Equipment for applying rust-proof oil to stator core

A stator core and anti-rust oil technology, applied in the manufacture of stator/rotor bodies, coatings, devices for coating liquid on the surface, etc., can solve the problems of low efficiency of manual oiling, corrosion, etc., and achieve high oiling efficiency , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

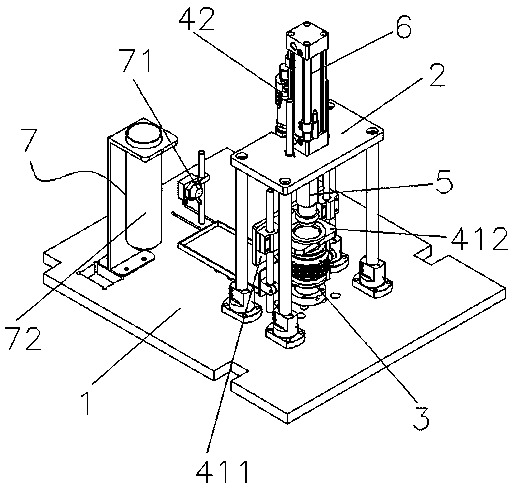

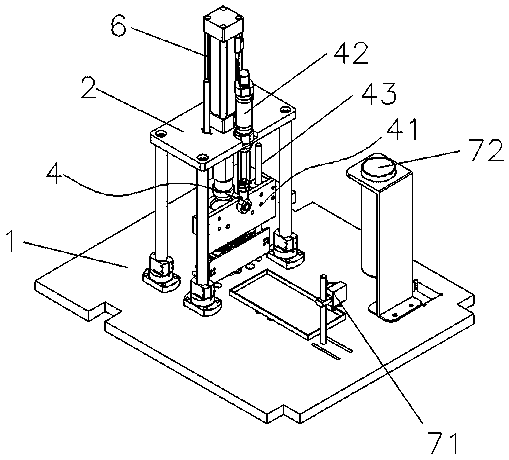

[0017] Embodiment: Anti-rust oil coating equipment for stator iron core (see attached Figure 1-3 ), including a workbench 1, a frame 2 is set on the workbench 1, a stator fixing seat 3 is set on the workbench 1, and the stator fixing seat 3 is movably connected with the workbench 1, and the machine A stator clamp 4 is arranged on the frame 2, the stator clamp 4 is fixedly connected with the frame 2, an oiling brush 5 is arranged on the frame 2, and an oiling cylinder is arranged on the oiling brush 5 6. The oiling brush 5 is fixedly connected to the oiling cylinder 6, the oiling cylinder 6 is fixedly connected to the frame 2, and the fuel injector 7 is arranged on one side of the frame 2, and the oil spraying The device 7 is fixedly connected with the workbench 1, and a rotating electric machine 8 is arranged under the workbench 1, and the rotating electric machine 8 is connected with the stator fixing seat 3. The fuel injector 7 includes an oil injection nozzle 71 and an oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com