Quartz sand mining area tailings recovery treatment device

A quartz sand tailings, recycling and processing technology, applied in the field of quartz sand recycling, can solve problems such as harming the atmosphere, unfavorable reuse, occupying land, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

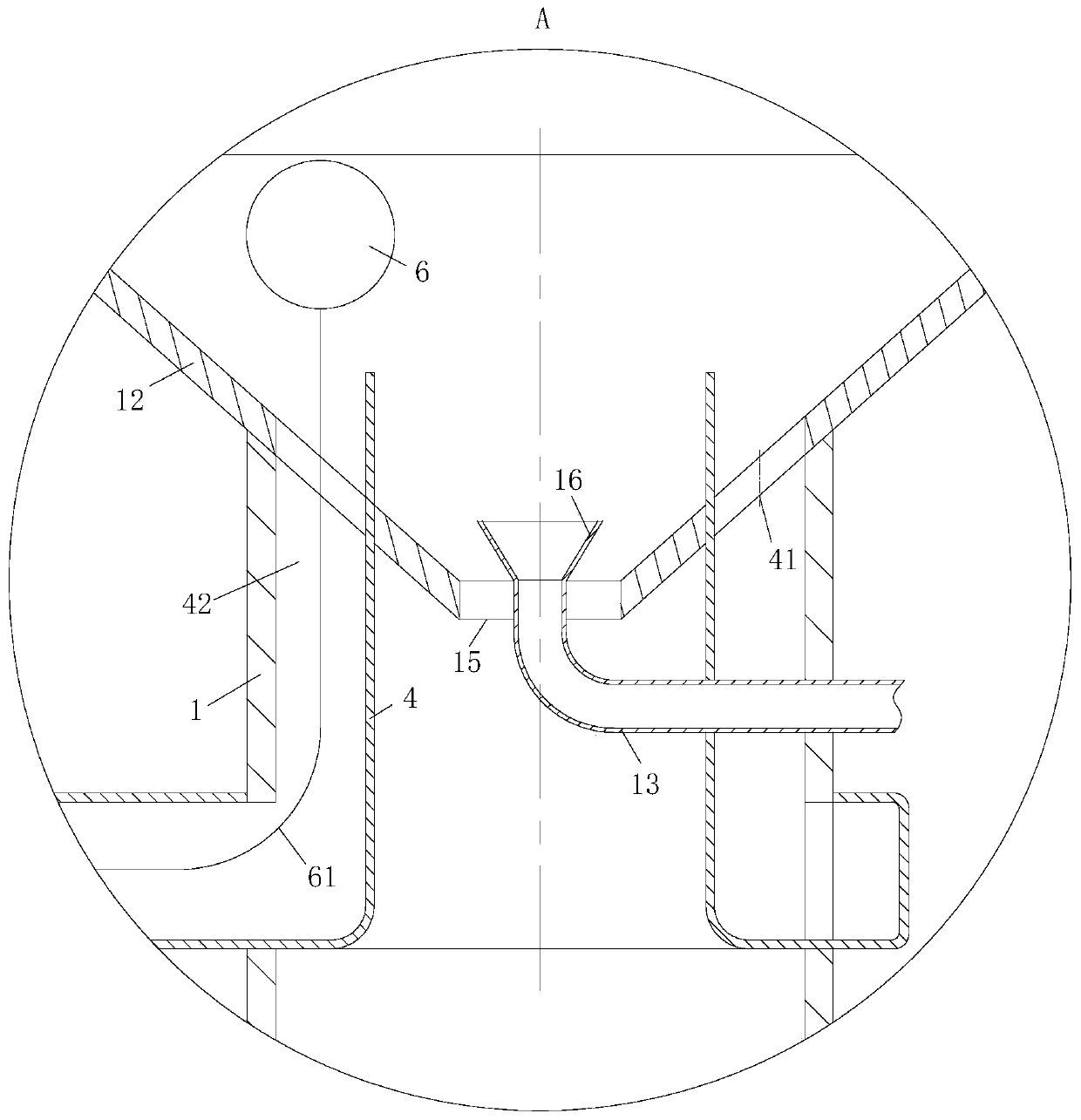

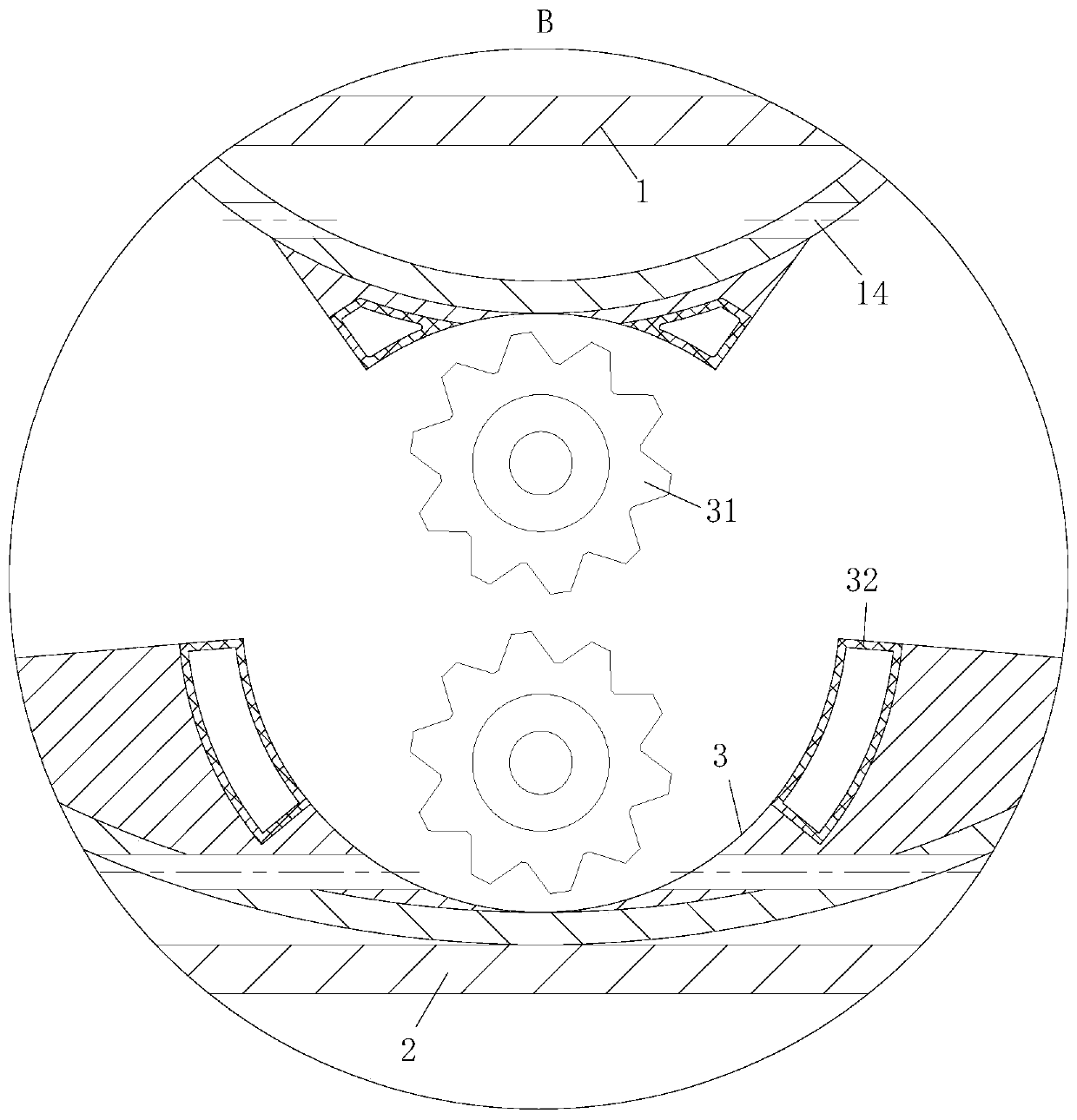

[0024] As an embodiment of the present invention, the U-shaped pipe 1 on the side away from the separation chamber 42 of the connecting pipe 43 is rotatably connected with a water wheel 5, and the agitation of the water wheel 5 can maintain the suspended state of the pulverized quartz sand and iron oxide; The end of the U-shaped tube 1 away from the receiving hopper 12 is connected with a horizontal tube 17, and the horizontal tube 17 is provided with an isolation plate 18; the top of the horizontal tube 17 is provided with a conveyor belt 51, and a group of permanent magnets are uniformly arranged on the conveyor belt 51 52; the driving wheel of the water wheel 5 and the conveyor belt 51 is driven by a belt; through the cooperation between the water wheel 5, the conveyor belt 51, the permanent magnet 52 and the isolation plate 18, the iron oxide in the quartz sand is separated, Further improve the purity of the quartz sand; the quartz sand mixed with iron oxide after the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com