A kind of rolling cutting type thinning device for chemical raw material processing

A rolling cutting type, raw material technology, applied in the direction of chemical instruments and methods, solid separation, grain processing, etc., can solve the problems of direct falling, low degree of crushing and refinement of chemical raw materials, etc., and achieve the effect of avoiding clogging and fully uniform crushing of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

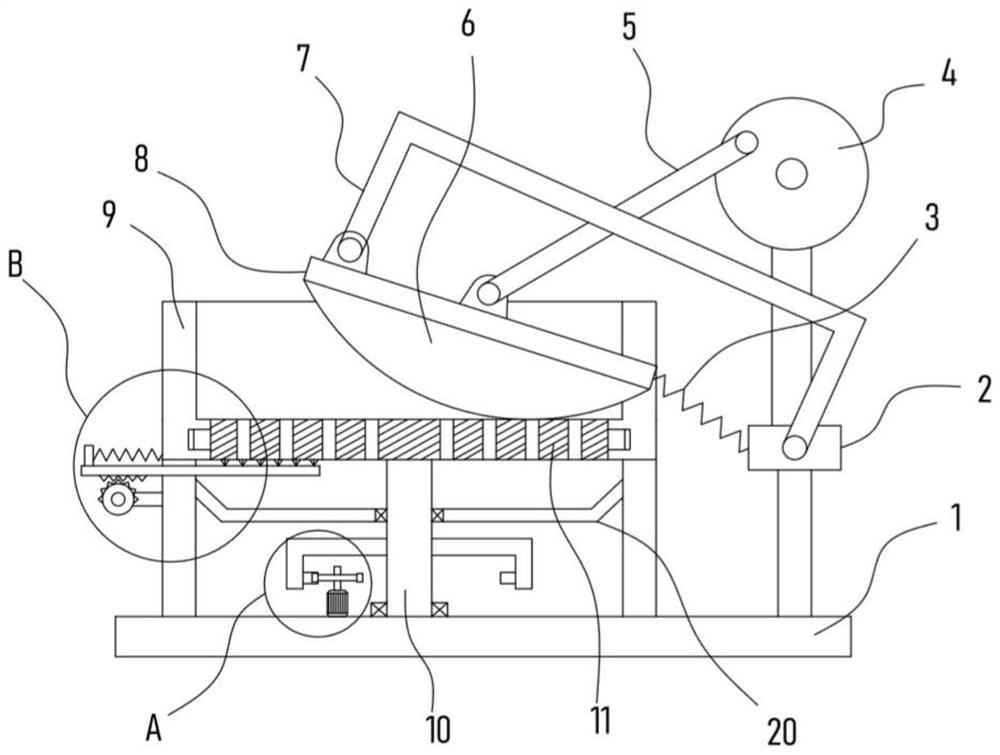

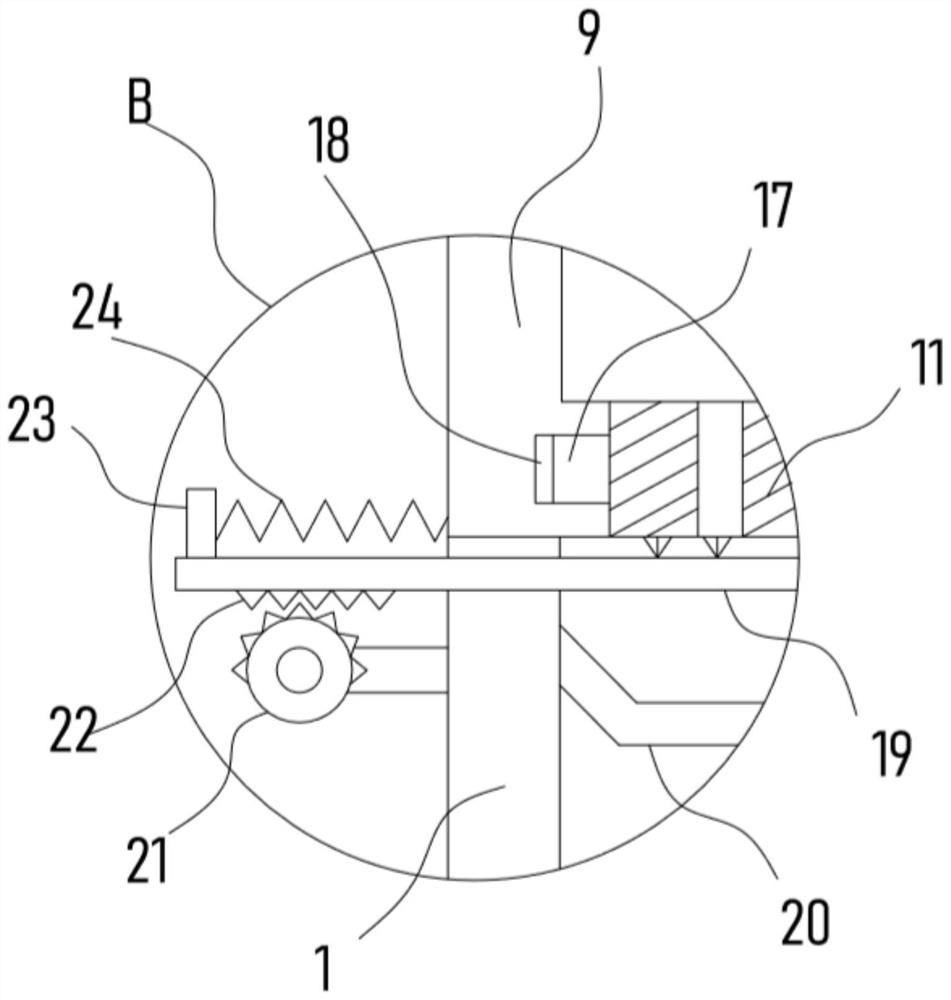

[0023] see Figure 1-5 , a chemical raw material processing roll-cutting refinement device, comprising a support frame 1, a surrounding barrel 9 is fixed on the supporting frame 1, a sieve plate 11 is installed in the surrounding barrel 9 through a rotating mechanism, and the side wall of the surrounding barrel 9 is vertical There is a chute 25, and the sieve tray 11 rolls against a thinning mechanism that runs through the chute 25. The bottom of the sieve tray 11 is provided with a collection tank 20, and the collection tank 20 is connected to the bottom of the sieve tray 11 through a reciprocating mechanism. The abutting brush plate 19.

[0024] When crushing and refining chemical raw materials, the chemical raw materials are placed in the enclosure 9 and finally fall on the sieve tray 11. The function of the sieve tray 11 is to allow the crushed and refined raw materials to pass through the sieve of the sieve tray 11. The holes fall into the collection tank 20 to ensure th...

Embodiment 2

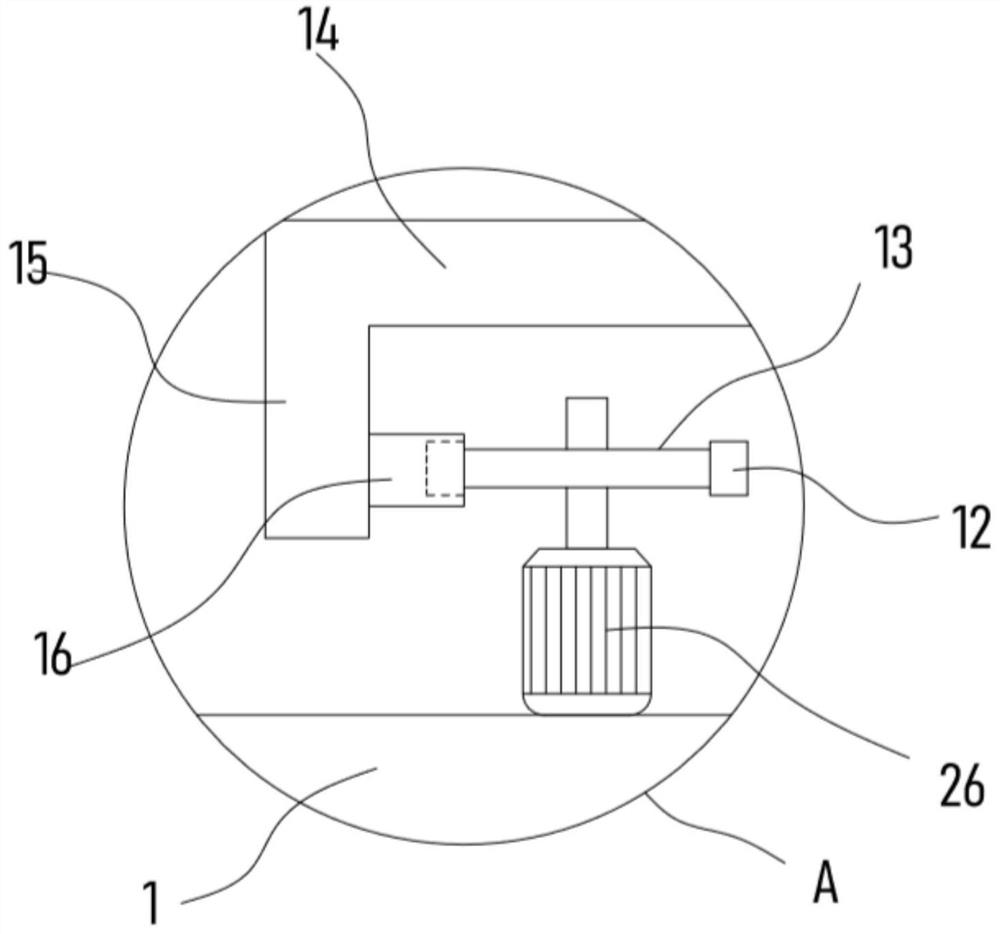

[0029] In order to enable the raw materials at different positions on the sieve tray 11 to be fully and comprehensively crushed and refined, on the basis of Embodiment 1, in addition, the output shaft on the drive motor 26 is fixed with a dial 13, and the bottom of the sieve tray 11 is fixed with a rotary Column 10, rotating column 10 is sleeved with and fixed with a turntable 14, the lower edge of the turntable 14 is circumferentially fixed with a coaming plate 15, the inner side wall of the coaming plate 15 is fixed with several transmission teeth 16 at equal intervals, and the end of the dial 13 is fixed with a transmission tooth. The tooth 16 is intermittently abutted against the shifting tooth 12 .

[0030] When the driving motor 26 is started, the driving motor 26 drives the dial 13 to rotate, and the dial 13 drives the dial 12 at the end to rotate and intermittently pushes the transmission teeth 16 on the shroud 15, so that the shroud 15 drives the turntable 14 together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com