Any-modulus precast concrete beam forming device

A technology of precast concrete and modulus, which is applied in the direction of mold fixing devices, ceramic molding machines, molds, etc., which can solve the problems of not being able to form precast concrete beams of different modulus at the same time, low production efficiency, waste of materials, etc., and achieve convenient and quick demoulding , Improve production efficiency, and move stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

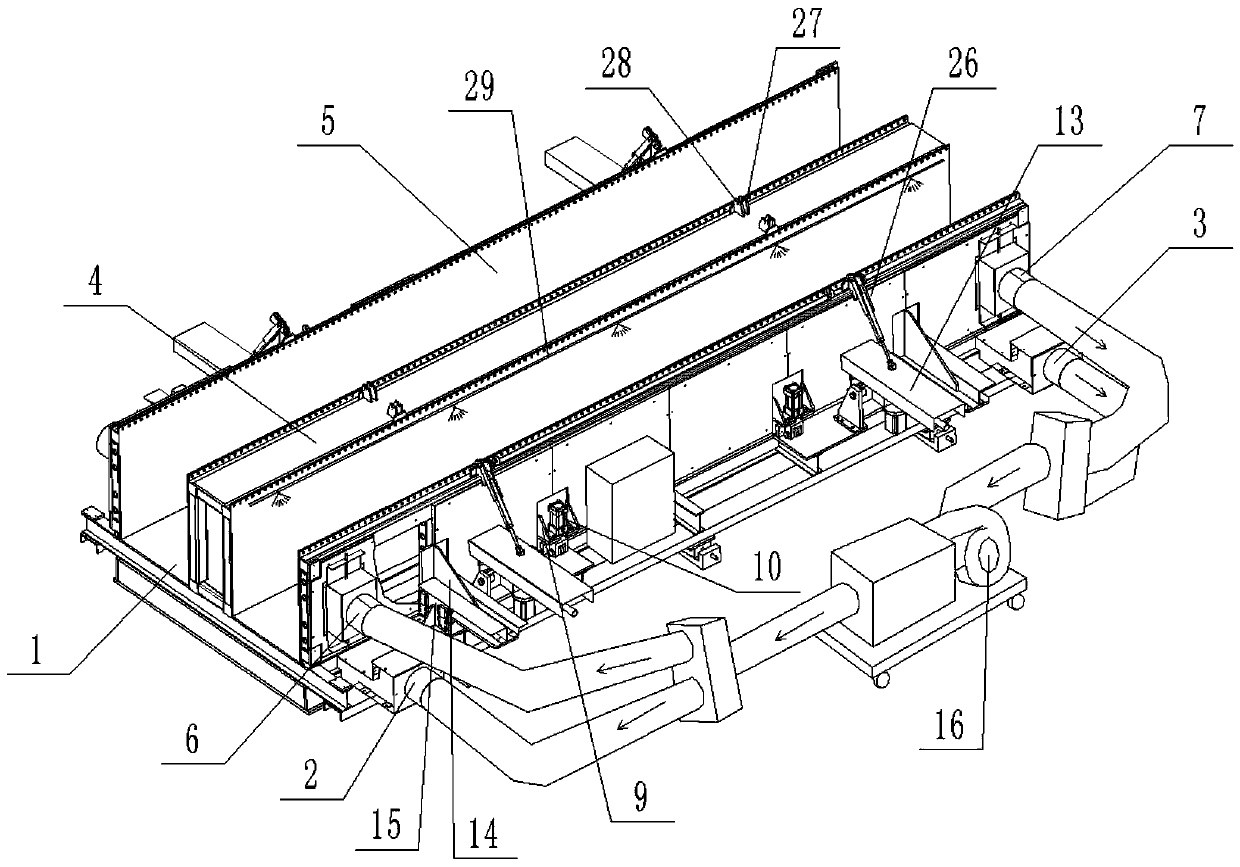

[0029] see Figure 1-3 The shown arbitrarily modulus precast concrete beam molding device includes: a bottom mold 1, which has a cavity, and the bottom mold 1 is connected with a first air inlet hole 2 and a first air outlet hole 3;

[0030] A certain mold 4, the top is fixed on the middle part of the bottom mold 1, the fixed mold 4 also has a cavity, and communicates with the cavity of the bottom mold 1;

[0031] Two side molds 5, the two side molds 5 are respectively located on both sides of the bottom mold 1, the side mold 5 has a cavity, and the side mold 5 is connected with a second air inlet hole 6 and a second air outlet hole 7;

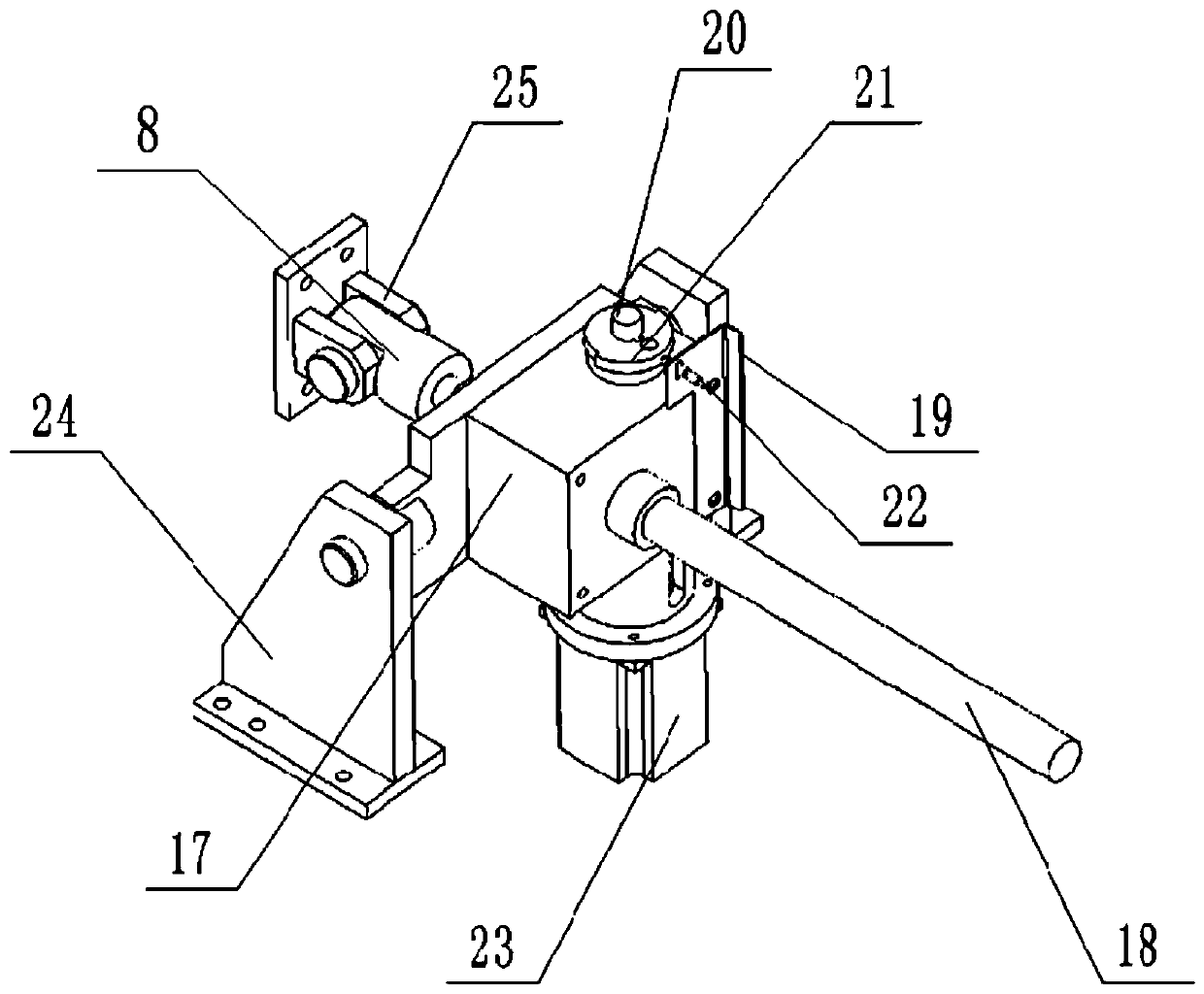

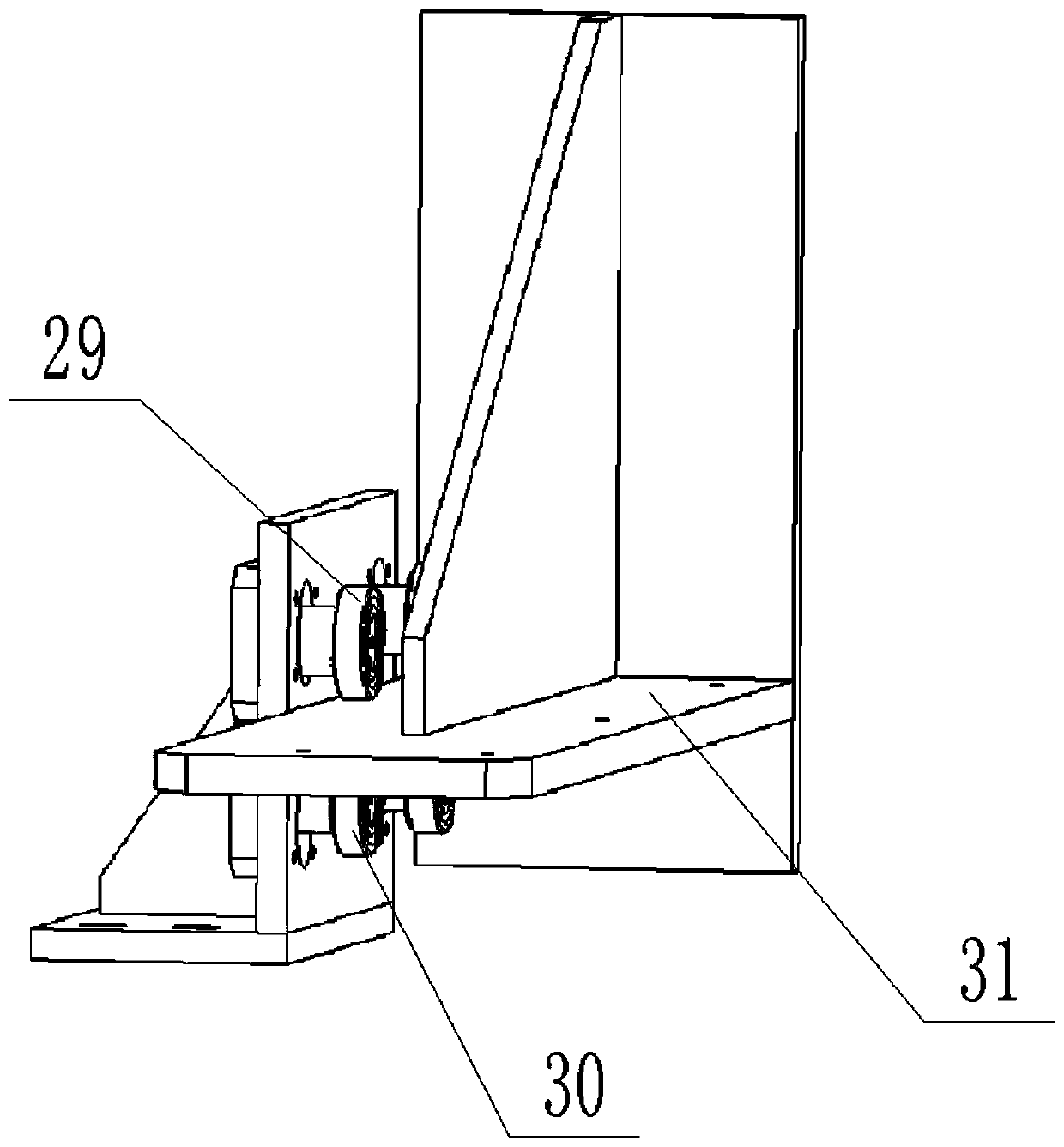

[0032] Side form translation device corresponding to side form 5, said side form 5 translation device includes several groups of translation drive assemblies and several lifting assemblies (determined quantity according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com