Sorting and sorting feeding structure and working method of double-line bag

A thread wrapping and feeding technology is applied in the field of sorting, classifying and feeding structure for double thread wrapping, which can solve the problems of combing effect of double thread wrapping, unfavorable packaging work, inability to improve the packing and packaging work efficiency of double thread wrapping products, etc. The effect of packaging work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

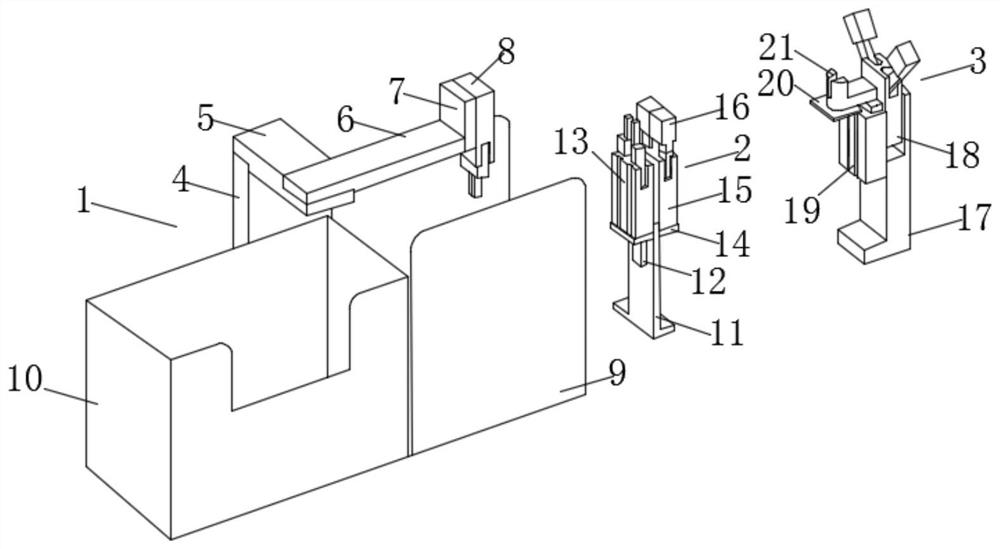

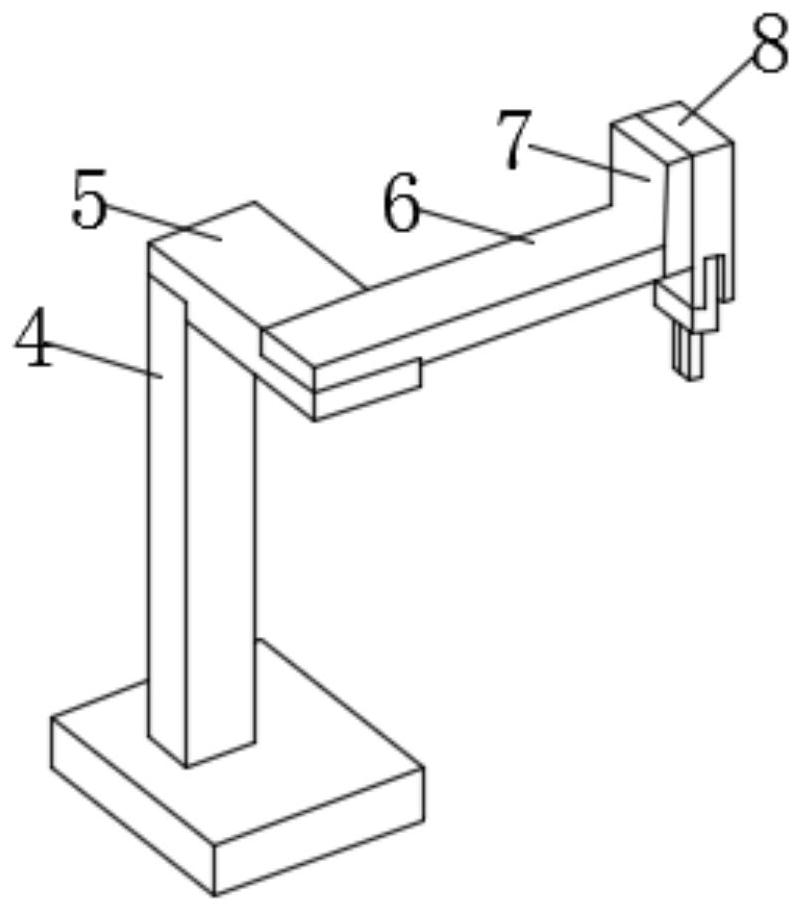

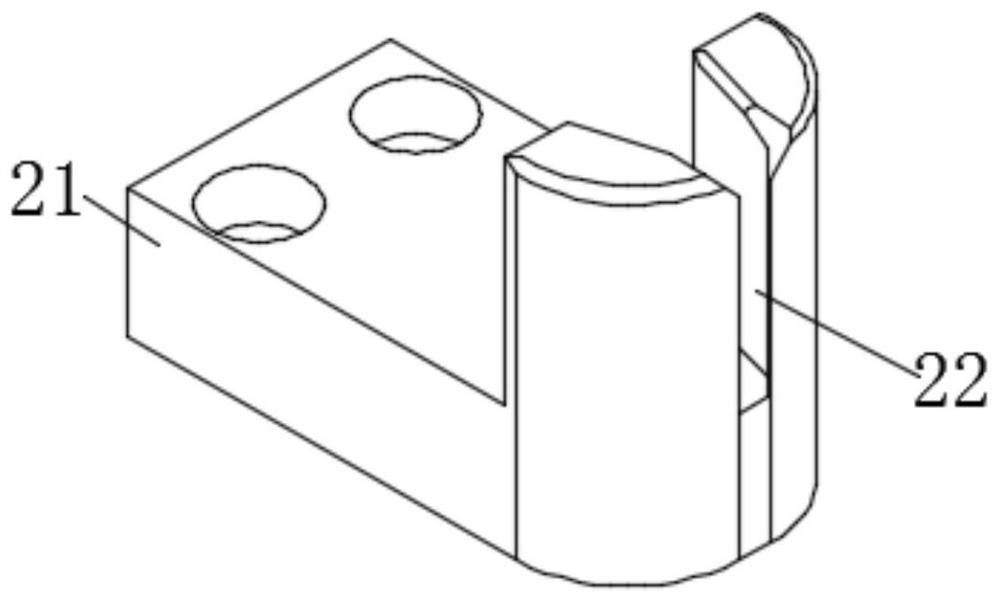

[0018] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: the sorting and sorting feeding structure of the double-wire bag includes a material receiving mechanism 1, a wire management mechanism 2 and a wire delivery mechanism 3, and the material receiving mechanism 1 is formed by the first fixed support plate 4 , the first horizontal plate 5, the second horizontal plate 6, the fixed side plate 7, the finger clamp 8 for picking and sorting, the good product frame 9 and the defective product frame 10. The top fixing screw of the first fixed support plate 4 is fixedly installed with The first horizontal plate 5, the end of the first horizontal plate 5 away from the first fixed support plate 4 is fixed with a second horizontal plate 6 by screws, and the end of the second horizontal plate 6 away from the first horizontal plate 5 is fixed A fixed side plate 7 is installed, and the side of the fixed side plate 7 far away from the second hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com