Electric power assisted braking system

A brake system and electric power assist technology, which is applied in the direction of brakes, brake transmission devices, transportation and packaging, etc., can solve the problems of too deep trampling, high cost, and high requirements for installation positions, so as to save costs and improve applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

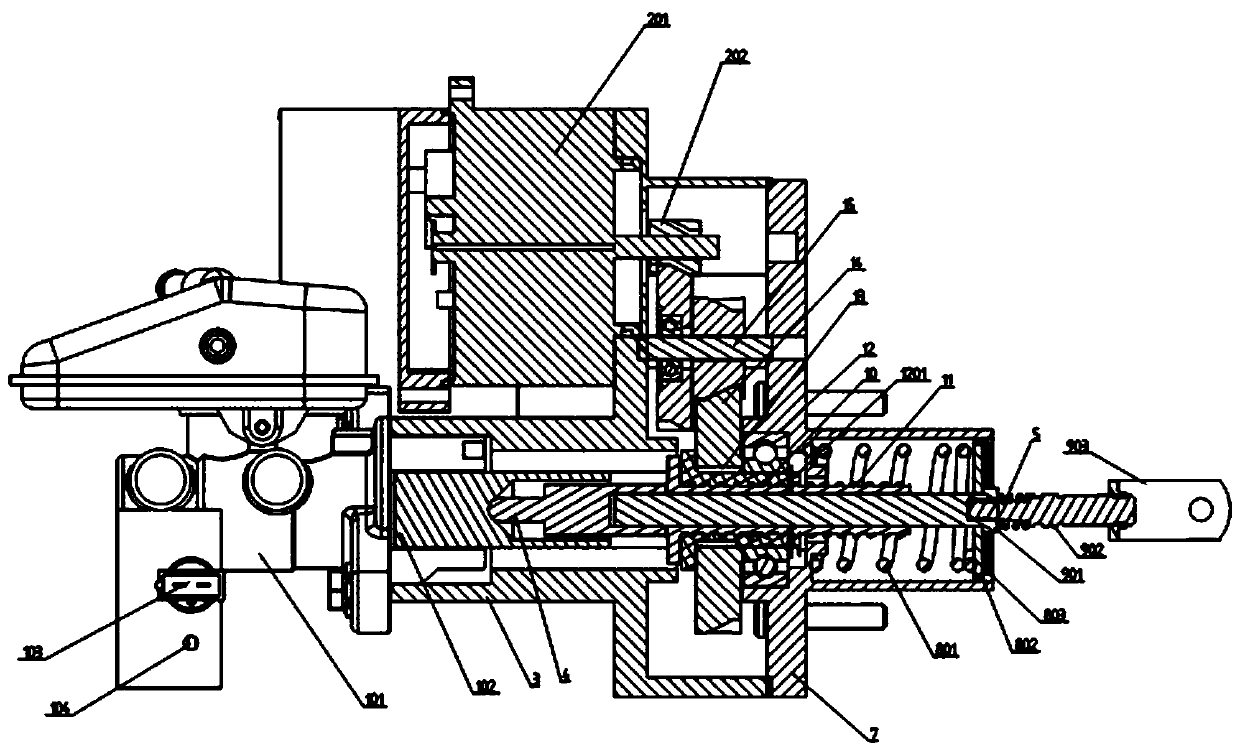

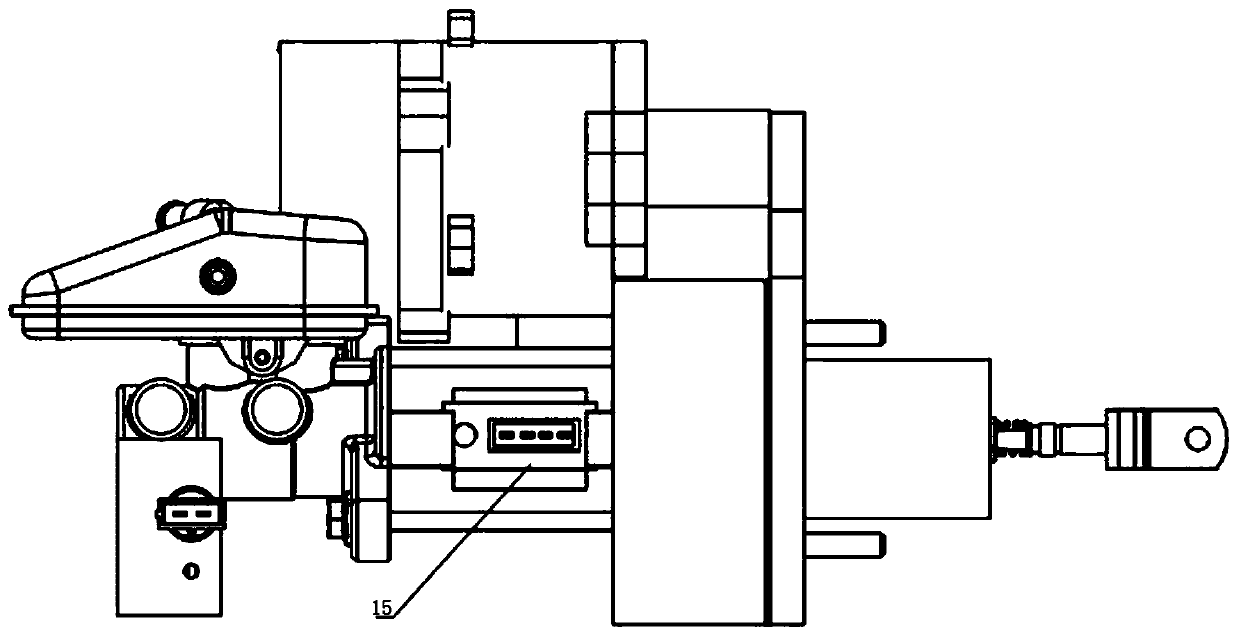

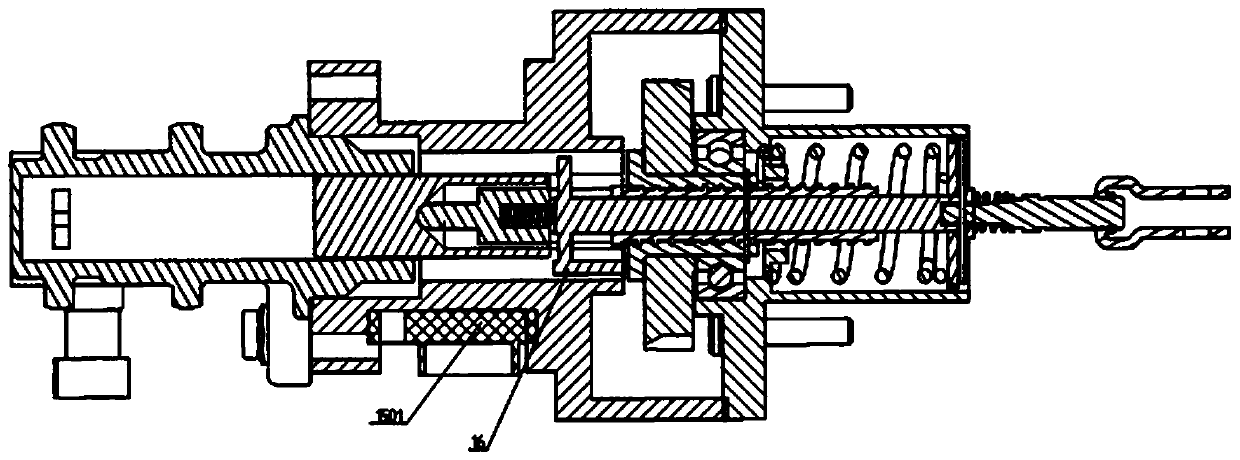

[0019] Example: As shown in the attached drawings, this electric power brake system mainly includes a master brake cylinder block 101, a master brake cylinder piston 102, a solenoid valve 103, a liquid storage chamber 104, a motor 201, a gear 202, a box Body 3, output rod 4, upper cover 7, push rod 901, input rod 902, shift fork 903, nut 10, screw rod 11, bearing 12, collar 1201, flat key 13, gear pair 14, sensor 15, sensor The chip 1501, the magnetic body 16, and the output shaft of the motor 201 are connected to the gear 202. The gear 202 transmits torque to the nut 10 through the gear pair 14. The gear pair 14 and the nut 10 are connected by a flat key 13. The nut 10 is installed on On the bearing 12 to realize positioning and rotation, one end of the nut 10 is limited by the clamp ring 1201, and the nut 10 is matched with the connecting screw 11 to convert the torque transmitted by the gear pair 14 into thrust and act on the output rod 4 at one end of the screw 11. , the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com