Clutch housing intelligent machining forming production line

A clutch housing, processing and forming technology, applied in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of high manual handling costs, complex drive structure, and bulky volume, etc., to achieve convenient control and high production efficiency , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

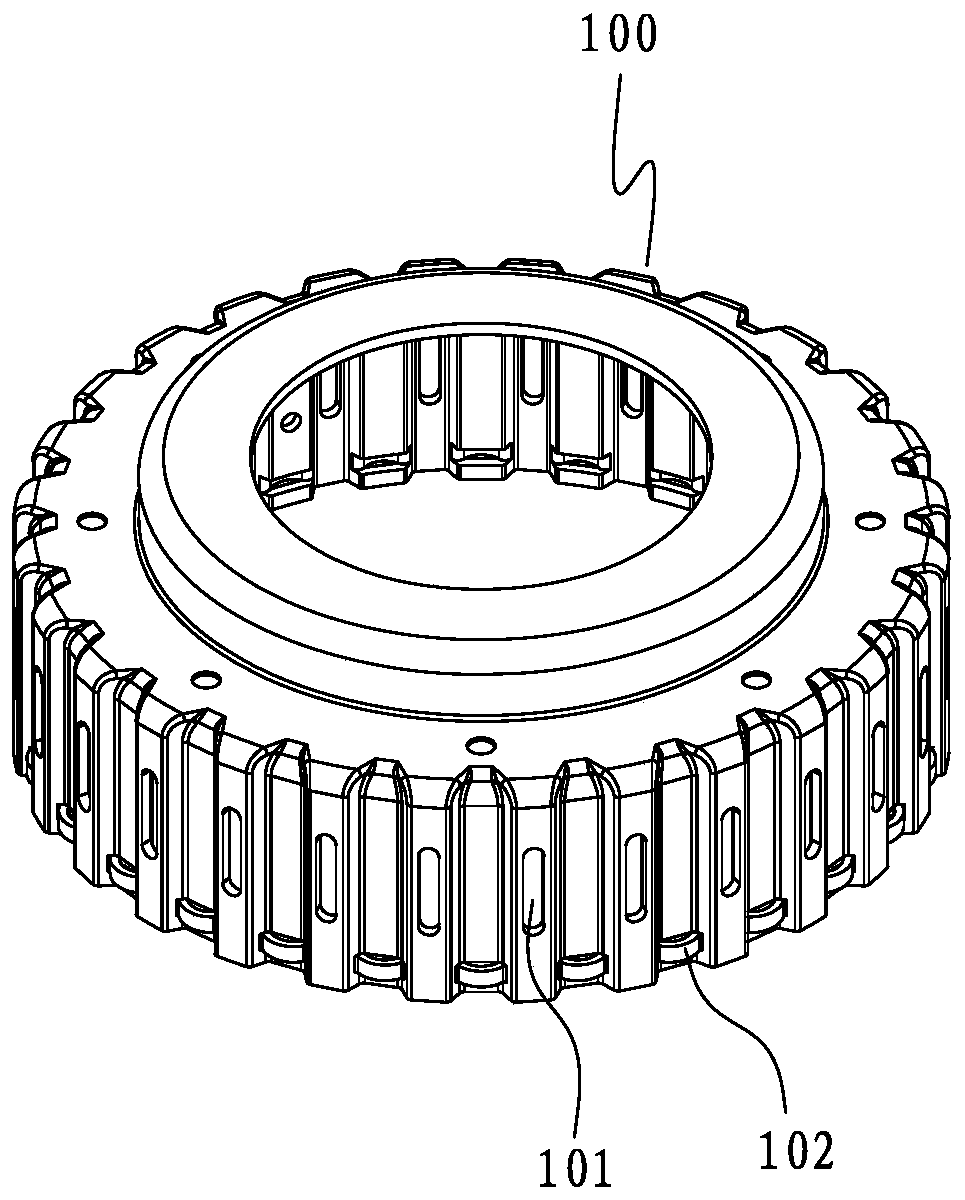

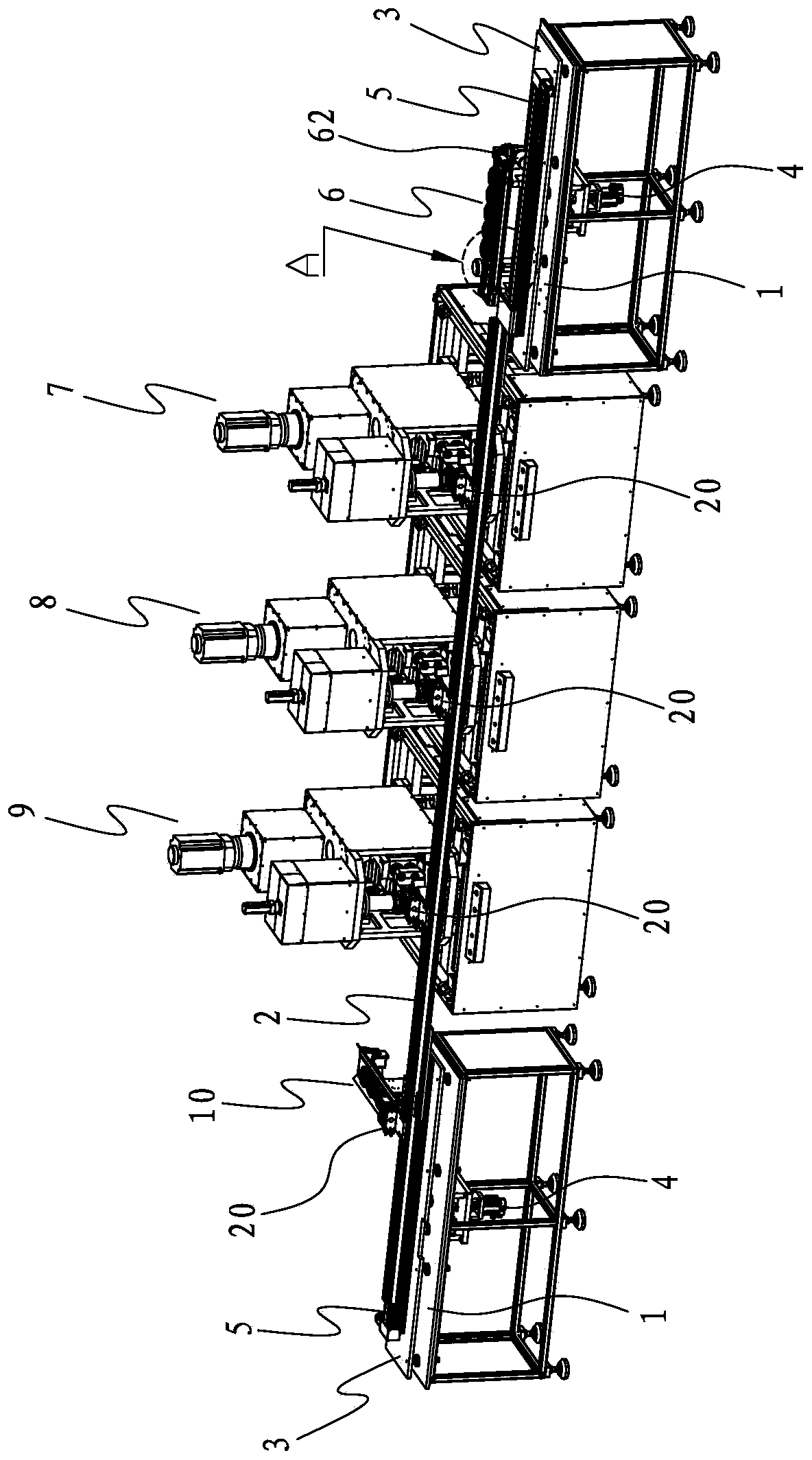

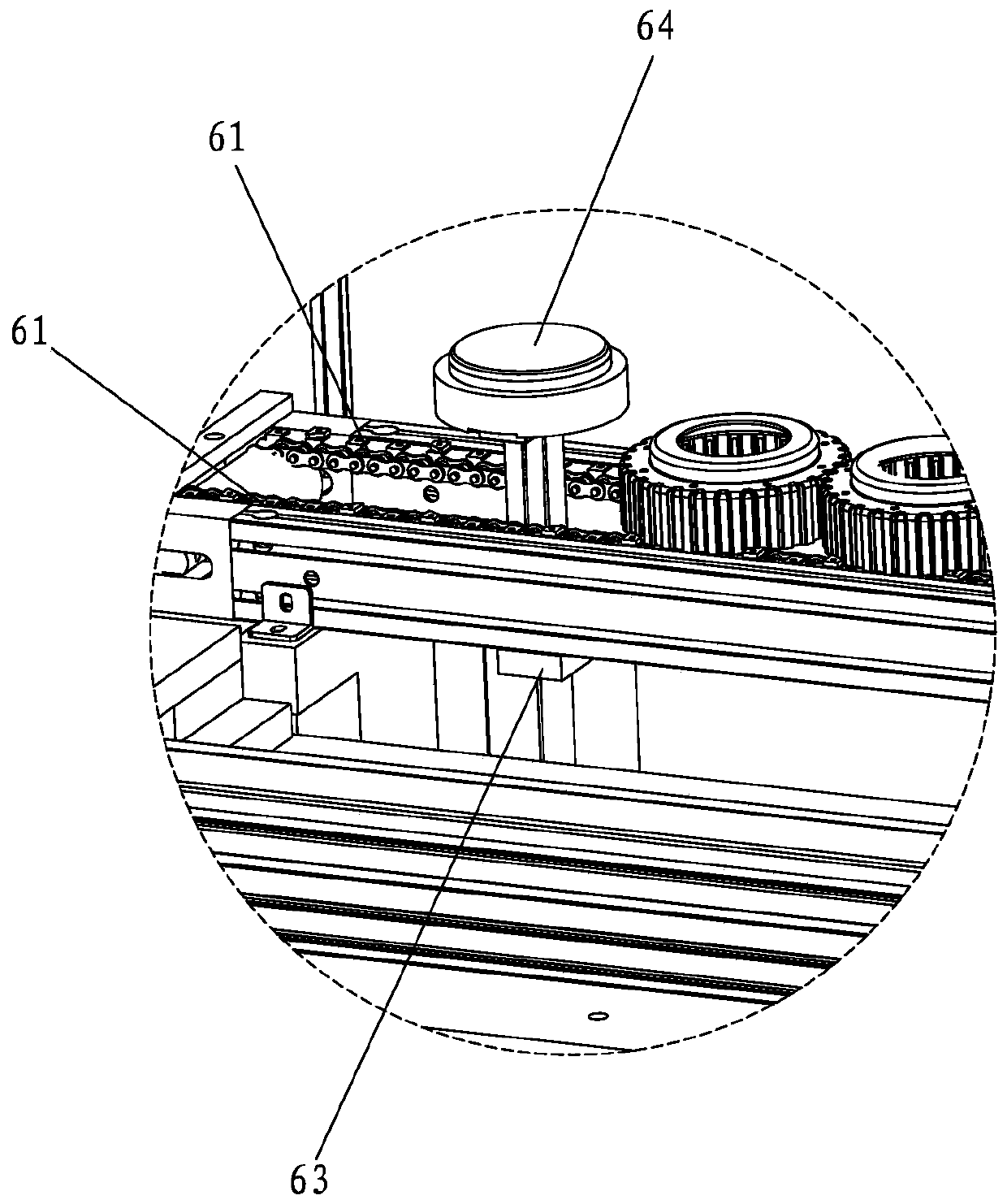

[0039] Such as Figure 2 to Figure 15 A production line for intelligently processing and forming clutch housings is shown, which includes two workbenches 1 separated on the left and right. Lifting plates 3 are slidably connected to the workbenches 1, and the bottom of the workbench 1 is provided with a The lifting cylinder 4 for lifting the plate 3, the feeding conveyor line 6 is provided on the right table 1, and the discharging conveyor line 10 is provided on the left table 1, and the distance between the two table 1 is from right to left A trimming device 7, a punching device 8 and a punching tongue device 9 are provided at intervals in sequence, the trimming device 7 is used for punching the bowl edge of the blank shell to a fixed length, and the punching device 8 is used for punching cooling holes 101, the punching tongue device 9 is used for punching and cutting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com