Self-learning-based on-line detection method for machine running faults in strong noise environment

A technology for machine operation and detection methods, applied in the field of online monitoring, can solve problems such as affecting the timeliness of fault monitoring, weak signal online detection defects, etc., and achieve the effect of stable online fault detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

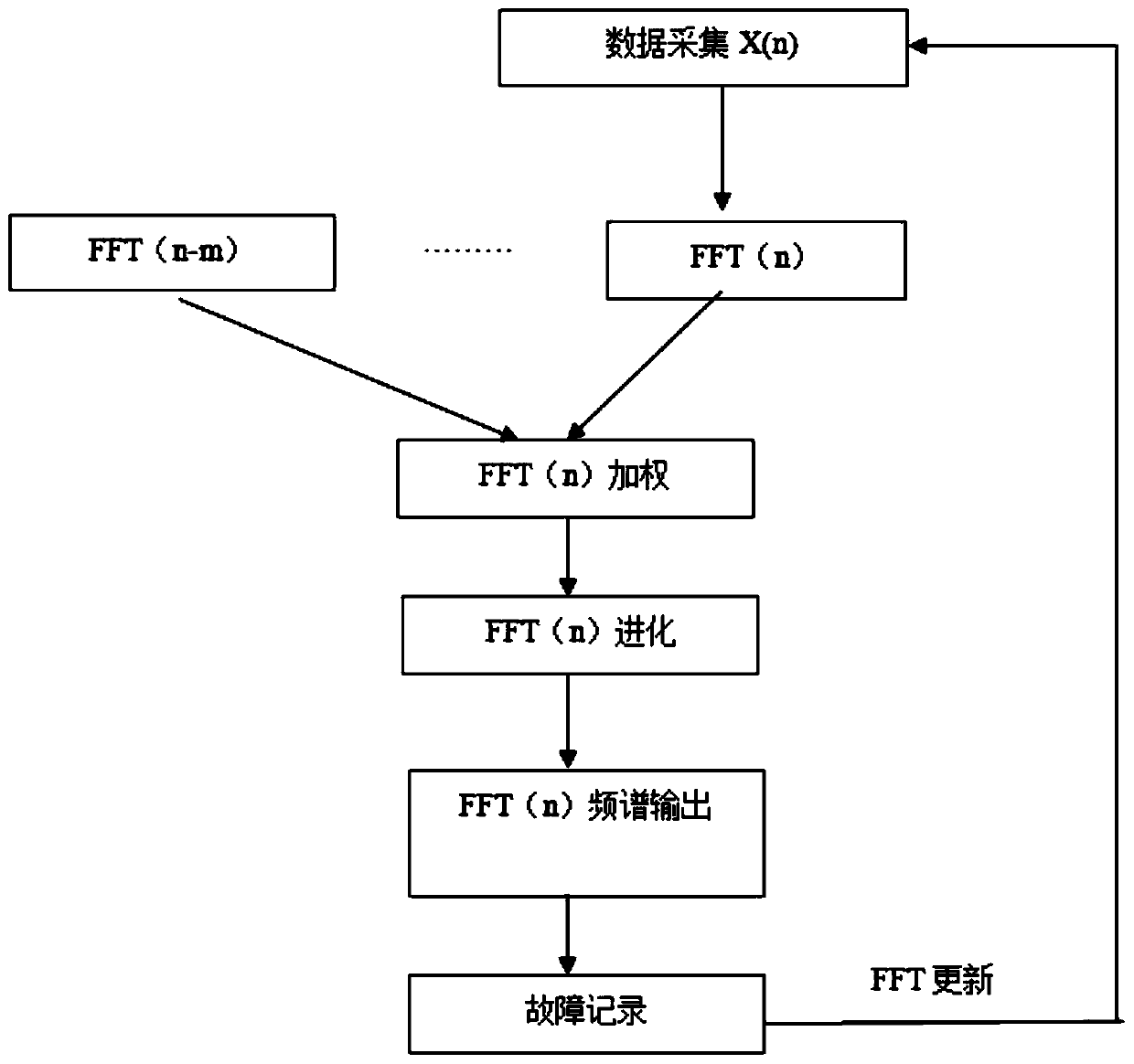

[0030] like figure 1 As shown, the present invention is based on a self-learning strong noise environment machine operation fault online detection method, characterized in that, the method comprises the following steps: S1: during the operation of the machine, collect the vibration signal generated during the operation of the machine, and The collected vibration signal is detected by the FFT algorithm; S2: after the vibration signal is collected for the nth time and the FFT spectrum detection is performed, the FFT(n) spectrum detection is weighted; S3: after the FFT(n) spectrum detection is weighted , optimize the signal spectrum through the nonlinear threshold evolution method, and suppress the noise generated by the machine operation; S4: output the FFT(n) spectrum after the nonlinear threshold is performed to the fault recording terminal, and record the fault data; S5 : After completing the fault record, update the FFT data and feed it back to the acquisition terminal when ...

Embodiment 2

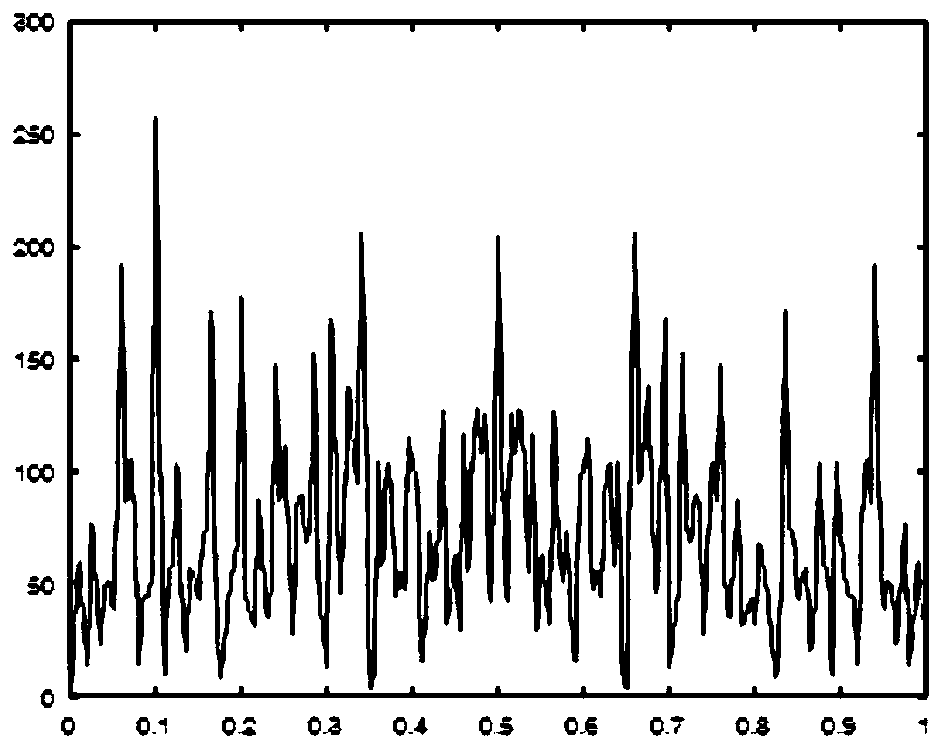

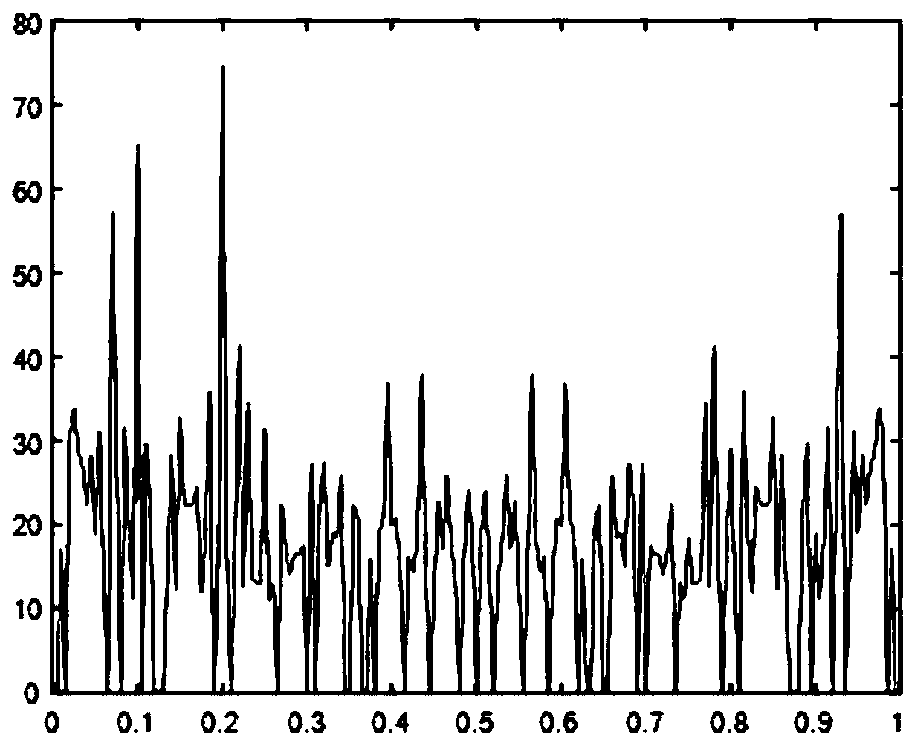

[0060] like Figure 2-5 As shown, this embodiment is specifically described on the basis of Embodiment 1, and compared through experiments, experiment: x(n)=exp(0.2πnj)+exp(0.4πnj)+exp(0.5πnj)*f( n)+w(n); Among them, the noise variance is 20, and the data window is 200.

[0061] pass figure 2 , 3 It can be seen that direct FFT analysis is almost impossible to detect machine fault signals online in a strong interference environment.

[0062] pass Figure 4 , 5 It can be seen that after the system is started, after a few cycles of self-learning, the system spectrum tends to be stable, and the natural vibration signal and fault signal of the system are clearly visible, which has a strong inhibitory effect on random noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com