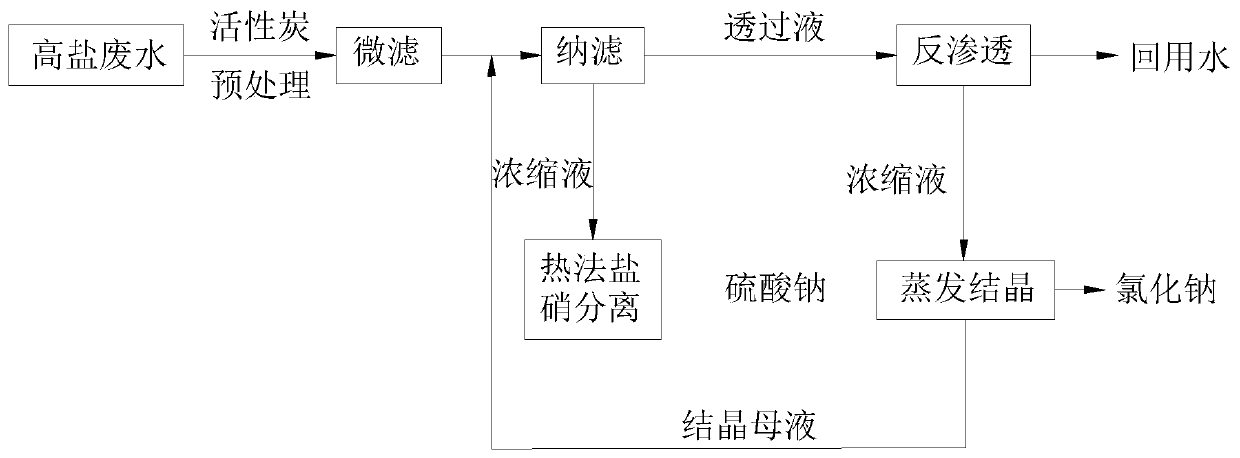

Method for separating sodium chloride and sodium sulfate in high-salinity wastewater in coastal industrial zone

A high-salt wastewater, sodium sulfate technology, applied in chemical instruments and methods, alkali metal chlorides, general water supply conservation, etc. High recovery rate and high purity of inorganic salts, etc., to achieve the effects of stable operation, improved recovery rate and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0053] Take the salt concentration of high-salt wastewater in Tianjin Binhai Industrial Zone as an example, which is about 100g / L:

[0054] The first step: set up two reaction pools in the high-salt wastewater discharge area of the coastal industrial belt, respectively the first reaction pool 1 and the second reaction pool 2, and lay an activated carbon particle layer on the bottom of the first reaction pool 1 according to the above operation, The bottom and middle of the second reaction tank 2 are paved with double layers of activated carbon particles. Through activated carbon pretreatment, part of the organic matter and oil in the wastewater are removed. After testing the suspension in the upper layer of the second reaction tank 2, the TOC removal rate can reach 83.5 %, the removal rate of total oil can reach 93%, and the chroma is less than 50;

[0055] Step 2: Enter the pretreated waste water in the second reaction pool 2 into the spiral microfiltration tube 6 to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com