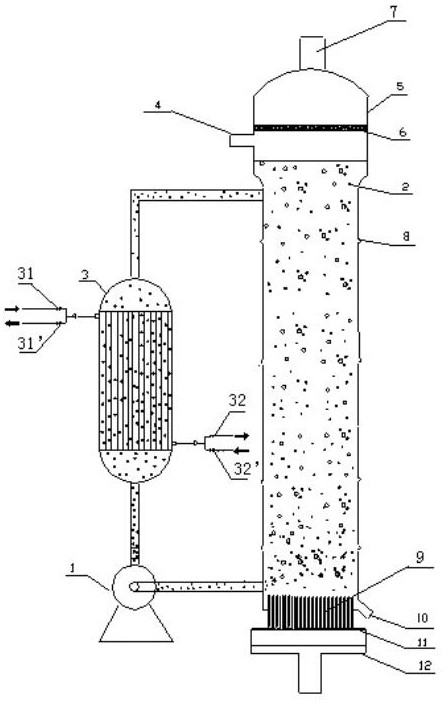

A three-phase flow reaction device for olefin hydroformylation and its operating method

A technology of olefin hydroformyl and reaction device, which is applied in the field of gas-liquid-solid three-phase circulating fluidized reactor and heat exchanger coupling device, can solve the problems of reactor overheating, catalyst decomposition, heat accumulation, etc. Achieve the effect of increasing the heat transfer coefficient and the total heat exchanger coefficient, reducing the content of by-products, and thinning the heat transfer boundary layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The inner diameter of the reactor is 600 mm, the height is 15 m, and the heat exchange area of the shell and tube heat exchanger is 18.4 m 2 In the three-phase flow hydroformylation reaction device, add n-butyraldehyde and a certain amount of rhodium phosphine complex catalyst and triphenylphosphine catalyst part, measure the concentration of palladium to be 50 mg / L, part triphenylphosphine The concentration is 2000 mg / L; then add spherical PTFE solid phase particles with a diameter of 3 mm, so that the solid content rate in the reactor is 4.0%; turn on the axial flow pump, the flow rate is 200 L / h, and the axial flow is adjusted by the frequency converter The rotation speed of the pump is 200~500 r / min; the heat exchanger 3 is heated with 120 °C low-pressure steam, and the temperature of the reactor is preheated to 85 °C; the synthesis gas (CO:H 2 The volume ratio is 1:1) 400 m 3 / h, nitrogen 50 m 3 / h, until the reaction pressure rises to 1.7 ~ 1.9MPa, open the fo...

Embodiment 2

[0048] The inner diameter of the reactor is 600 mm, the height is 15 m, and the heat exchange area of the shell and tube heat exchanger is 18.4 m 2 In the three-phase flow hydroformylation reaction device, add propionaldehyde and a certain amount of rhodium phosphine complex catalyst and triphenylphosphine catalyst part, measure the concentration of palladium to be 50 mg / L, the content of part triphenylphosphine The concentration is 2000 mg / L; add a certain amount of spherical polymelamine solid phase particles with a diameter of 4 mm, and the solid content rate in the reactor is 8.0%; turn on the axial flow pump, the flow rate is 800 L / h, and the axial flow rate is adjusted by the frequency converter. The rotation speed of the flow pump is 500~800 r / min; the heat exchanger 3 is heated with 120 °C low-pressure steam, and the temperature of the reactor is preheated to 85 °C; the synthesis gas (CO:H 2 The volume ratio is 1:1) 400 m 3 / h, nitrogen 50 m 3 / h, until the reactio...

Embodiment 3

[0050] The inner diameter of the reactor is 600 mm, the height is 15 m, and the heat exchange area of the shell and tube heat exchanger is 18.4 m 2 In the three-phase flow hydroformylation reaction device, add n-valeraldehyde and a certain amount of rhodium phosphine complex catalyst and triphenylphosphine catalyst part, measure the concentration of palladium to be 50 mg / L, part triphenylphosphine The concentration is 2000 mg / L; then add columnar polyvinyl chloride solid phase particles with a diameter (equivalent) of 8 mm, so that the solid content rate in the reactor is 15%; turn on the axial flow pump, the flow rate is 200L / h, and the frequency conversion Adjust the rotational speed of the axial flow pump to 100-200 r / min; heat the heat exchanger 3 with 120 °C low-pressure steam, and preheat the reactor temperature to 85 °C; feed synthesis gas (CO:H 2 The volume ratio is 1:1) 400 m 3 / h, nitrogen 50 m 3 / h, until the reaction pressure rises to 1.7 ~ 1.9 MPa, open the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com