Automatic transmission gear shifting mechanism

A technology of automatic transmission and shifting mechanism, which is applied to mechanical equipment, transmission device control, components with teeth, etc., can solve the problem that the relative position of the self-locking device and the elastic device cannot be adjusted, the processing accuracy and installation accuracy are high, and The problem of high production costs, to achieve the effect of cheap processing methods, reduce processing accuracy and installation accuracy, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

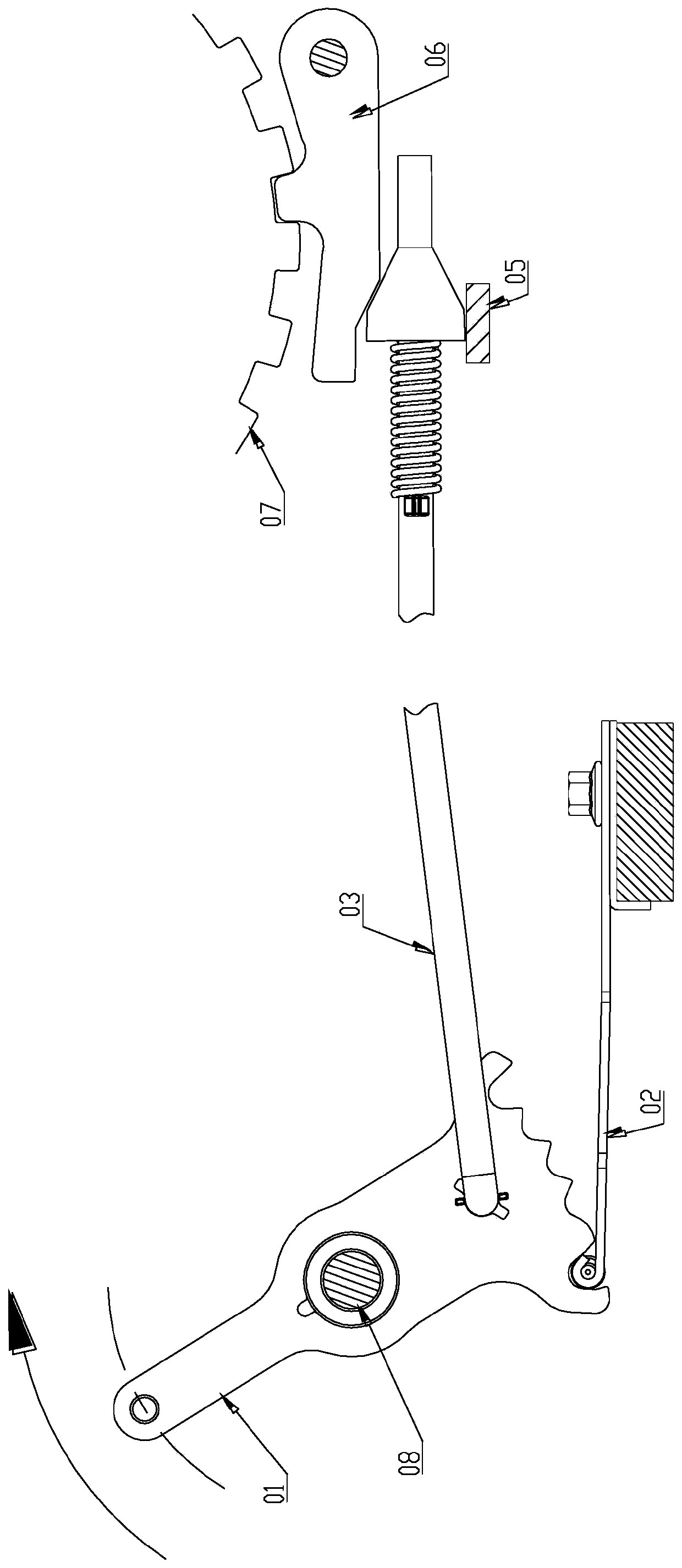

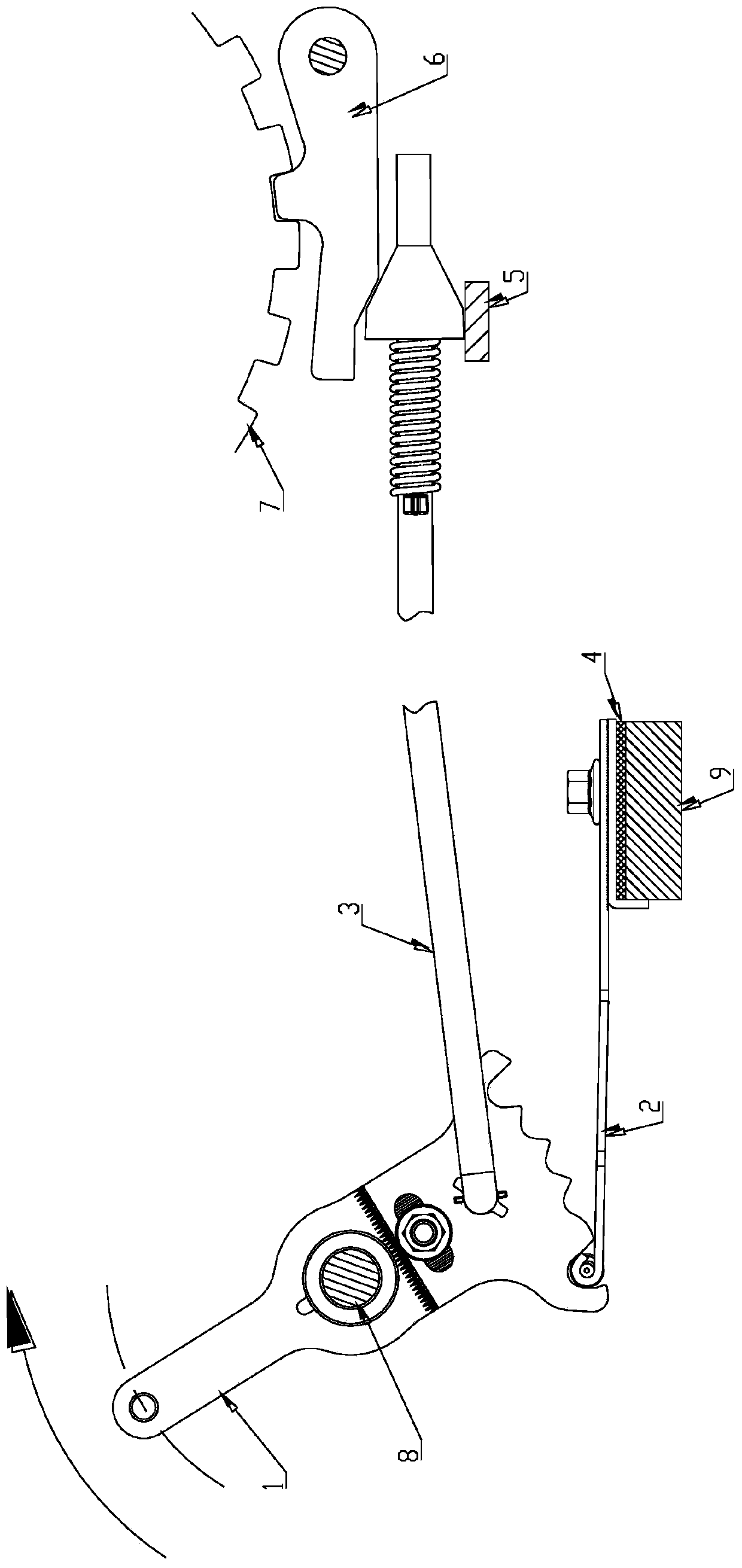

[0038] refer to figure 2 , the shifting mechanism includes a self-locking device 1 driven by the shift lever 8, an elastic device 2 for locking the self-locking device, and a parking device driven by the self-locking device 1 to move along the guide device 5 when the P gear is engaged. Car bar 3, the parking pawl 6 that rotates around the rotating shaft under the action of the cone of the parking bar 3, and the parking ratchet 7 that links to each other with the transmission shaft of the gearbox.

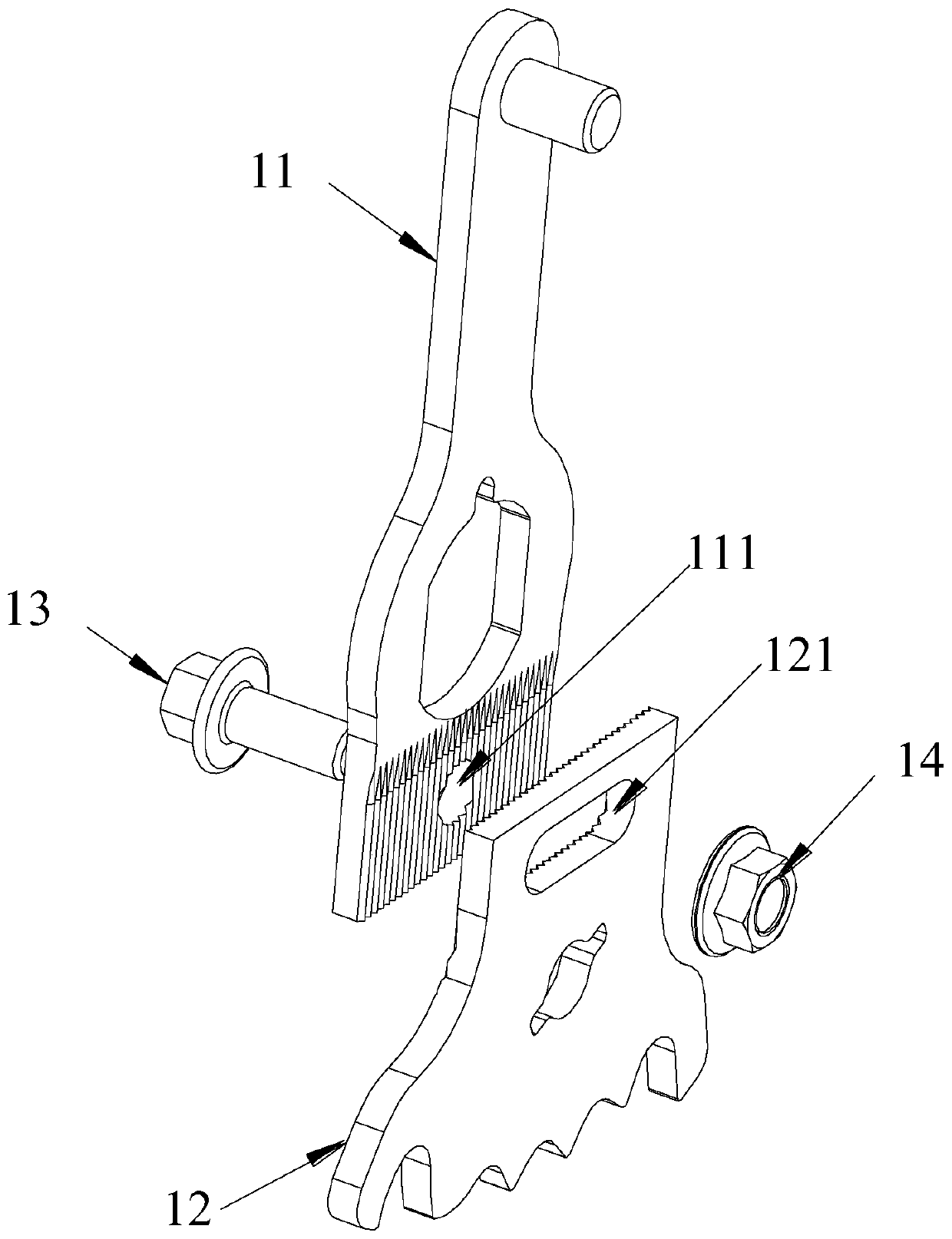

[0039] refer to image 3 , Figure 4 and Figure 5 The self-locking device 1 includes a driving part 11 that cooperates with the shift shaft 8 and a locking part 12 that fits in the groove of the elastic device 2. The driving part 11 and the locking part 12 are paired by a first bolt 13 and a nut 14. It applies pressure to fit together. In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com