Crop fertilization equipment with uniform fertilization effect

A crop and uniform technology, applied in the field of crop fertilization equipment, can solve the problems of insufficient contact between soil and fertilizer, uneven fertilization, etc., to achieve the effect of improving fertilization effect, solving uneven fertilization, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

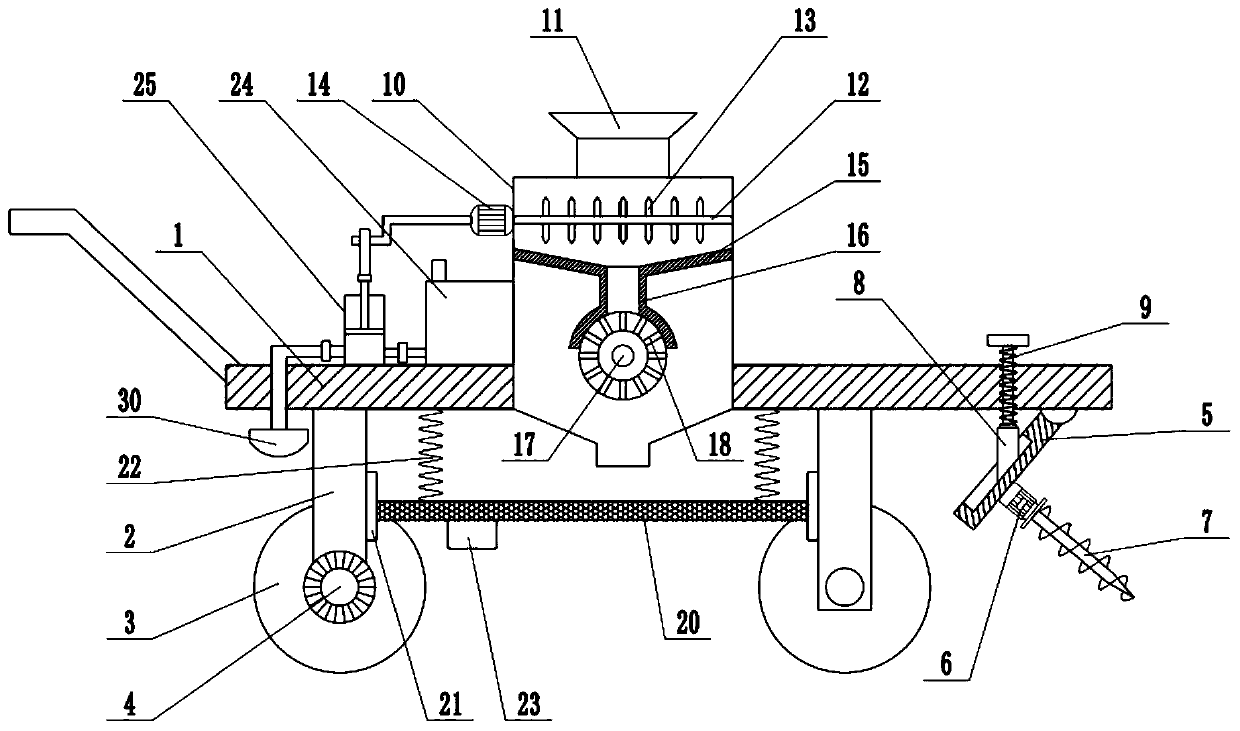

Embodiment 1

[0021] see Figure 1-3 , in the embodiment of the present invention, a kind of crop fertilization equipment of uniform fertilization, comprises frame 1, support 2, roller 3 and fertilization bin 10, the bottom of frame 1 is equipped with support 2, and the lower end of support 2 is equipped with roller 3, The sidewall of support 2 is equipped with the drive motor 4 that is used to drive roller 3 to rotate, and the lower surface of frame 1 is equipped with soil-turning mechanism, and soil-turning mechanism comprises mounting plate 5, soil-turning motor 6, screw rod 7, slide block 8 and wire. Rod 9, the lower surface of the frame 1 is hinged with a mounting plate 5, one side of the mounting plate 5 is fixedly connected with a soil turning motor 6, the shaft end of the soil turning motor 6 is fixedly connected with a screw rod 7, and the lower end of the screw rod 7 is inserted into the soil , when the soil turning motor 6 is running, it drives the screw rod 7 to rotate, so as to...

Embodiment 2

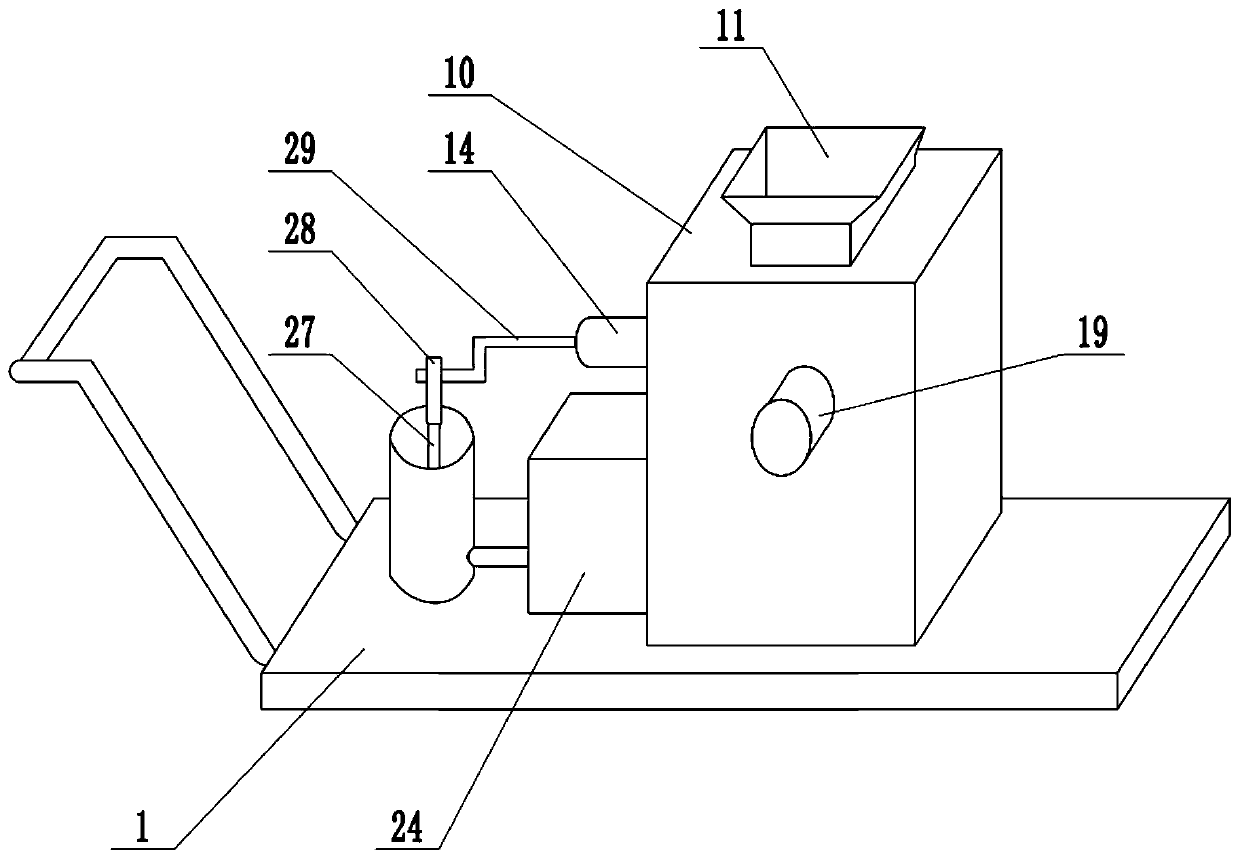

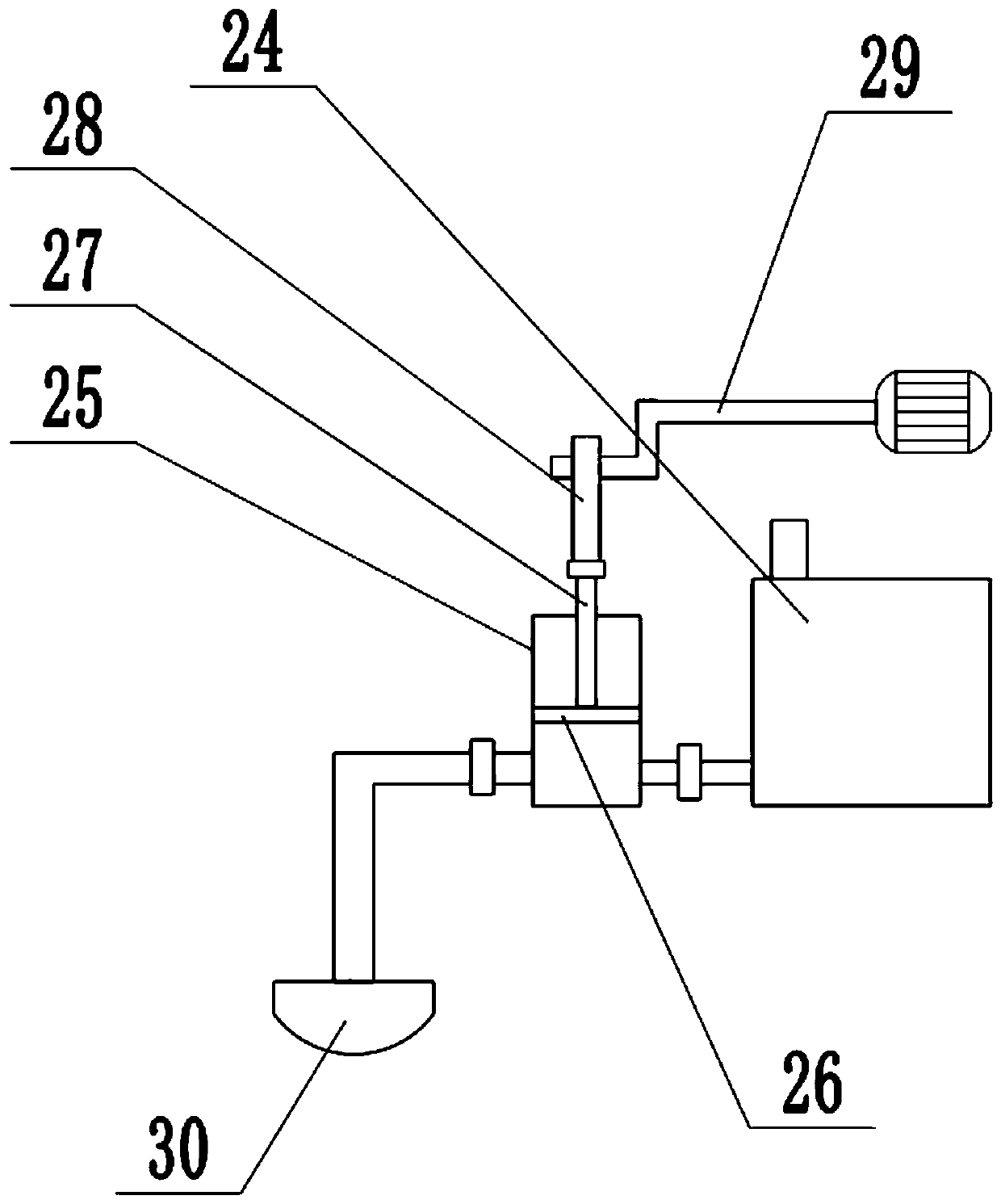

[0023] On the basis of Embodiment 1, a sprinkling mechanism is also installed on the upper surface of the frame 1, and the sprinkling mechanism includes a water tank 24, a piston cylinder 25, a piston plate 26, a piston rod 27, a connecting rod 28, a crankshaft 29 and a shower nozzle 30, and the frame The upper surface of frame 1 is fixedly connected with a water tank 24 for storing water. The upper surface of frame 1 is also fixedly connected with a piston cylinder 25, and the inside of the piston cylinder 25 is slidingly connected with a piston plate 26. The piston plate 26 can slide up and down, and the piston plate The upper surface of 26 is fixedly connected with piston rod 27, and the top of piston rod 27 is hinged with connecting rod 28, and the left shaft extension end of biaxial motor 14 is fixedly connected with crankshaft 29, and connecting rod 28 is connected with crankshaft 29 rotations, and the piston barrel 25 The right side wall communicates with the water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com