A wire cutting and anti-stripping device

A wire and anti-scattering technology, which is applied in the field of electric power construction auxiliary equipment, can solve problems such as unfavorable wire cutting, and achieve the effects of improving efficiency and safety, improving efficiency, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

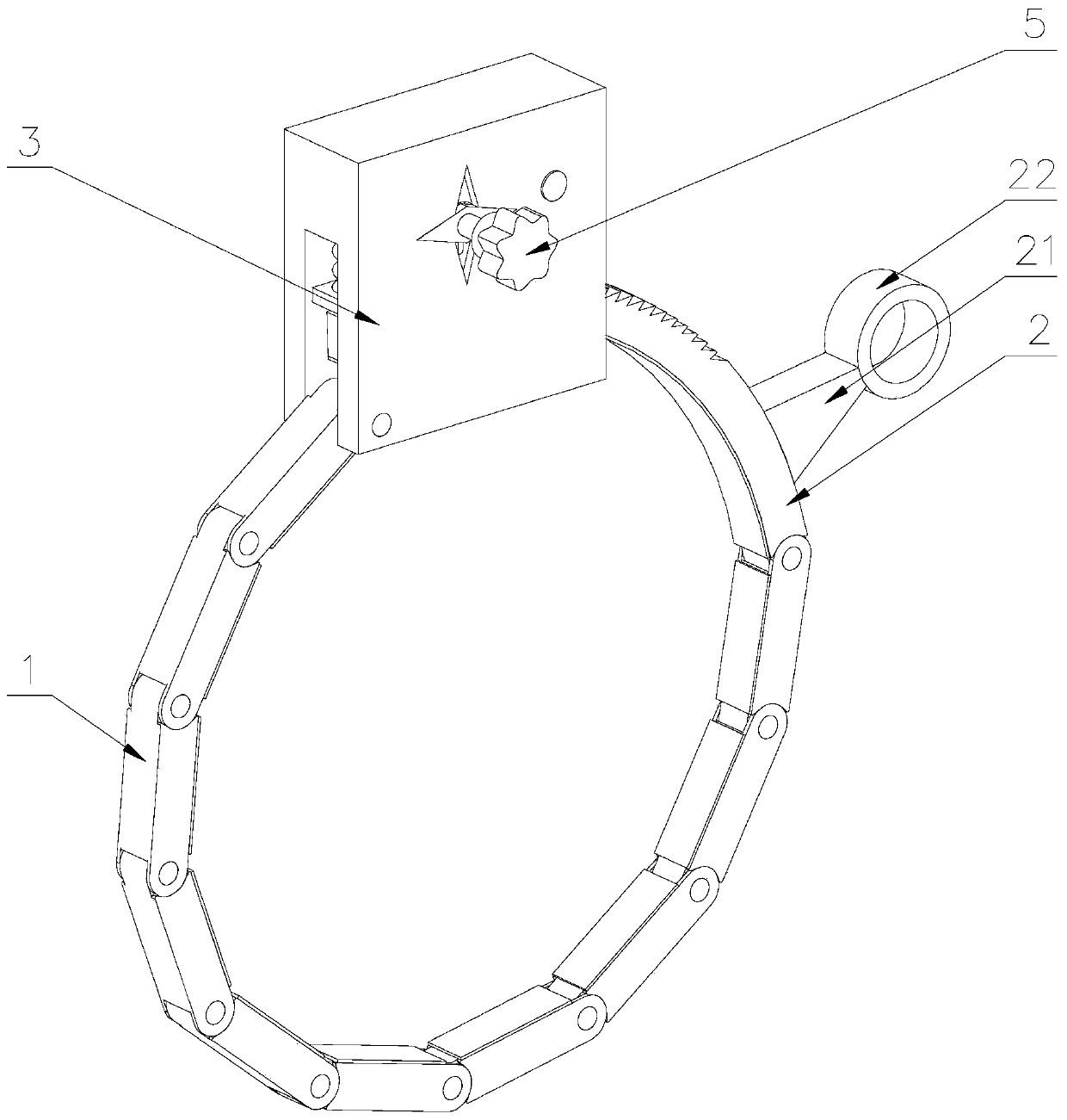

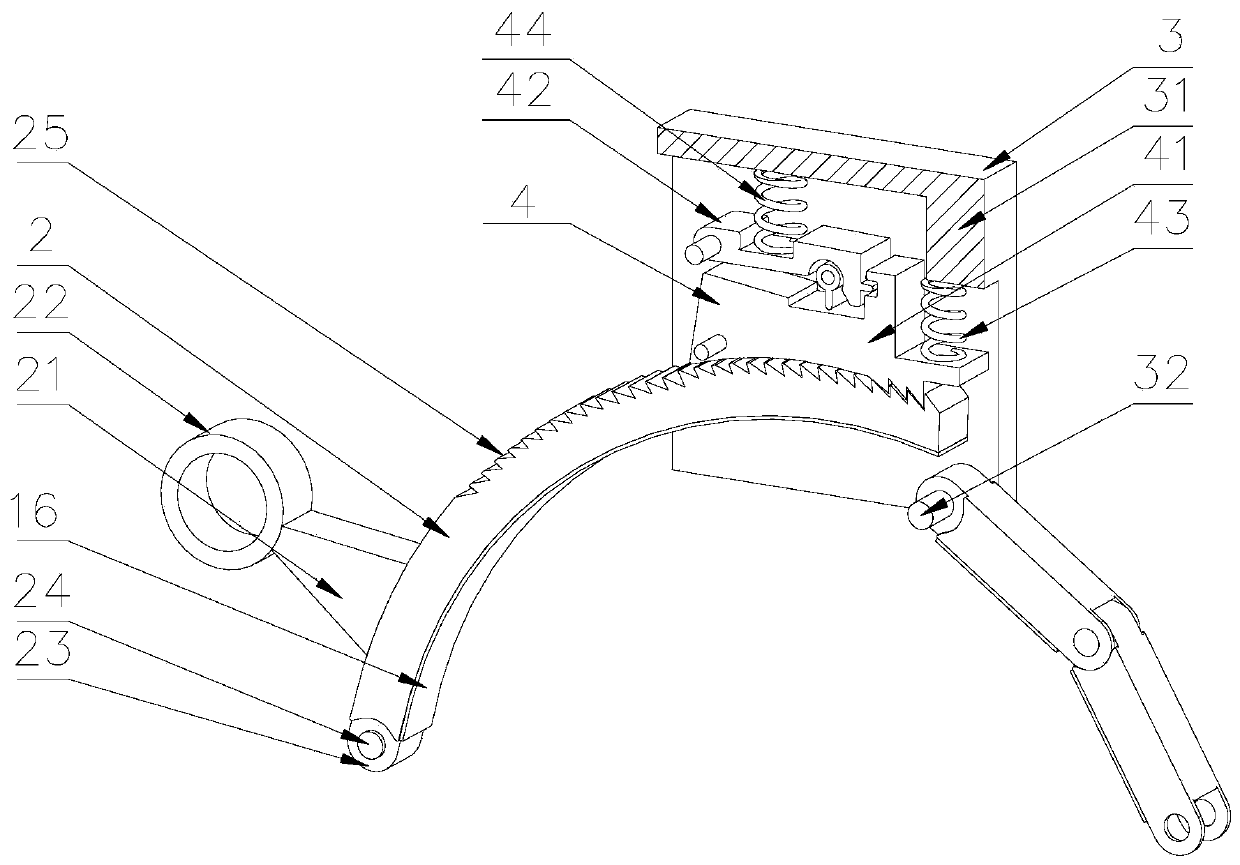

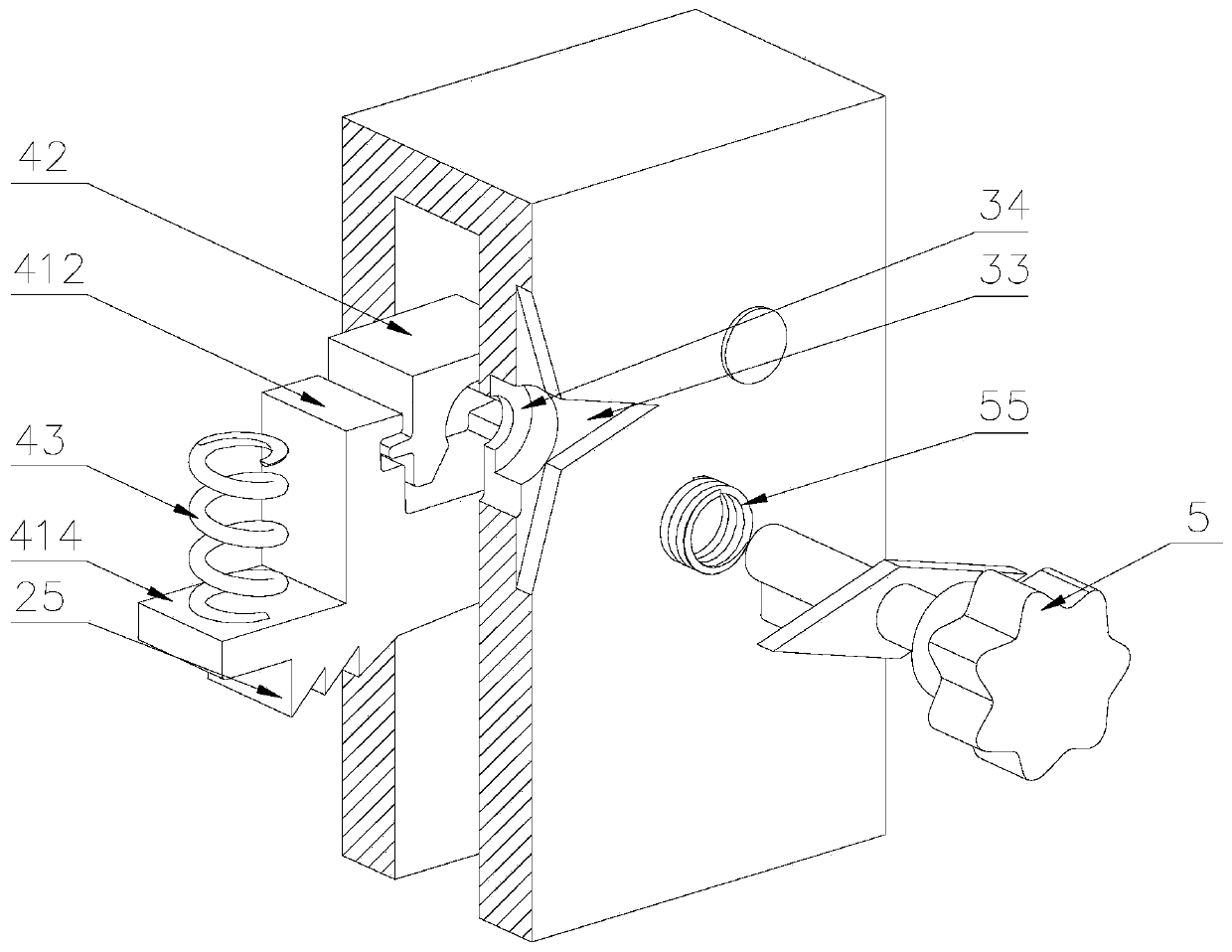

[0047] A wire cutting anti-strand device, including a first connecting arm 1, a second connecting arm 2, a first shield 3, a locking mechanism 4, and an unlocking device 5, the first connecting arm 1 is provided with several groups, the One end of the first connecting arm 1 is provided with a first groove 12, and both sides of the first groove 12 are provided with a clamping plate 11, and a connecting hole 13 is provided on the clamping plate 11; One end is provided with a first hinged joint 14, and first pin shafts 15 are provided on both sides of the first hinged joint 14, and the first pin shafts 15 are movably connected with the connecting holes 13 on the clamping plate 11; multiple sets of first connecting arms 1. The first pin shaft 15 and the connecting hole 13 are sequentially connected to form a flexible connecting arm. When crimping the wire, a circular gap is formed between the first connecting arm 1 and the second connecting arm 2, which increases the gap between th...

Embodiment 2

[0055] The difference from Embodiment 1 is that the locking mechanism 4 includes a rotating shaft 46 and a rocker 48, a second shield 6 is provided on one side of the first shield 3, and one end of the rotating shaft 46 is movably installed on the second On one side of the shield 3, the other end of the rotating shaft 46 is movably installed on one side of the second shield 6; the rotating shaft 46 is fixedly equipped with a second ratchet 47, and the second ratchet 47 is located on the first shield. Inside the cover 3, and the ratchet 25 of the second ratchet 47 is matched with the ratchet 25 of the second connecting arm 2; a first ratchet 45 is provided on one side of the second ratchet 47, and the first ratchet 45 is located on the second Inside the shield 6; the rocking bar 48 is positioned at one side of the second ratchet 47, and the lower end of the rocking bar 48 is fixedly installed on the rotating shaft 46, and one side of the upper part of the rocking bar 48 is provi...

Embodiment 3

[0059] The difference from Embodiment 1 and Embodiment 2 is that when this wire cutting and anti-strand device is used together to cut the middle section of the wire, in order to ensure that the wire is in a tight state, a connection is provided between the two sets of wire cutting and anti-strand devices. device 7, the connection device 7 includes a stud 71, a through hole is provided on the first connecting rod 22, the stud 71 is located inside the through hole, and a first nut is provided on one side of the first connecting rod 22 72. The other side of the first connecting rod 22 is provided with a second nut 73. According to the needs of the construction site, adjust the distance between the two groups of wire cutting and anti-stripping devices, and make the wires in a tight state, and then pass through the first Nut 72 and the second nut 73 fix the positions of the two groups of wire cutting anti-stripping devices, ensuring that the wires are in a tight state, which not on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com