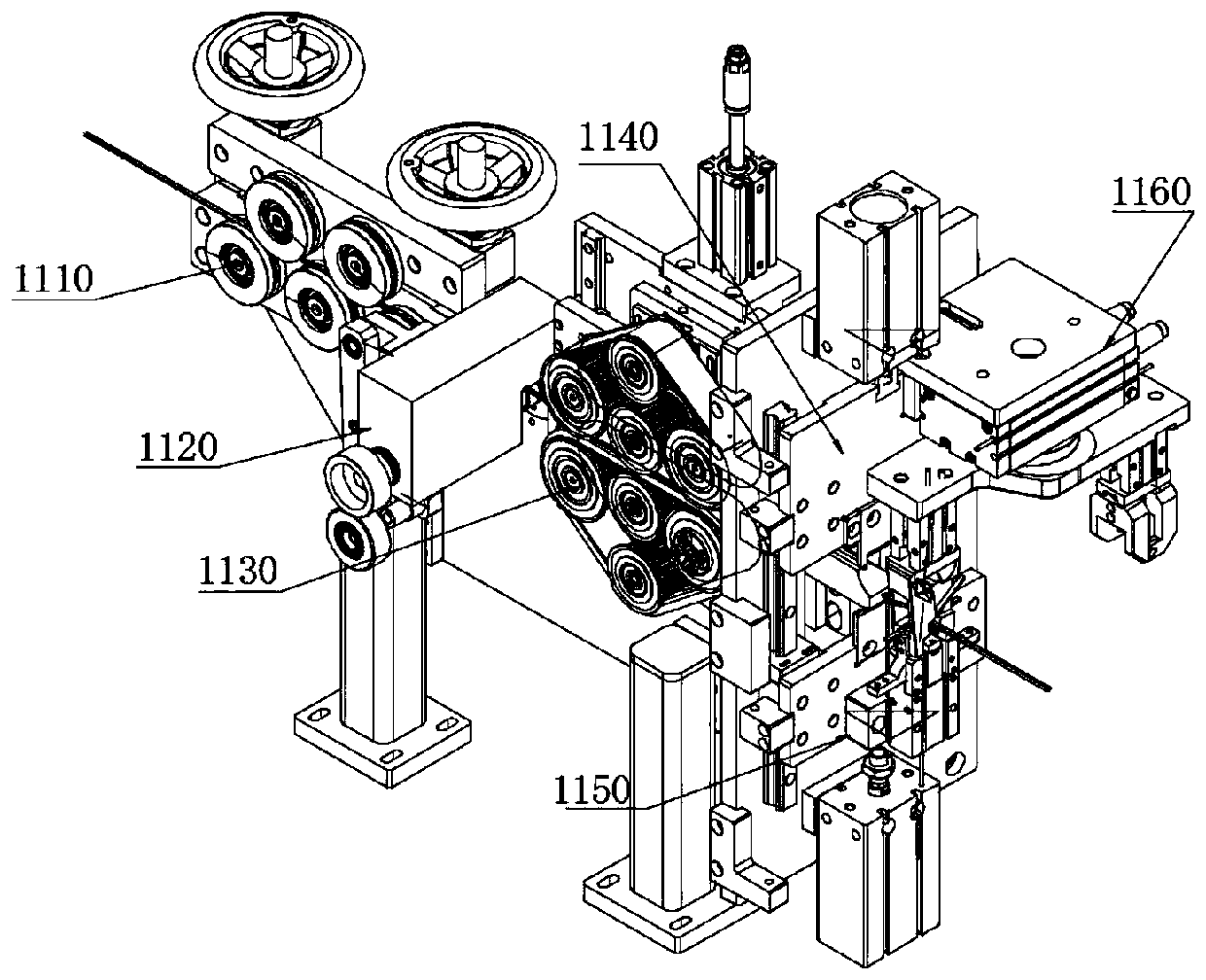

[0076] refer to image 3 The fixed-length cutting mechanism 1100 includes a roller mechanism 1110, an encoder 1120, a synchronous wire feeding mechanism 1130, a first upper cutter 1140, a first lower cutter 115...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com