Combined ball valve element

A combined, spherical valve core technology, applied in valve details, valve devices, valve devices for absorbing fluid energy, etc., can solve the problem of low adjustment accuracy of circular through-hole valve cores, short valve service life, and easy erosion. and other problems, to avoid cavitation and high-speed media erosion, improve service life, and have a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

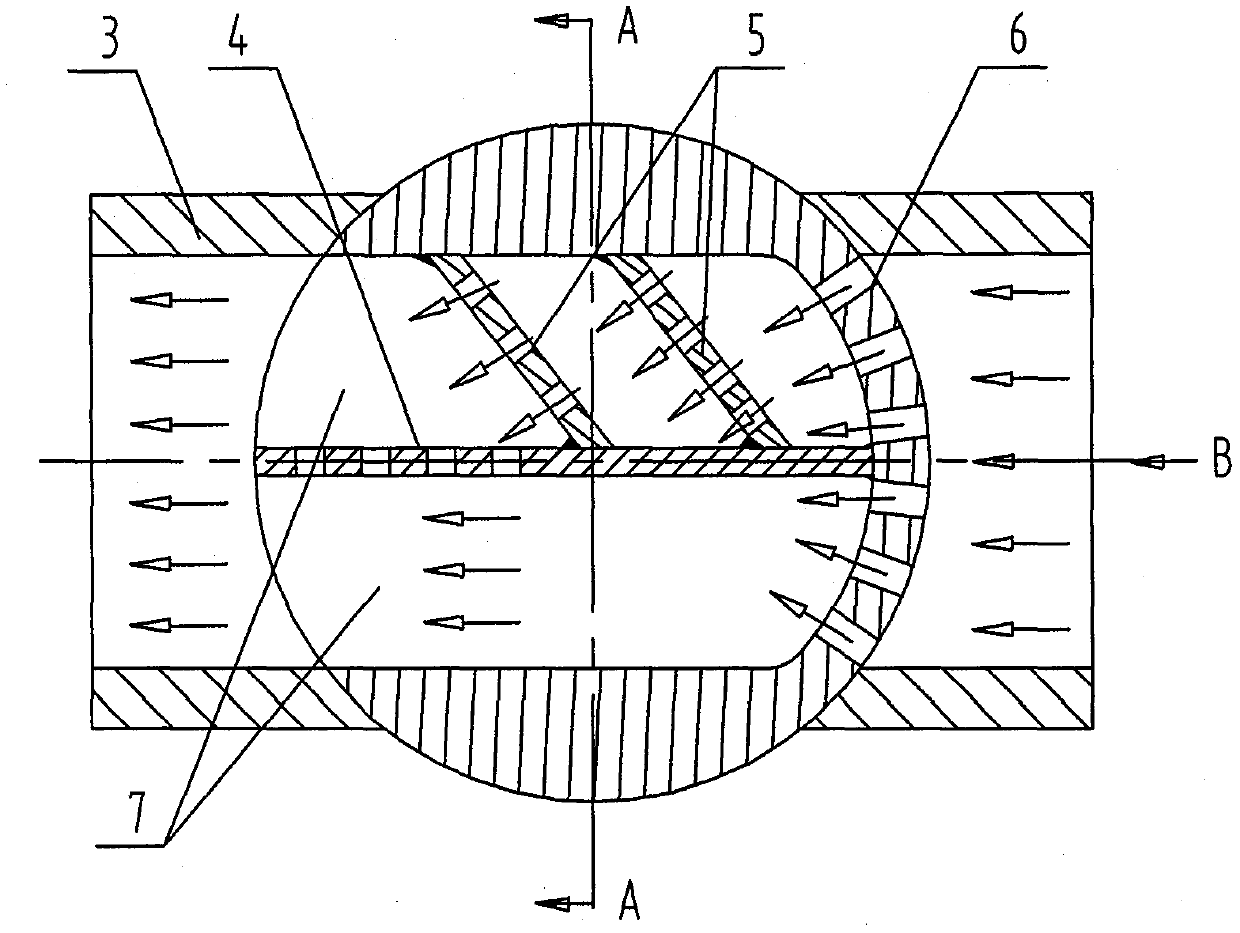

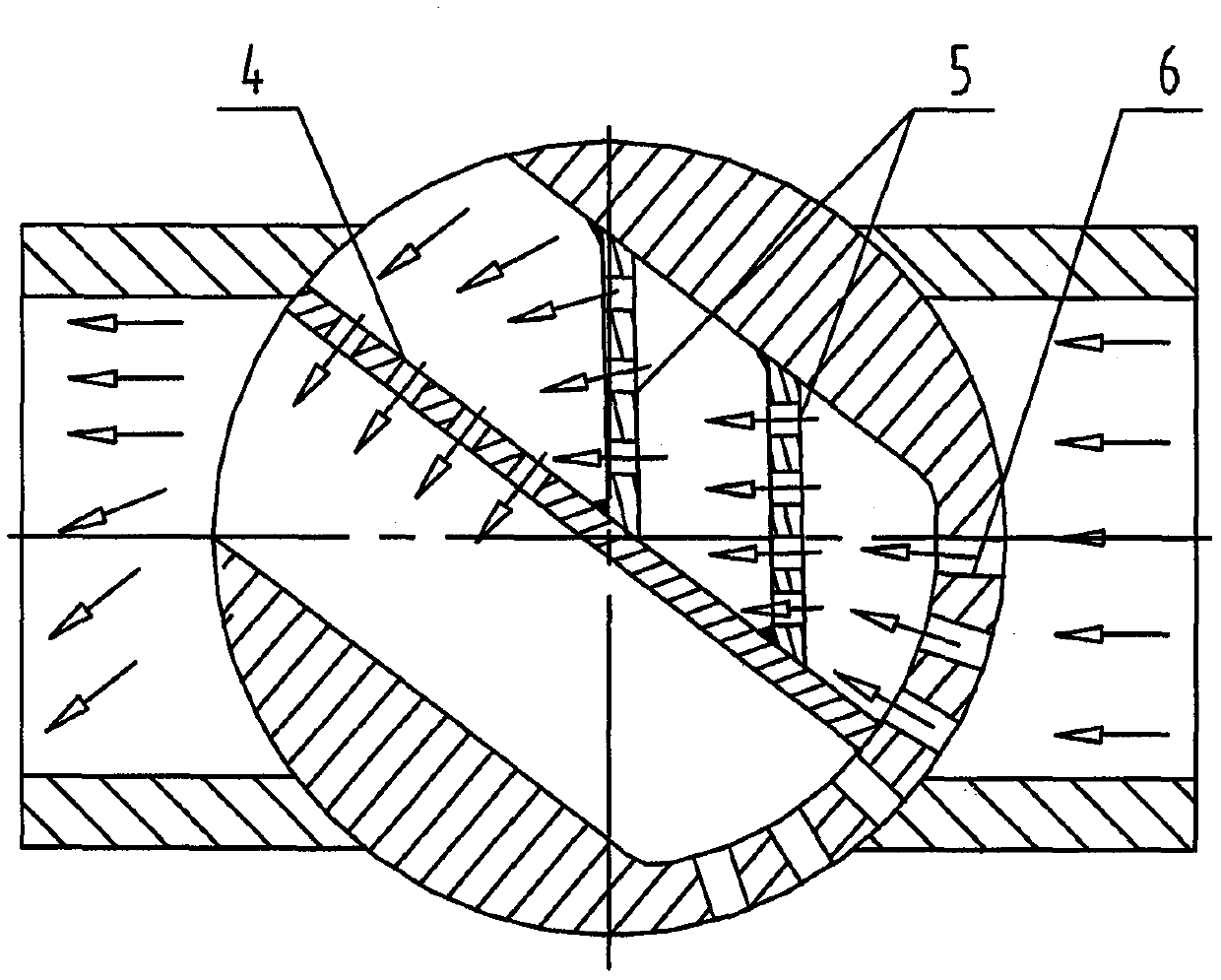

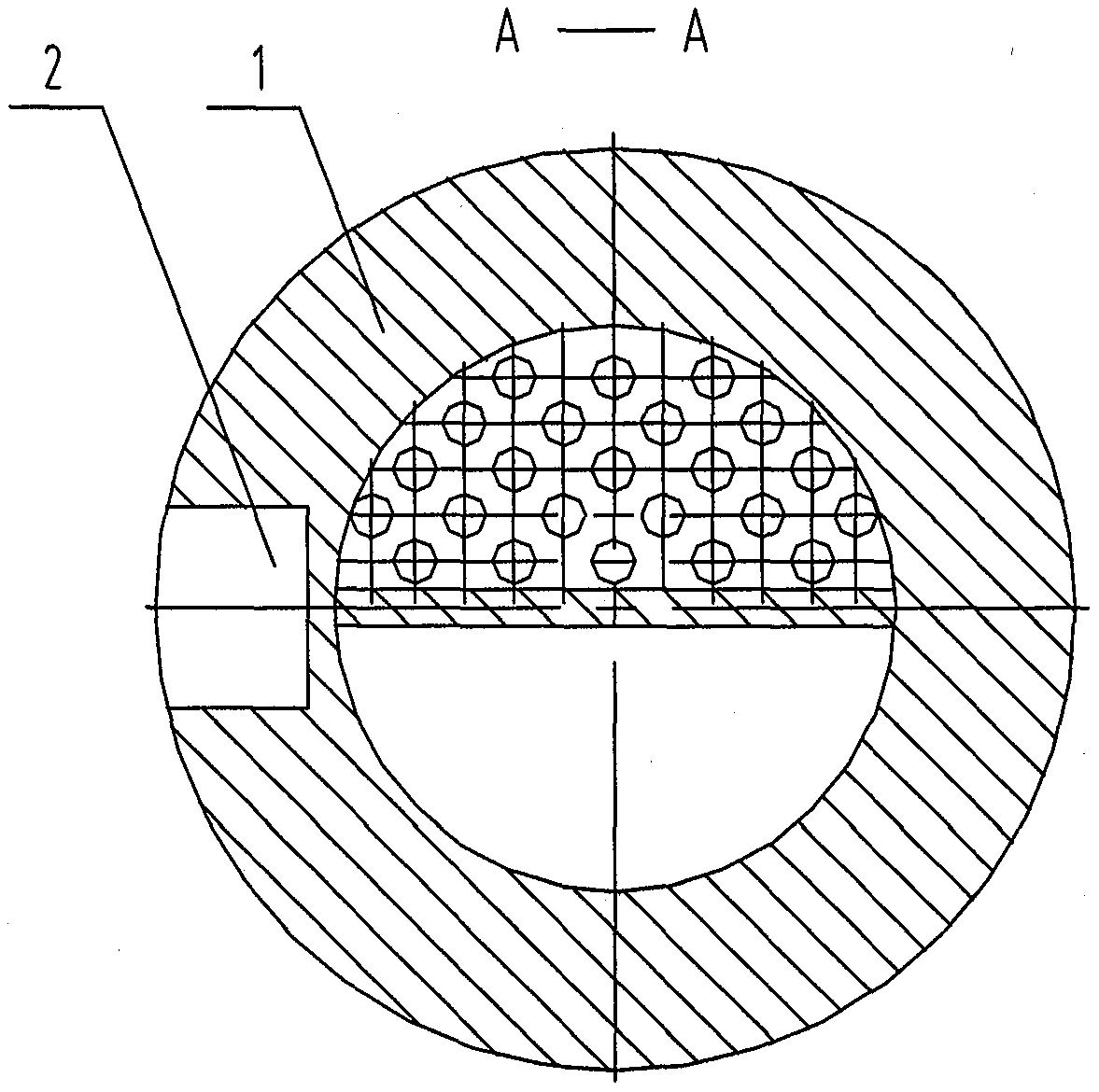

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention includes a spherical valve core body (1), a valve seat (3), an A-type throttle orifice (4), a B-type throttle orifice (5), a spherical adjustment pair (6), a circular channel (7) etc. The middle part of the spherical valve core body (1) is a circular channel (7), and one side of the channel is a small-hole spherical surface adjustment pair. In the circular channel of the valve core body, a piece of A-shaped throttle orifice is arranged along the direction of the flow channel. Type A throttling orifice is only processed with throttling holes in the lower half; one or more B-type throttling orifices are set in the upper space between the A-type throttling orifice and the circular channel, and no throttling holes are set in the lower space plate. Through the valve stem interface (2), the spherical valve core body (1) is connected with the valve stem, and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com