Clamping device for sputtered slide coating tensile force tests

A technology of tension testing and clamping device, which is applied in the field of laboratory tools, can solve the problems of difficult clamping, inconvenient observation and other experiments, and achieve the effect of convenient detection, convenient installation and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

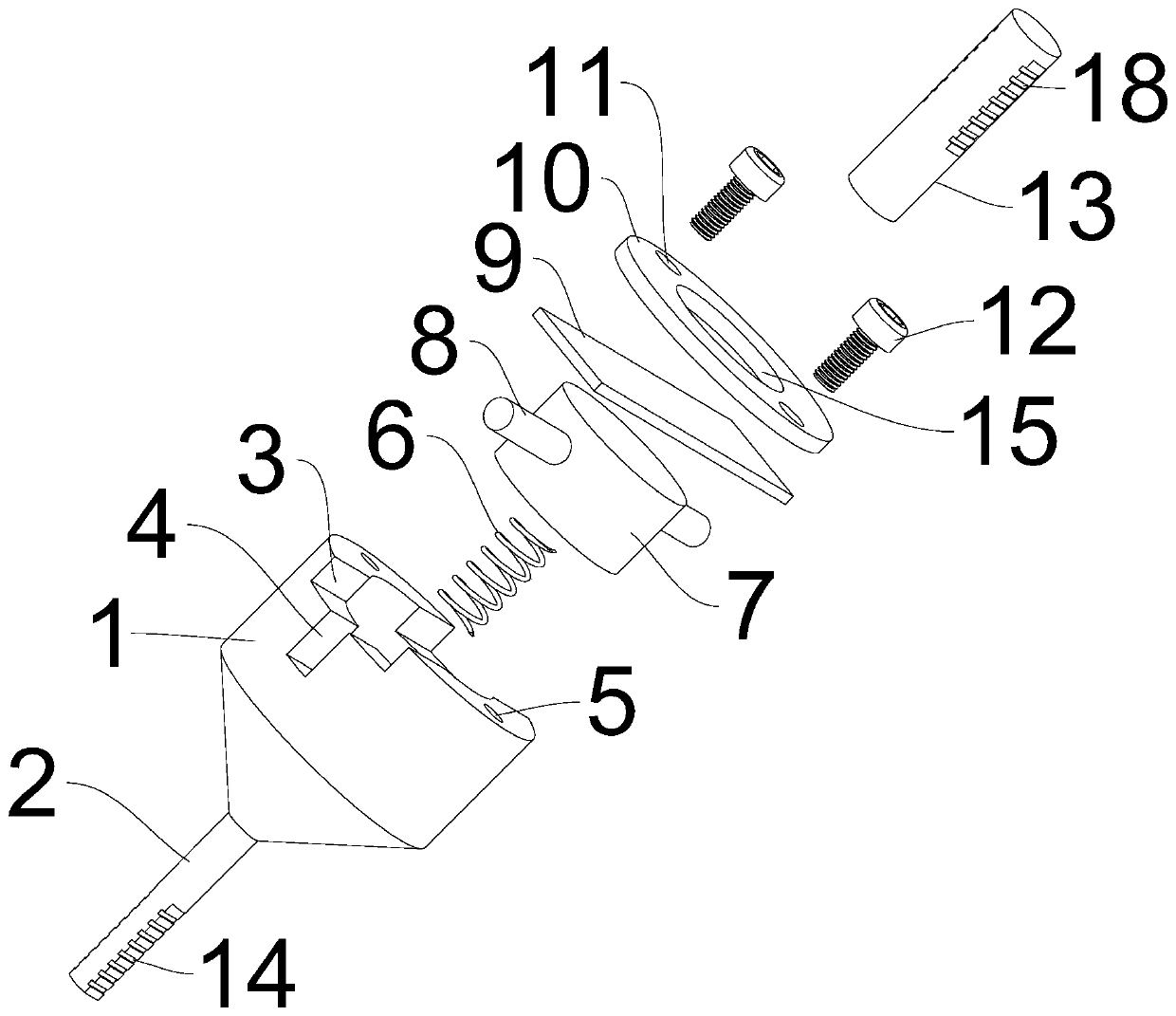

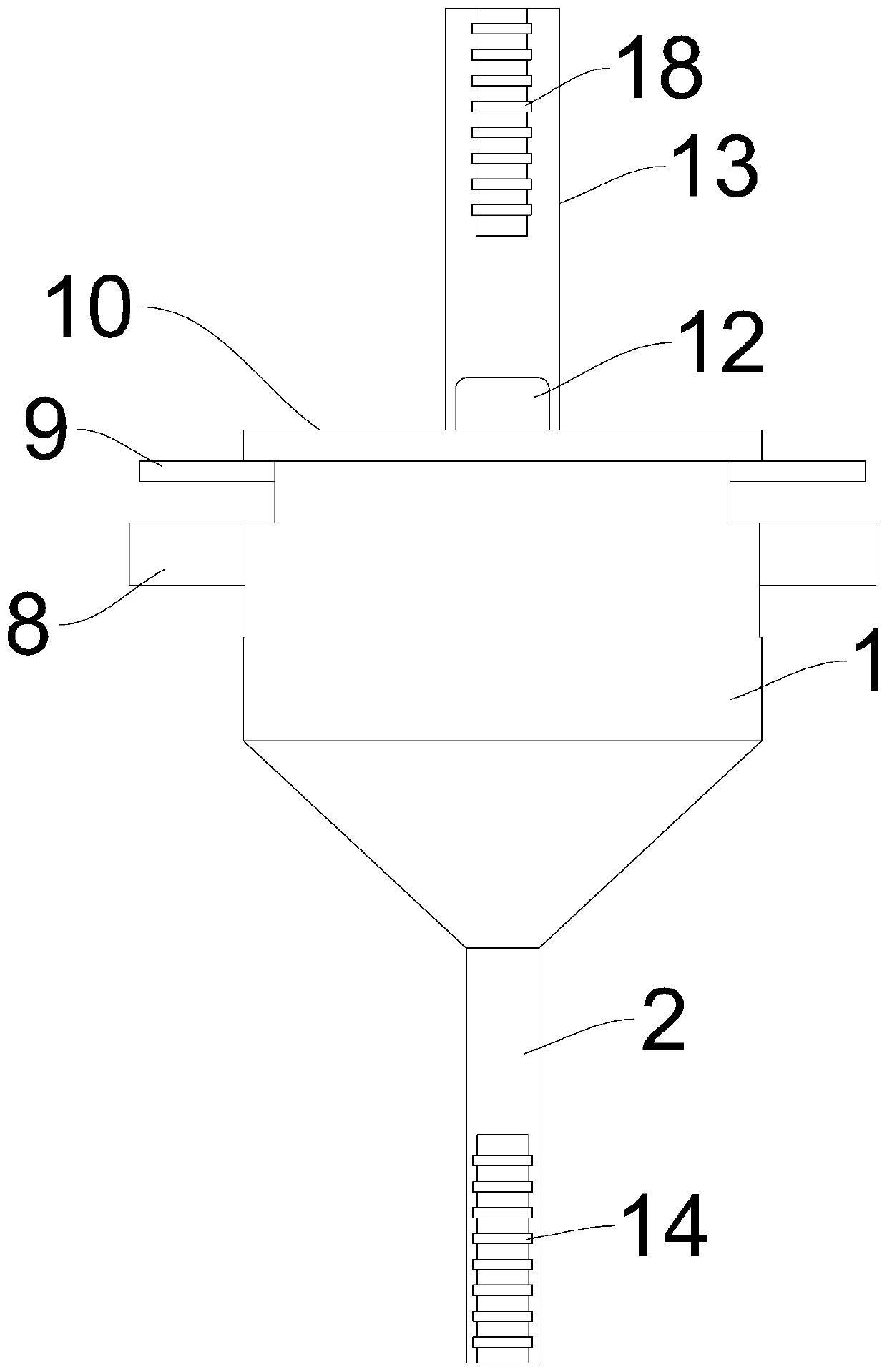

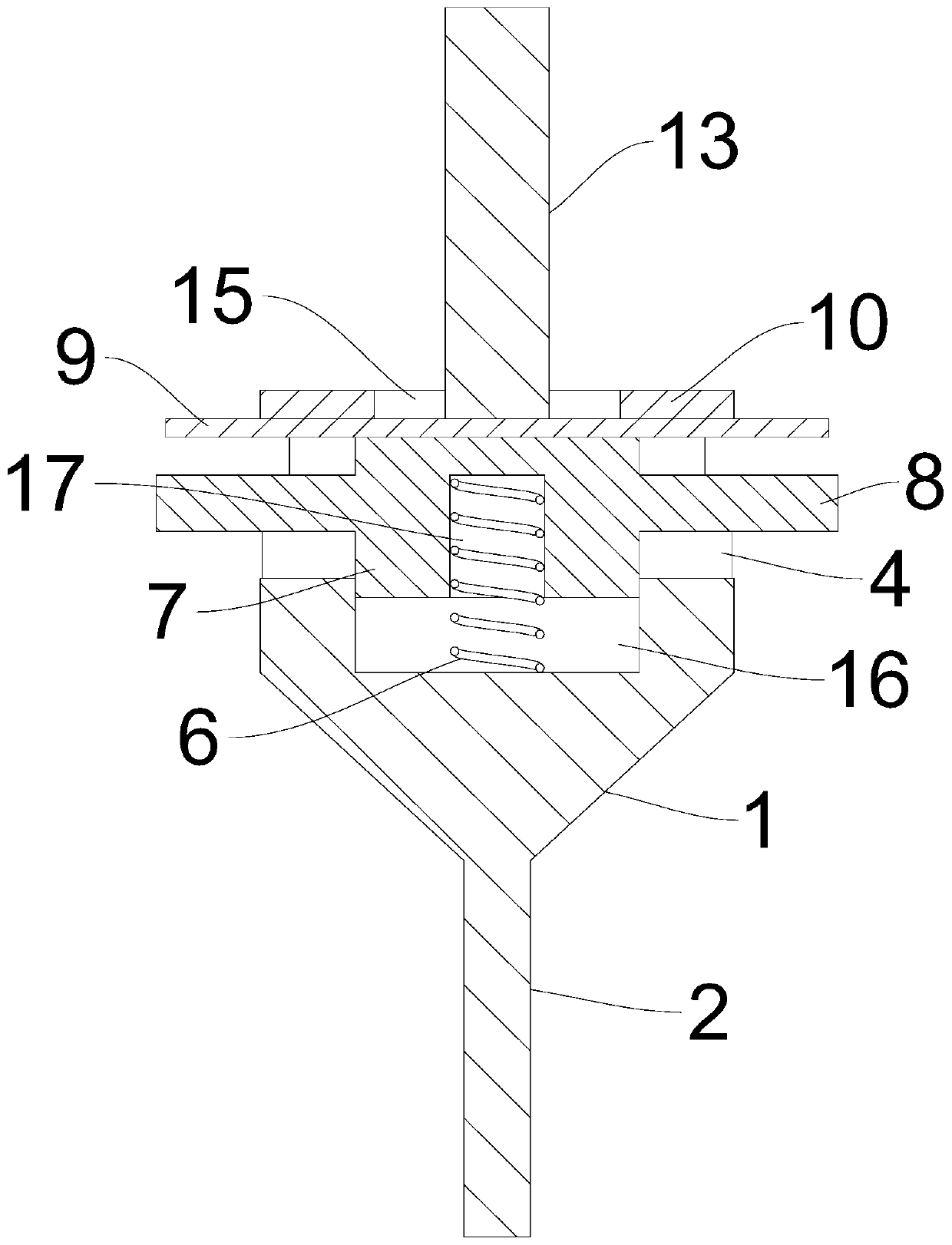

[0030] Such as Figure 1-4 As shown, this embodiment provides a clamping device for sputtering slide glass coating tensile test, including a clamping body 1 , a cover plate 10 and a base 2 .

[0031] Specifically, one end of the clamping body 1 is provided with a placement groove 3 for putting in the slide glass 9, the placement groove 3 is square, and the placement groove 3 is connected at both ends, and the slide glass 9 can be put into the placement slot from both ends. In the groove 3, a groove 16 is also provided in the placement groove 3, and a limiting component for limiting the slide glass 9 is arranged in the groove 16. The cover plate 10 is covered on the placement groove 3, and the cover plate 10 and the clamping body 1 Detachable connection, clamping the glass slide 9 by defining the components and the cover plate 10, the cover plate 10 is provided with a port 15 for exposing the glass slide 9, and the base 2 is integrally formed with the other end of the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com