Warehouse stock sorting and separating management method and system

A management method and warehouse technology, applied in the management method of warehouse storage and picking separation and its system field, can solve problems such as low warehouse efficiency, poor warehouse utilization rate, and unreasonable warehouse structure layout, so as to improve shipping efficiency and reduce The effect of improving the damage rate and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

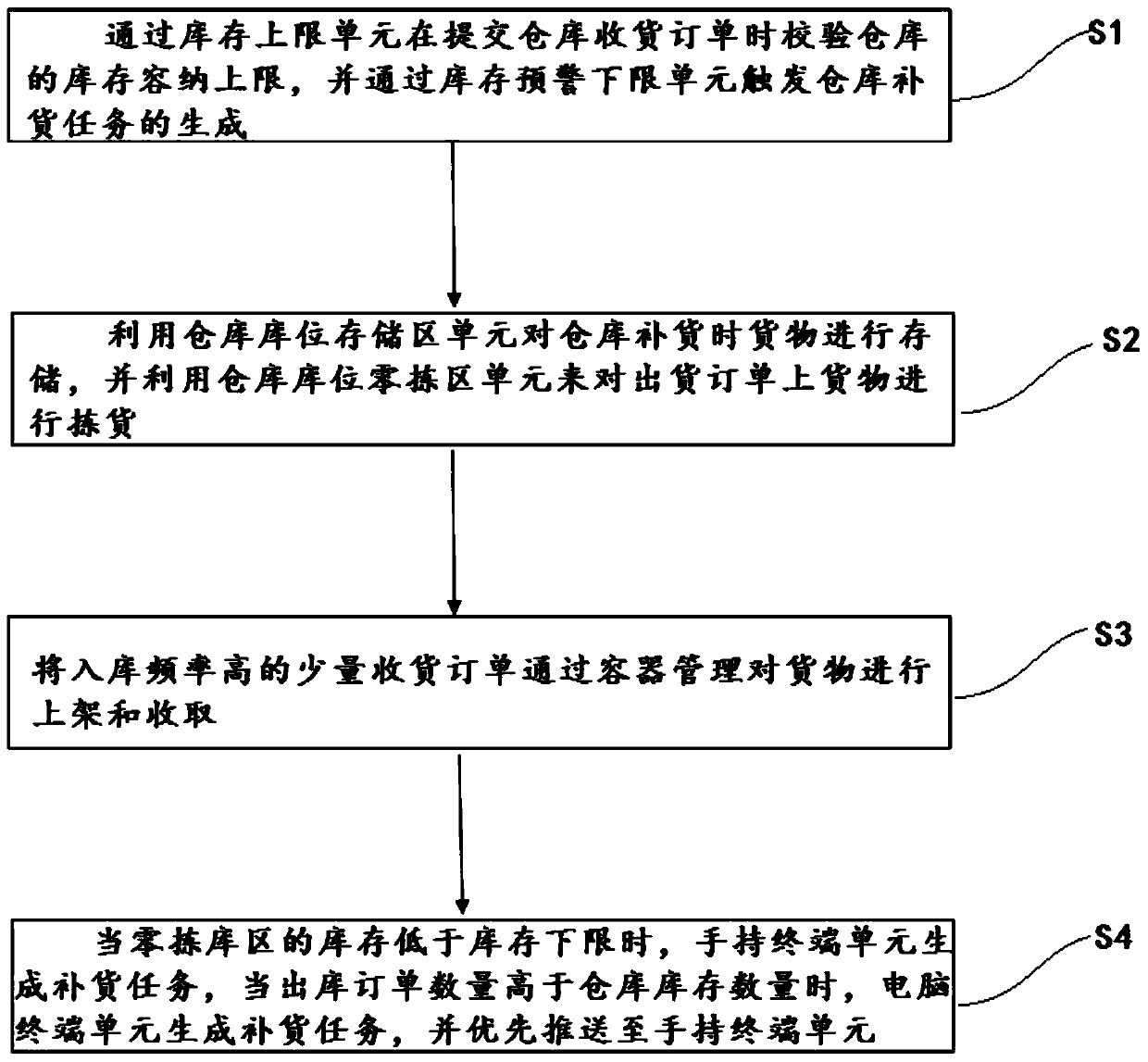

[0031] An embodiment of the present invention provides a management method for warehouse storage and picking separation, such as figure 1 As shown, the management method includes:

[0032] S1: Verify the upper limit of the warehouse's inventory capacity when submitting the warehouse receipt order through the upper limit unit of the inventory, and trigger the generation of the warehouse replenishment task through the lower limit unit of the inventory warning;

[0033] Specifically, the set upper limit of inventory capacity and lower limit of inventory warning are respectively located in the product data maintenance under the product management page. The maintenance of product data also includes important logistics information such as the owner, product code, and product name. By setting the upper limit of inventory capacity and The inventory warning lower limit unit can make dynamic adjustments to the shipment and replenishment of goods more conveniently, and keep the warehouse...

Embodiment 2

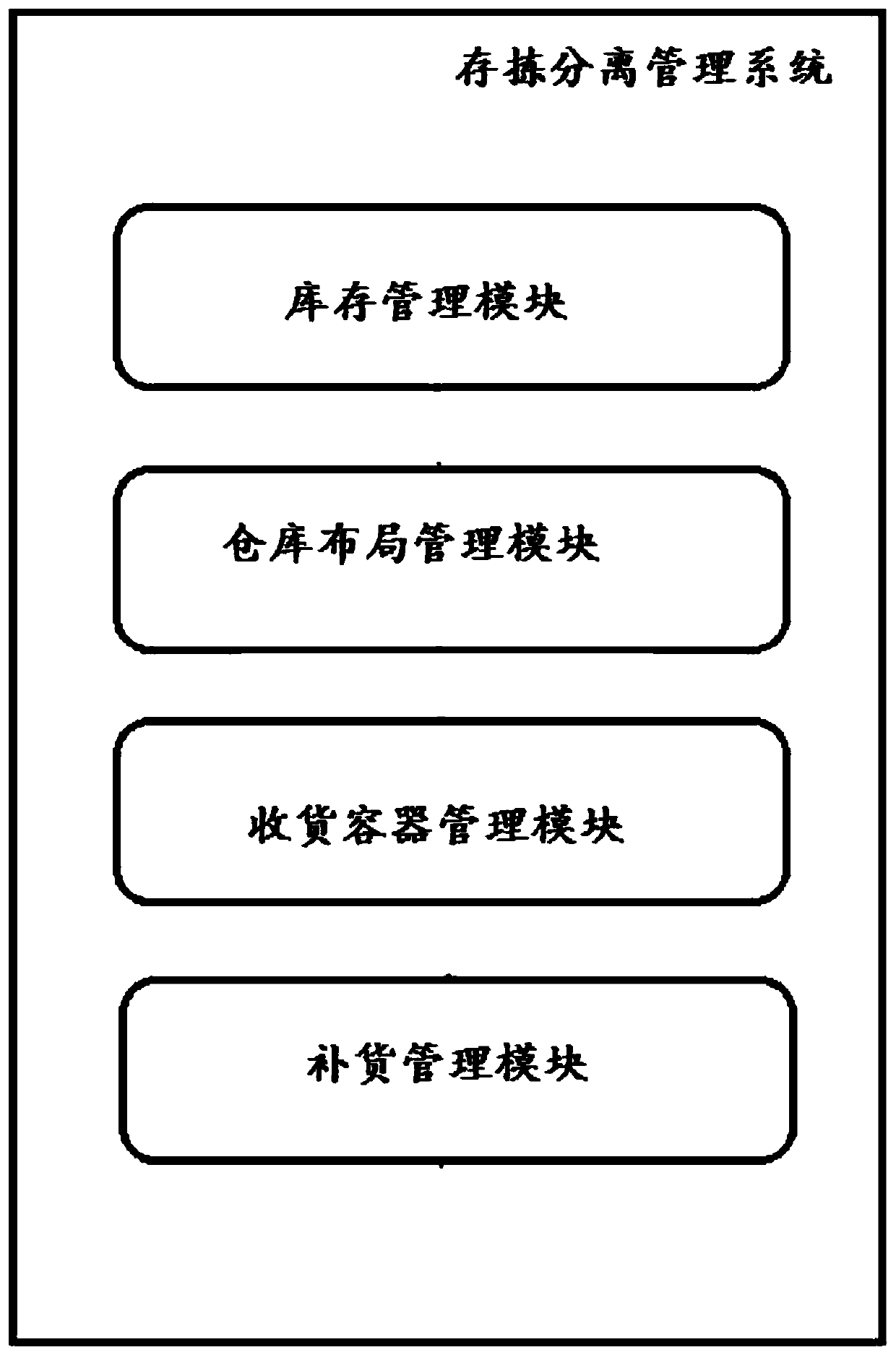

[0041] An embodiment of the present invention provides a management system for warehouse storage and picking separation, such as figure 2 As shown, the management system includes:

[0042] Inventory management module, comprising an inventory upper limit unit and an inventory warning lower limit unit, the inventory upper limit unit is used to check the inventory capacity upper limit of the warehouse when submitting the warehouse receipt order, and the inventory early warning lower limit unit is used to trigger the warehouse replenishment task generate;

[0043] The warehouse layout management module includes a warehouse location storage area unit and a warehouse location zero-picking area unit. The warehouse location storage area unit is used for storing goods when the warehouse is replenished. Picking of goods on shipping orders;

[0044] The receiving container management module is used for a small number of receiving orders with high frequency of warehouse receiving and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com