Energy-saving hearth provided with air thermal insulating layer and thermal radiation reflecting layer and preparation method thereof

A technology of heat radiation reflection layer and air heat insulation layer, which is applied in the furnace, lighting and heating equipment, furnace and other directions, can solve the problems of slow heating rate, limited energy saving effect, and large thermal conductivity of electric furnace, so as to prevent heat radiation and improve Energy saving effect and effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

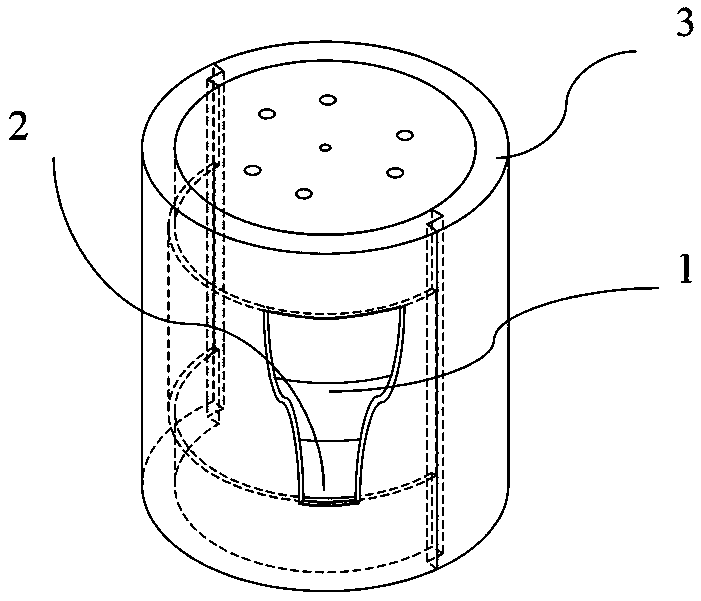

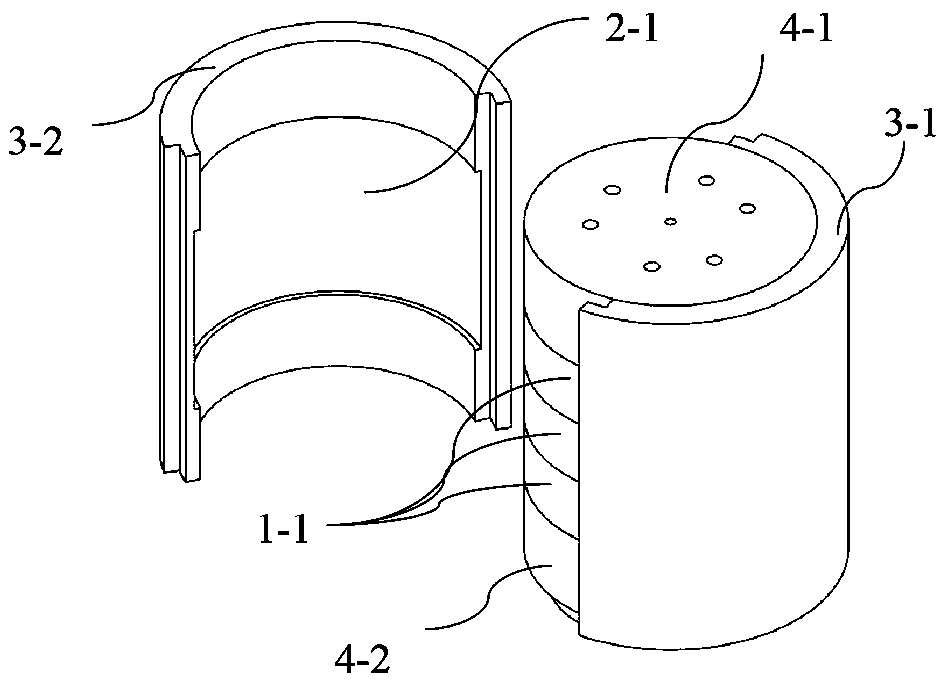

[0025] like figure 1 , 2 As shown, an energy-saving furnace mold with air heat insulation and heat radiation reflection layer is composed of refractory lining 1, air heat insulation layer 2, heat insulation layer 3, furnace top 4-1 and furnace bottom 4-1. The refractory lining 1 can be divided into three layers 1-1 superimposed and formed, and is located between the furnace top 4-1 and the furnace bottom 4-2. The insulation layer 3 is formed by combining two semicircular sheets 3-1 and 3-2, and wraps the refractory inner lining 1, the furnace top 4 and the furnace bottom 5 into one. Open a groove along the inner circumference in the middle of the inner concave surface of the insulation layer 3, the thickness of the groove is 10mm, and the height of the groove is consistent with the height of the refractory lining 1. The inner groove of the thermal insulation layer 3 and the outer side of the refractory inner lining 1 form the air heat insulation layer 2 . Glass microspheres...

Embodiment 2

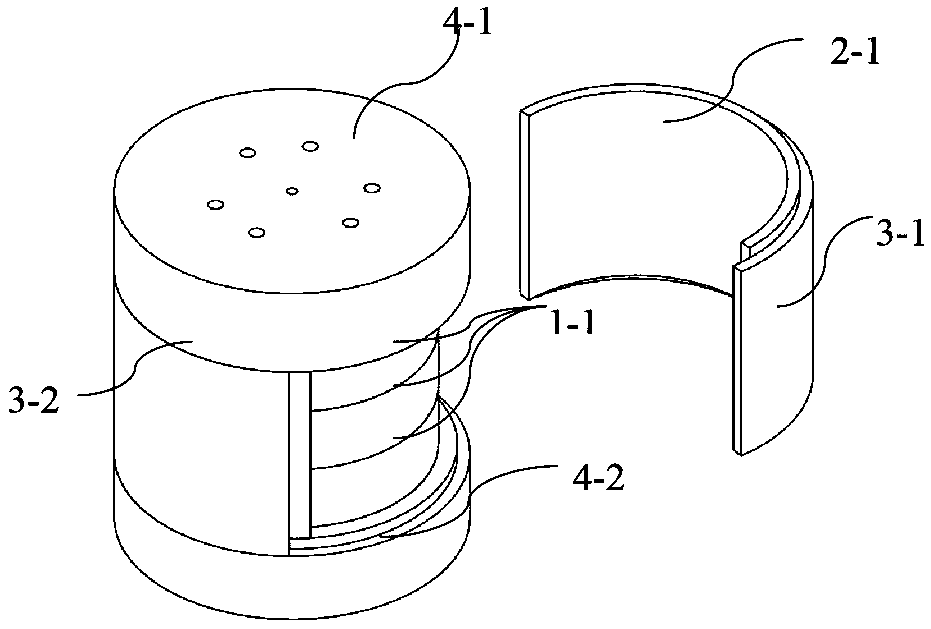

[0027] like image 3 As shown, a kind of energy-saving furnace mold with air heat insulation and heat radiation reflective layer is made of refractory inner lining 1, air heat insulation layer 2, insulation layer 3, furnace top 4-1 and furnace bottom 4-1. The refractory lining 1 can be divided into three layers 1-1 superimposed and formed, and is located between the furnace top 4-1 and the furnace bottom 4-2. The insulation layer 3 is formed by combining two semicircular sheets 3-1 and 3-2 and is located between the furnace top 4-1 and the furnace bottom 4-2, and wraps the refractory lining 1 into one. In the middle of the outer convex surface of the refractory lining 1, a groove is formed along the outer circumference, the thickness of the groove is 20mm, and the height of the groove is consistent with the height of the refractory lining 1. The inner side of the thermal insulation layer 3 and the outer groove of the refractory inner lining 1 form the air heat insulation laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com