Gas stove and control method thereof

A control method and technology for gas stoves, applied in the field of gas stoves, can solve problems such as misoperation, gas leakage, failure to maintain pressing action, etc., and achieve the effects of improving safety and simplifying ignition steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this example, if figure 1 As shown, a gas stove includes a thermocouple, a pulser, an ignition needle, a gas pipeline, and a first valve body and a second valve body connected to the gas pipeline, and the second valve body is connected to the thermocouple and the second valve body respectively. The delayers are connected in series and opened by a switch structure independent of the first valve body. When the gas pipeline is turned on, the second valve body is subjected to the thermal electromotive force generated by the thermocouple within the time set by the delayer. The role is to keep the gas pipeline open.

[0040] In this embodiment, the switch structure of the second valve body is set independently of the first valve body, which reduces the air leakage caused by accidental operation. The opening time of the second valve body during the fire process, and when the gas is accidentally extinguished, the second valve body is controlled to close by the thermoelectri...

Embodiment 2

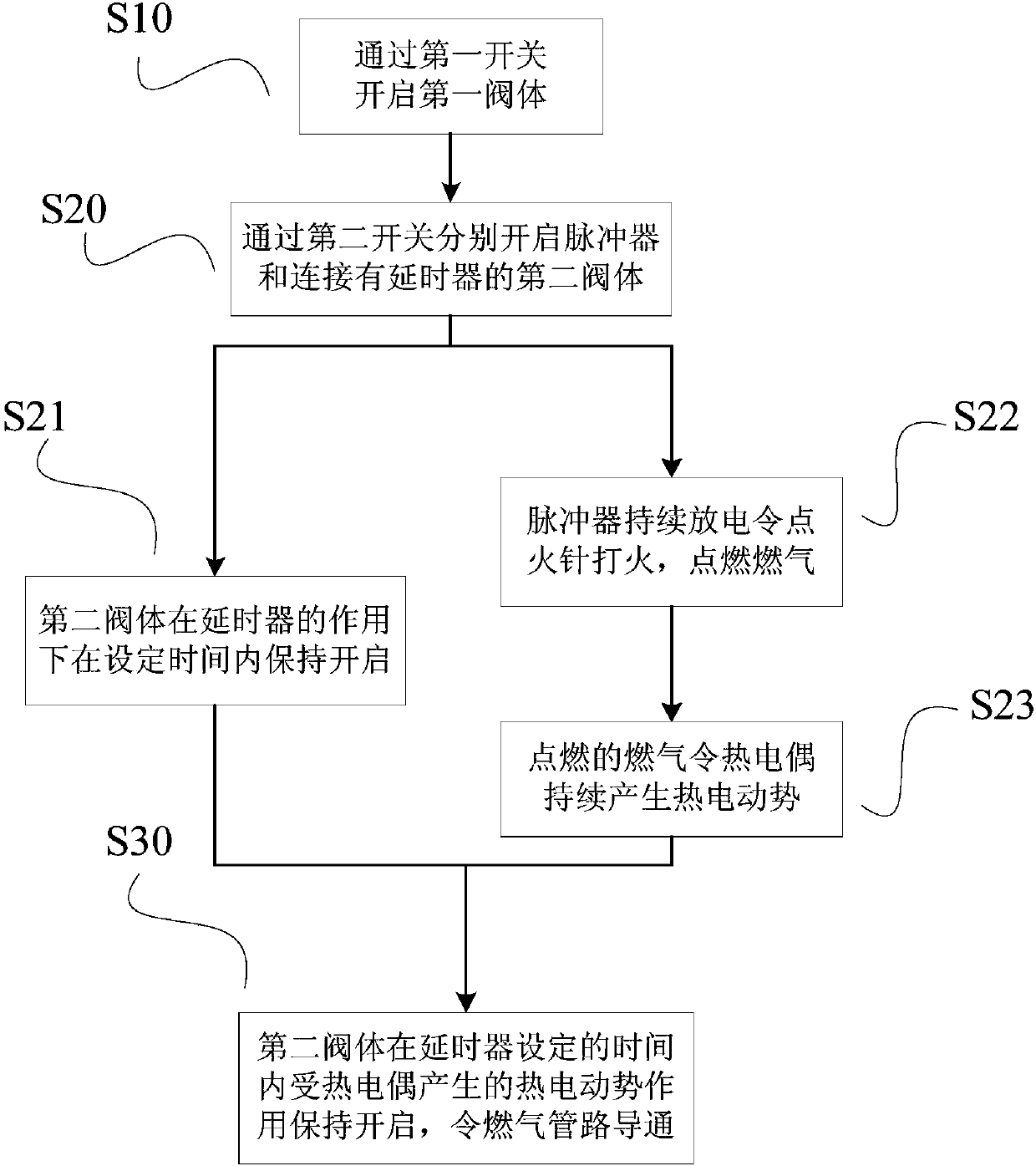

[0054] In this example, if figure 2 As shown, a control method of a gas stove is also provided, the first valve body is connected in series with the second valve body, and connected to the gas pipeline, and when the first valve body is opened, a delayer is connected to the opening The second valve body of the thermocouple and the second valve body of the thermocouple are ignited at the same time, so that the second valve body is kept open by the thermal electromotive force generated by the thermocouple within the setting time of the delayer.

[0055] In this embodiment, when the first valve body is opened, one-button ignition can be realized through the second switch, and it is not necessary to perform operations such as rotation, pressing, and pressing and maintaining when a single knob is used in the prior art, which simplifies the ignition steps At the same time, a delayer and a thermocouple are added to the second valve body to facilitate more accurate control of the on-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com