Preparation method of organic phosphor-supported hollow mesoporous SiO2 hydrophilic phosphorescent nanoprobe

A nanoprobe and organophosphorus technology, which is applied in the field of preparation of hollow mesoporous SiO2 hydrophilic phosphorescent nanoprobes loaded with organic phosphors, can solve the problems of insufficient removal of PS template spheres and cumbersome removal of PS template spheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

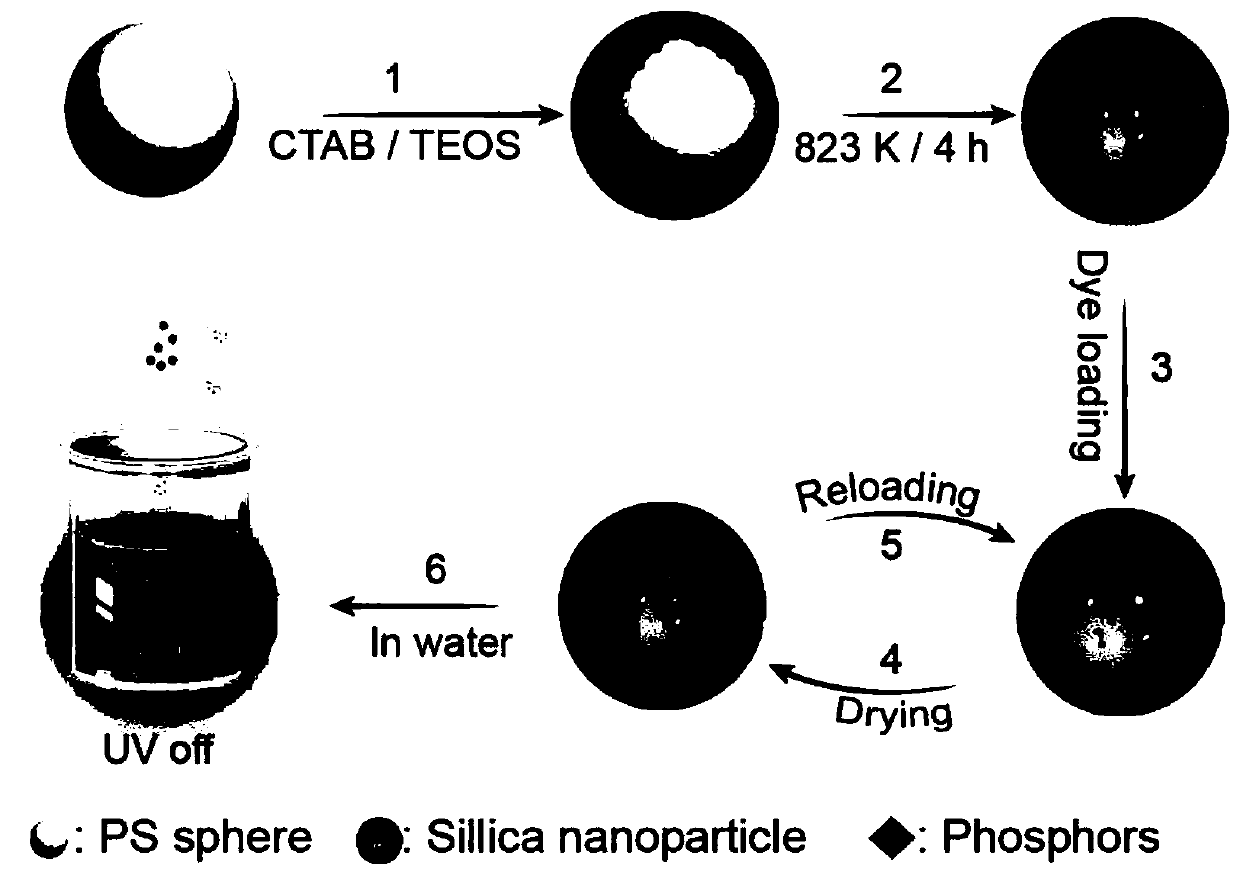

[0024] A Hollow Mesoporous SiO Loaded with Organic Phosphor 2 Hydrophilic phosphorescent nanoprobe preparation method, with reference to the specific route as figure 1 Shown:

[0025] (1). First, the template sphere PS (50 mg) was added into the flask, and then the surfactant triethanolamine (TEOA, 40 mg) and the porogen CTAB (75 mg) were added. After the mixture was heated to 80°C, a certain amount of silicon source TEOS (100 μL) was added to grow a layer of mSiO on the surface of PS spheres. 2 .

[0026] (2). After the reaction was completed by calcination (723K) in a muffle furnace, the PS template spheres and CTAB were completely removed within a certain period of time (4h) to obtain HMSNPs.

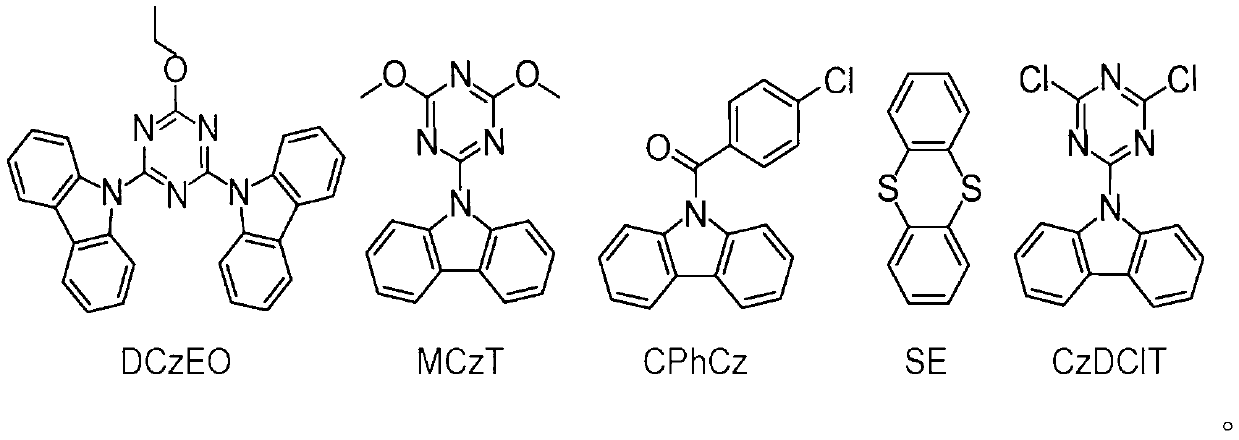

[0027] (3). Mix HMSNPs with a saturated solution (toluene) containing organic phosphor (DCzEO), and make the solution enter the cavity of HMSNPs.

[0028] (4). The HMSNPs filled with a saturated solution were dried (dried overnight at room temperature), so that the organic phosph...

Embodiment 2

[0030] A Hollow Mesoporous SiO Loaded with Organic Phosphor 2 Hydrophilic phosphorescent nanoprobe preparation method, with reference to the specific route as figure 1 Shown:

[0031] (1). First, the template sphere PS (50 mg) was added into the flask, and then the surfactant triethanolamine (TEOA, 40 mg) and the porogen CTAB (75 mg) were added. After the mixture was heated to 80°C, a certain amount of silicon source TEOS (200 μL) was added to grow a layer of mSiO on the surface of PS spheres. 2 .

[0032] (2). After the reaction was completed by calcination (823K) in a muffle furnace, the PS template spheres and CTAB were completely removed within a certain period of time (8h) to obtain HMSNPs.

[0033] (3). Mix HMSNPs with a saturated solution (dichloromethane) containing organic phosphor (MCzT), and make the solution enter the cavity of HMSNPs.

[0034] (4). The HMSNPs filled with a saturated solution were dried (dried overnight at room temperature), so that the organic...

Embodiment 3

[0036] A Hollow Mesoporous SiO Loaded with Organic Phosphor 2 Hydrophilic phosphorescent nanoprobe preparation method, with reference to the specific route as figure 1 Shown:

[0037] (1). First, the template sphere PS (100 mg) was added into the flask, and then the surfactant triethanolamine (TEOA, 80 mg) and the porogen CTAB (150 mg) were added. After the mixture was heated to 80°C, a certain amount of silicon source TEOS (200 μL) was added to grow a layer of mSiO on the surface of PS spheres. 2 .

[0038] (2). After the reaction is completed by calcination (823K) in a muffle furnace, the PS template spheres and CTAB are completely removed within a certain period of time (6h), thereby obtaining HMSNPs.

[0039] (3). Mix HMSNPs with a saturated solution (toluene) containing organic phosphor (CPhCz), and make the solution enter the cavity of HMSNPs.

[0040] (4). The HMSNPs filled with a saturated solution were dried (overnight under vacuum at room temperature), so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com