An anatase tio 2 Preparation method of crystal facet heterojunction

An anatase-type, heterojunction technology, applied in chemical instruments and methods, hydrogen production, chemical/physical processes, etc., can solve problems that do not consider anatase-type TiO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

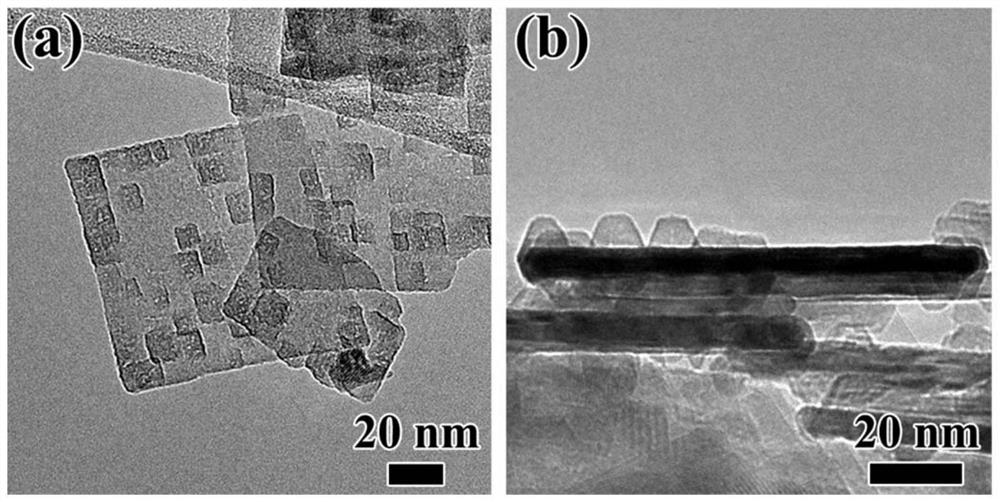

Image

Examples

Embodiment 1

[0027] 1) Measure 300 μL of tetra-n-butyl titanate and inject it into the liner of a reaction kettle containing 25 mL of absolute ethanol, and stir for 10-15 minutes to obtain an organic solution of tetra-n-butyl titanate;

[0028] 2) Under stirring, add 5 mL of ammonia water dropwise to the tetra-n-butyl titanate organic solution prepared in step 1), and stir for 10-20 minutes to obtain a milky white suspension;

[0029] 3) In the stirring state, add 5 mL of deionized water to the milky white suspension obtained in step 2), stir for 10-20 minutes, and the suspension continues to maintain milky white;

[0030] 4) Under stirring, 1 g of anatase TiO with exposed {001} facets 2 Add nanosheets to the milky white suspension obtained in step 3), stir for 2-3 hours, and the suspension will continue to maintain milky white;

[0031] 5) Put the reactor liner equipped with the reaction materials in step 4) into the reactor, seal it, and keep it warm at 200° C. for 12 hours. After the ...

Embodiment 2

[0034] 1) Measure 400 μL of tetra-n-butyl titanate and inject it into the liner of a reaction kettle containing 25 mL of absolute ethanol, and stir for 10-15 minutes to obtain an organic solution of tetra-n-butyl titanate;

[0035] 2) Under stirring, add 5 mL of ammonia water dropwise to the tetra-n-butyl titanate organic solution with different concentrations prepared in step 1), and stir for 10 to 20 minutes to obtain a milky white suspension;

[0036] 3) In the stirring state, add 5 mL of deionized water to the milky white suspension obtained in step 2), stir for 10-20 minutes, and the suspension continues to maintain milky white;

[0037] 4) Under stirring, 1 g of anatase TiO with exposed {001} facets 2 Add nanosheets to the milky white suspension obtained in step 3), stir for 2-3 hours, and the suspension will continue to maintain milky white;

[0038]5) Put the reactor liner equipped with the reaction materials in step 4) into the reactor, seal it, and keep it warm at 2...

Embodiment 3

[0041] 1) Measure 500 μL of tetra-n-butyl titanate and inject it into the liner of a reaction kettle containing 25 mL of absolute ethanol, and stir for 10-15 minutes to obtain an organic solution of tetra-n-butyl titanate;

[0042] 2) Under stirring, add 5 mL of ammonia water dropwise to the tetra-n-butyl titanate organic solution with different concentrations prepared in step 1), and stir for 10 to 20 minutes to obtain a milky white suspension;

[0043] 3) In the stirring state, add 5 mL of deionized water to the milky white suspension obtained in step 2), stir for 10-20 minutes, and the suspension continues to maintain milky white;

[0044] 4) Under stirring, 1 g of anatase TiO with exposed {001} facets 2 Add nanosheets to the milky white suspension obtained in step 3), stir for 2-3 hours, and the suspension will continue to maintain milky white;

[0045] 5) Put the reactor liner equipped with the reaction materials in step 4) into the reactor, seal it, and keep it warm at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com