Magnetically controlled surface-variable film and manufacturing method thereof

A magnetic control and variable technology, applied in the direction of magnetic coatings, coatings, etc., can solve problems such as impossible and dynamic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the drawings and specific embodiments.

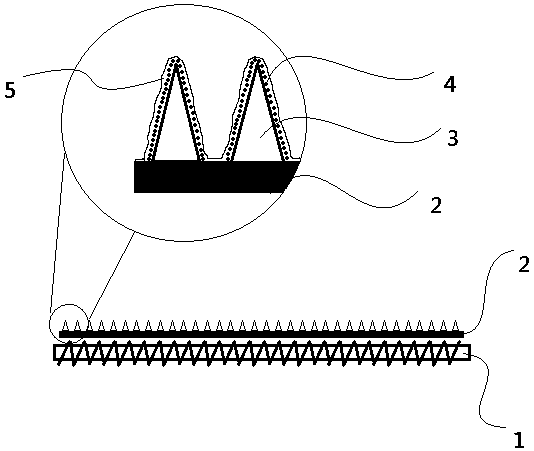

[0008] A magnetically controlled surface variable film, comprising an electromagnet control layer 1, a glass supporting base layer 2, a variable micro-pillar array 3, a polystyrene nanoparticle coating 4, and a lubricant coating 5; the electromagnet control The layer is located on the bottom surface of the surface variable film; the glass support base layer is located above the electromagnet control layer, with a thickness of 1 mm; the variable micro-pillar array is located above the glass support base layer and includes two Triangular pyramid-shaped micro-pillars with orderly and uniformly distributed and equidistant arrangement, the height of the micro-pillars is 500 micrometers, the maximum diameter of the contact with the glass supporting base layer is 15 micrometers, between adjacent micro-pillars The distance of the micro-pillars is 30 microns; the polys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com