Flexographic developers and methods of use

A flexographic plate and developer technology, applied in the field of relief images, can solve the problems of stamp printing defects, reduced solubility and the ability to form micelles, etc., and achieve the effect of environmental toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0240] A flexographic developer concentrate according to the invention is prepared by reacting a mixture of fatty acids with potassium hydroxide. The pH was adjusted to 10.6 and water was added to bring the solids concentration to 21 wt%. The final flexographic developer concentrate has the following components and amounts:

[0241] Palmitic acid 0.04% stearic acid 0.46% Oleic acid 15.77% Linoleic acid 1.24% Linolenic acid 0.02% Potassium hydroxide 3.48% water 79.00%

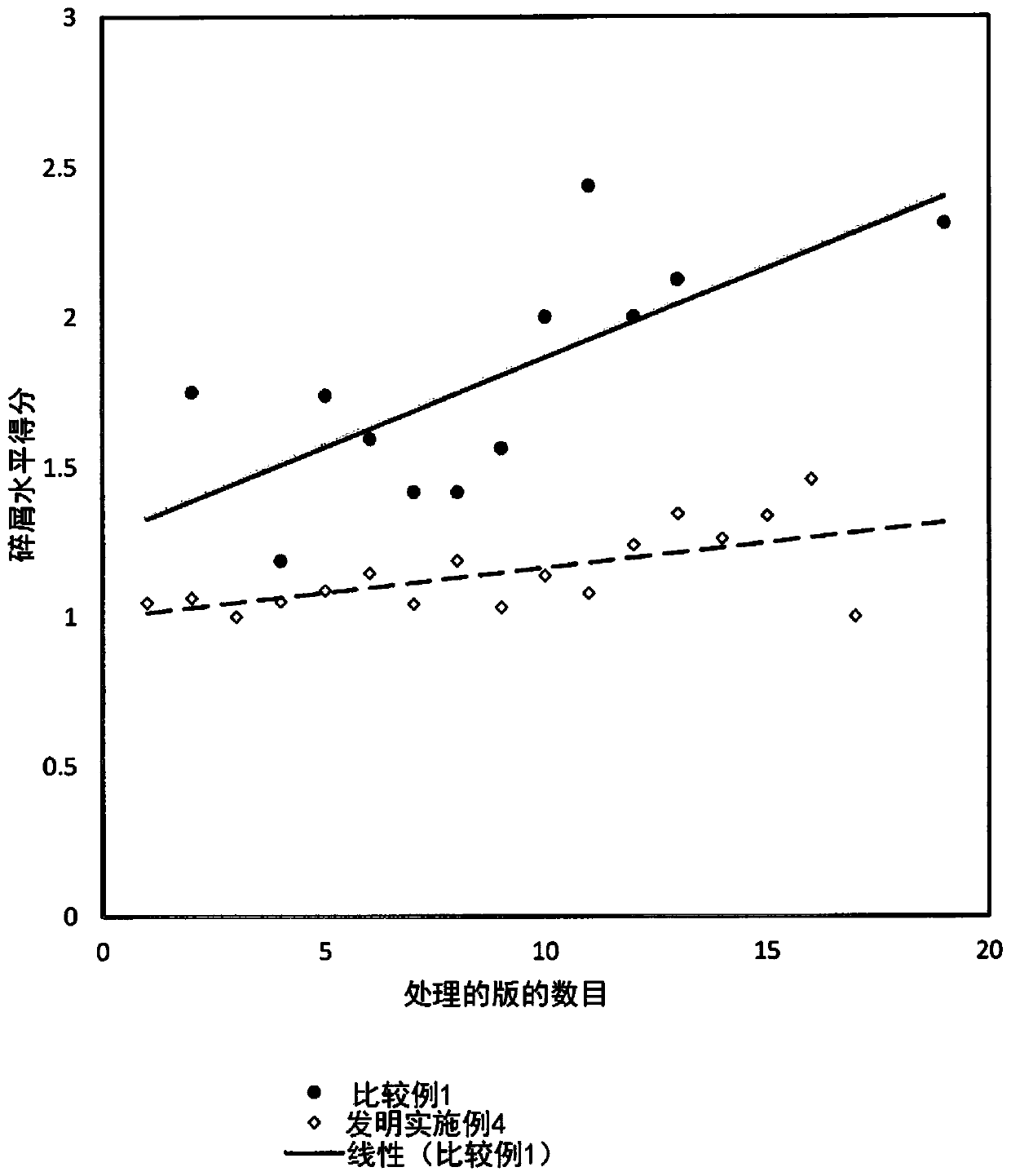

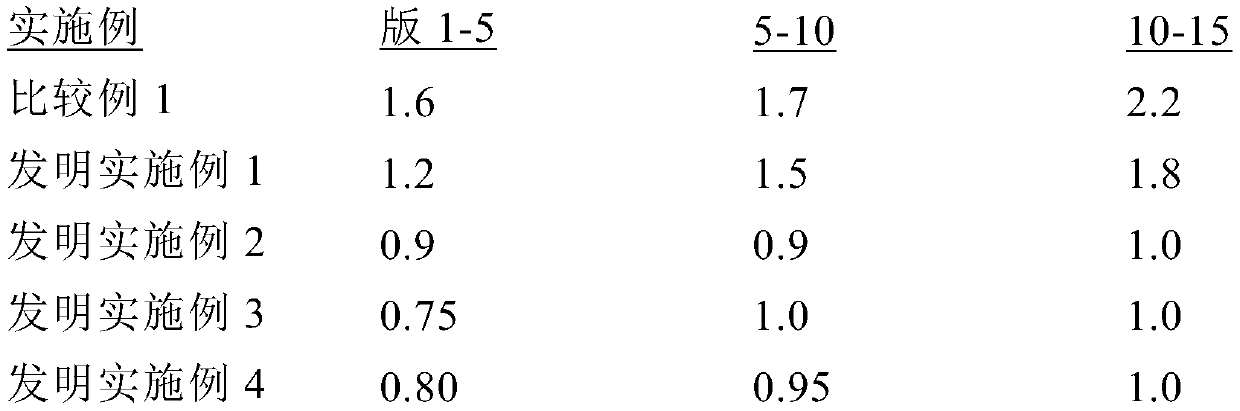

[0242] 1 part of this concentrate was diluted with 42 parts of water to provide an aqueous flexographic developer having a total fatty acid and fatty acid salt concentration of 0.5% by weight and a pH of 10.5. The resulting aqueous flexographic developer was placed in a track processor unit as described in Comparative Example 1 above and used to process the exposed flexographic printing plate. The amount of debris on the treated flexographic printing plates w...

Embodiment 2

[0243] A flexographic developer concentrate according to the invention is prepared by reacting a mixture of fatty acids with potassium hydroxide. Potassium carbonate was added and the pH was adjusted to 10.6. Water was added to bring the solids concentration to 21 wt%. The final flexographic developer concentrate has the following components and amounts:

[0244] Palmitic acid 0.03% stearic acid 0.33% Oleic acid 11.19% Linoleic acid 0.88% Linolenic acid 0.01% Potassium hydroxide 2.47% potassium carbonate 6.09% water 79.00%

[0245] 1 part of the resulting flexographic developer concentrate was diluted with 42 parts of water to provide an aqueous flexographic developer having a total fatty acid and fatty acid salt concentration of 0.5% by weight and a pH of 10.5.

[0246] As described in Comparative Example 1 above, an aqueous flexographic developer was placed in a track processor unit and used to process the exposed fl...

Embodiment 3

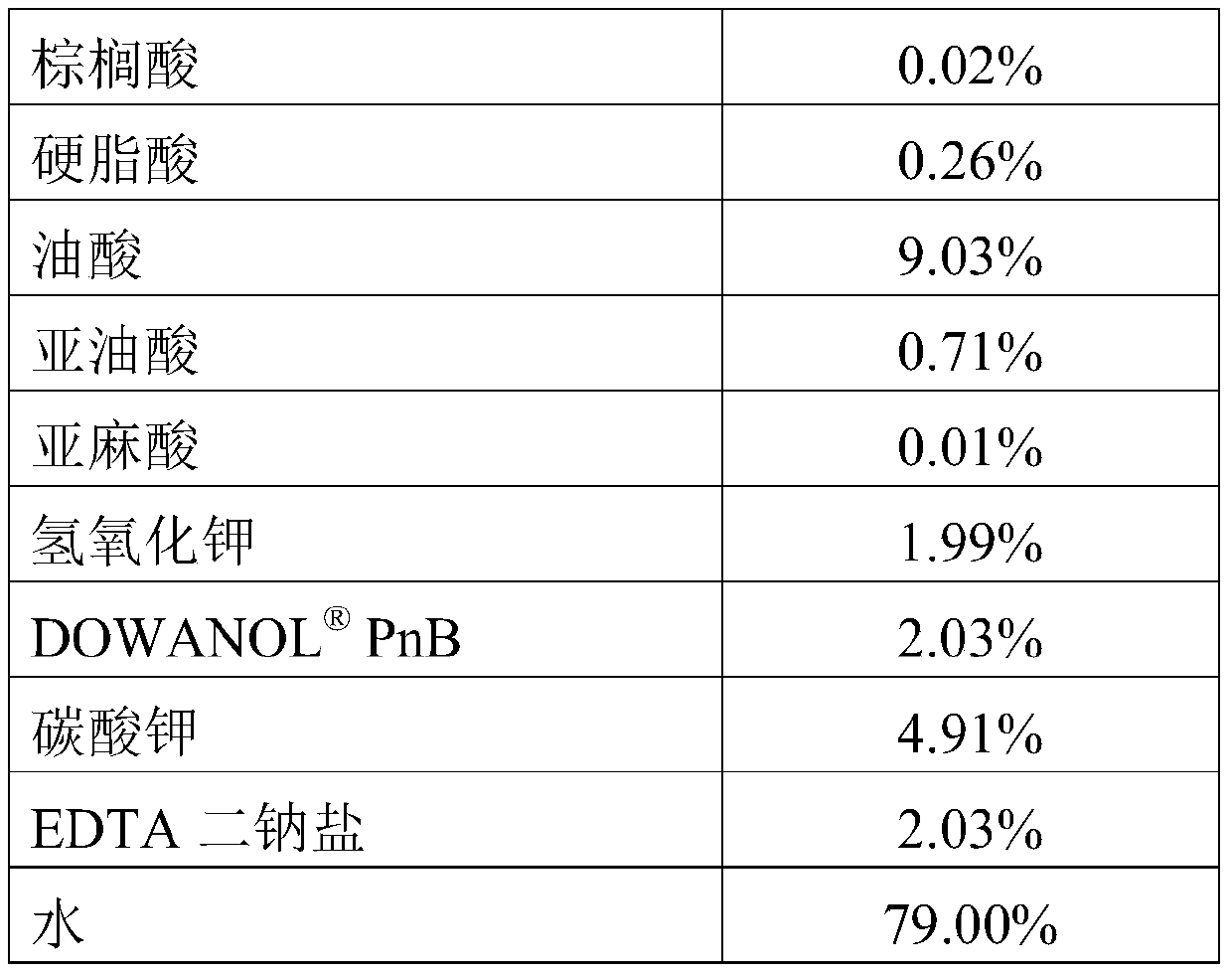

[0248] A flexographic developer concentrate according to the invention is prepared by reacting a mixture of fatty acids with potassium hydroxide. Potassium carbonate and EDTA disodium salt were added and the pH was adjusted to 10.6. Water was added to bring the solids concentration to 21 wt%. The final flexographic developer concentrate has the following components and amounts:

[0249] Palmitic acid 0.02% stearic acid 0.29% Oleic acid 10.00% Linoleic acid 0.79% Linolenic acid 0.01% Potassium hydroxide 2.21% potassium carbonate 5.44% EDTA disodium salt 2.25% water 79.00%

[0250] 1 part of the resulting flexographic developer concentrate was diluted with 42 parts of water to provide an aqueous flexographic developer having a total fatty acid and fatty acid salt concentration of 0.5% by weight and a pH of 10.5.

[0251] As described in Comparative Example 1 above, an aqueous flexographic developer was placed in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com