Horizontal shaft top mounted pipe cleaning valve

A top-mounted, pigging technology, applied to the valve details, valve device, valve housing structure, etc., can solve the problems of difficulty in receiving the pig, complex structure, heavy weight, etc., to reduce the overall weight, simplify the overall structure, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

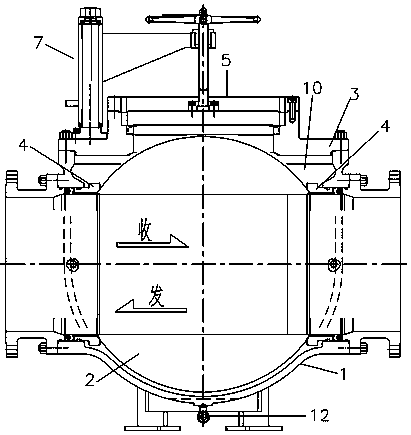

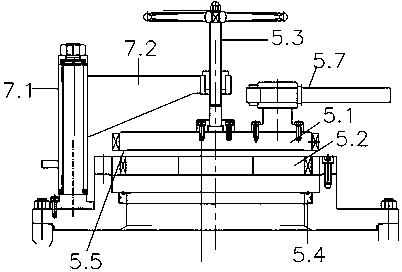

[0044] This embodiment provides a horizontal shaft top-mounted pigging valve, such as figure 1 , 2 As shown, it includes valve body 1, sphere 2, vent valve 11, blowdown valve 12, pressure gauge 13, valve cover 3, valve seat 4, opening and closing sealing mechanism 5, opening and closing interlocking mechanism 6, rotating mechanism 7 and ball control Mechanism 8, the positions and connections of each component are as follows:

[0045] The upper end of the valve body 1 is provided with a loading and unloading port 10. The diameter of the loading and unloading port 10 is slightly larger than the outer diameter of the ball 2. Both the ball 2 and the valve seat 4 are loaded into the valve body 1 through the loading and unloading port 10. The valve seat 4 is provided with a pull rod The hole and the valve seat 4 are symmetrically arranged on the upstream inlet end and the downstream outlet end of the valve body 1 , and the ball 2 is located between the valve seats 4 .

[0046] The...

Embodiment 2

[0069] On the basis of Example 1, the horizontal shaft top-mounted pigging valve also includes a hoisting mechanism 9, and the hoisting mechanism 9 includes a fixed vertical shaft 9.1, a beam 9.2, a reinforcing rib 9.3, a pulling line 9.4, a rotating sleeve 9.5 and Explosion-proof manual hoist 9.6, the lower end of the fixed vertical shaft 9.1 is fixed on the valve cover 3, the rotating sleeve 9.5 is movable sleeved on the upper end of the fixed vertical shaft 9.1, the beam 9.2 is fixed on the rotating sleeve 9.5, and the reinforcing rib 9.3 is fixed on the beam 9.2 and the rotating sleeve 9.5 Between, explosion-proof manual hoist 9.6 is connected on the beam 9.2, and traction line 9.4 is connected on the explosion-proof manual hoist 9.6. The ball 2 and the pig can be quickly hoisted into or out of the valve body 1 through the hoisting mechanism 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com