A construction method for dry mixed paving of indoor floor panels

A construction method and indoor ground technology, applied in the processing of building materials, construction, building construction, etc., can solve problems such as long construction period, poor working environment, and increased floor load, so as to improve construction speed and accuracy, and improve The effect of living comfort and convenient shelving in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

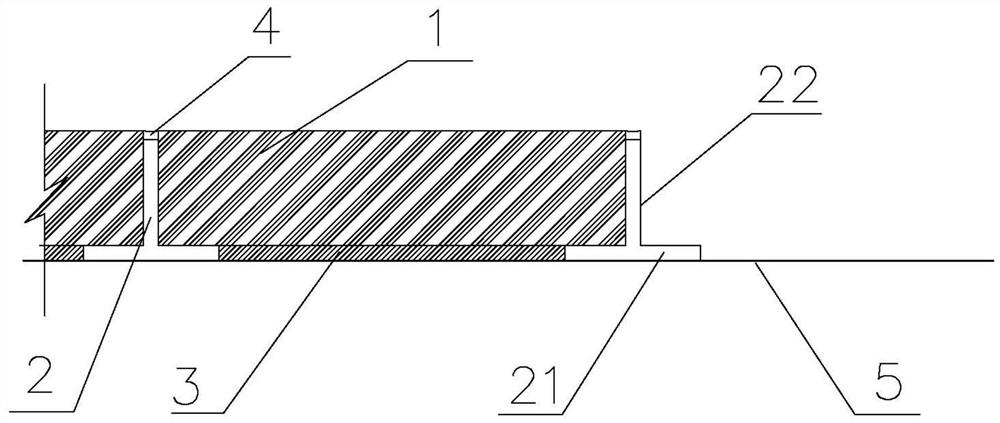

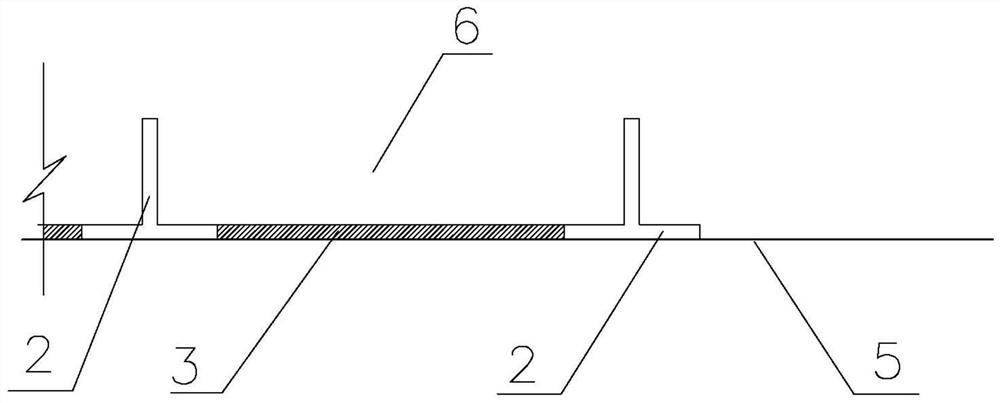

[0022] Please refer to the manual attached figure 1 and attached figure 2 As shown, the present invention is an indoor floor board dry-laid structure, which is laid on the floor 5 and consists of a floor board 1, a limit profile 2, a dry-laying base 3, and a gap glue 4.

[0023] Wherein, the limiting profile 2 is processed and assembled on the floor 5 according to the design requirements, and it is made of inverted "T" type metal material. The limiting profile 2 is composed of a horizontal flange plate 21 and a vertical partition plate 22 . The height of the partition plate 22 of the limiting profile 2 is 2-3 mm smaller than the thickness of the floor plate 1 .

[0024] Further, the dry laying base 3 material is laid in the limit section 6 enclosed by the limit section 2, and the scraper is placed on the limit section flange 21 opposite to the limit section 6 to scrape horizontally. , so that the dry-laying base 3 material accurately reaches its design elevation. The dry-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com