Tire

A tire, tire circumferential technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., to improve mud performance, reduce pumping noise, and excellent mud performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

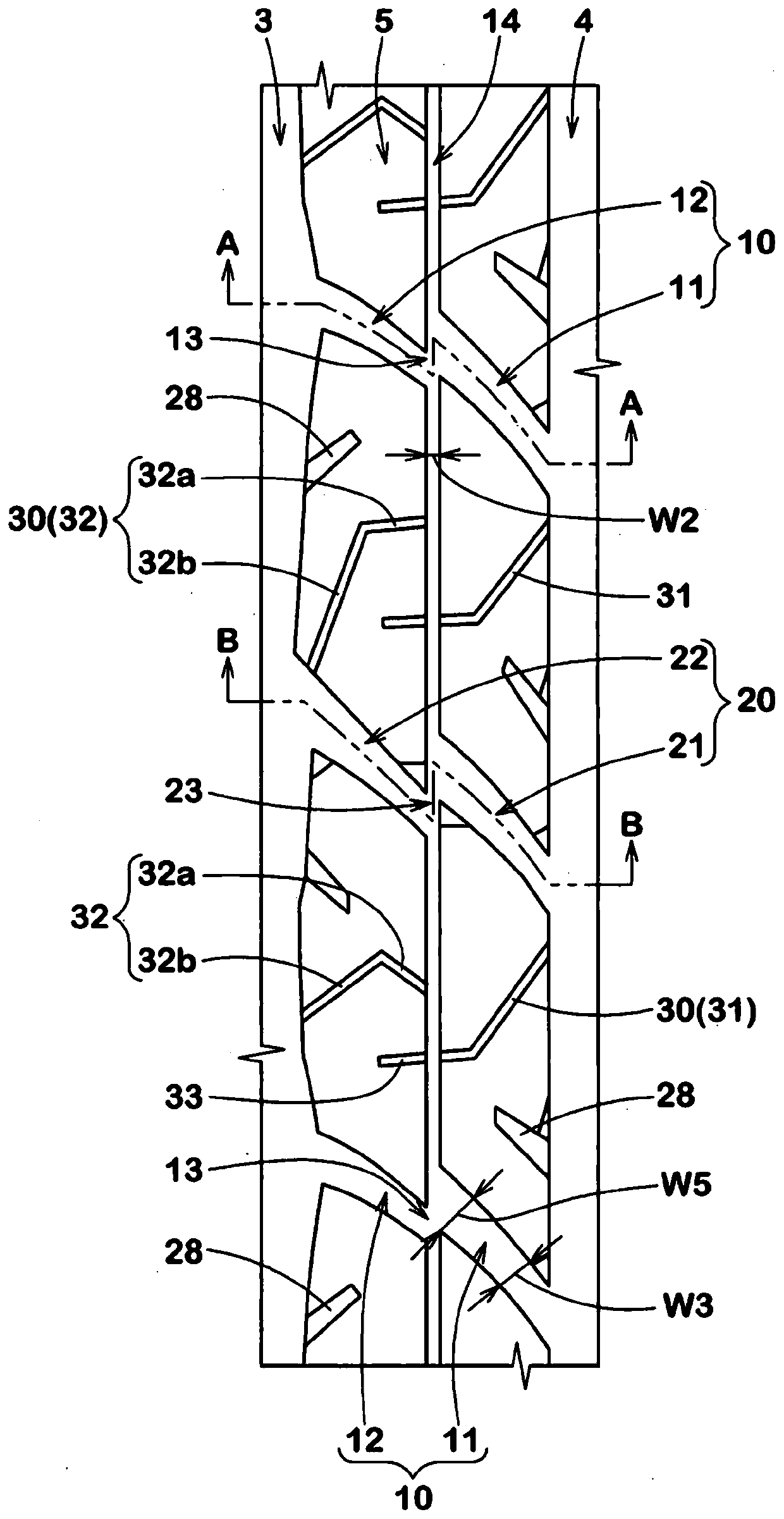

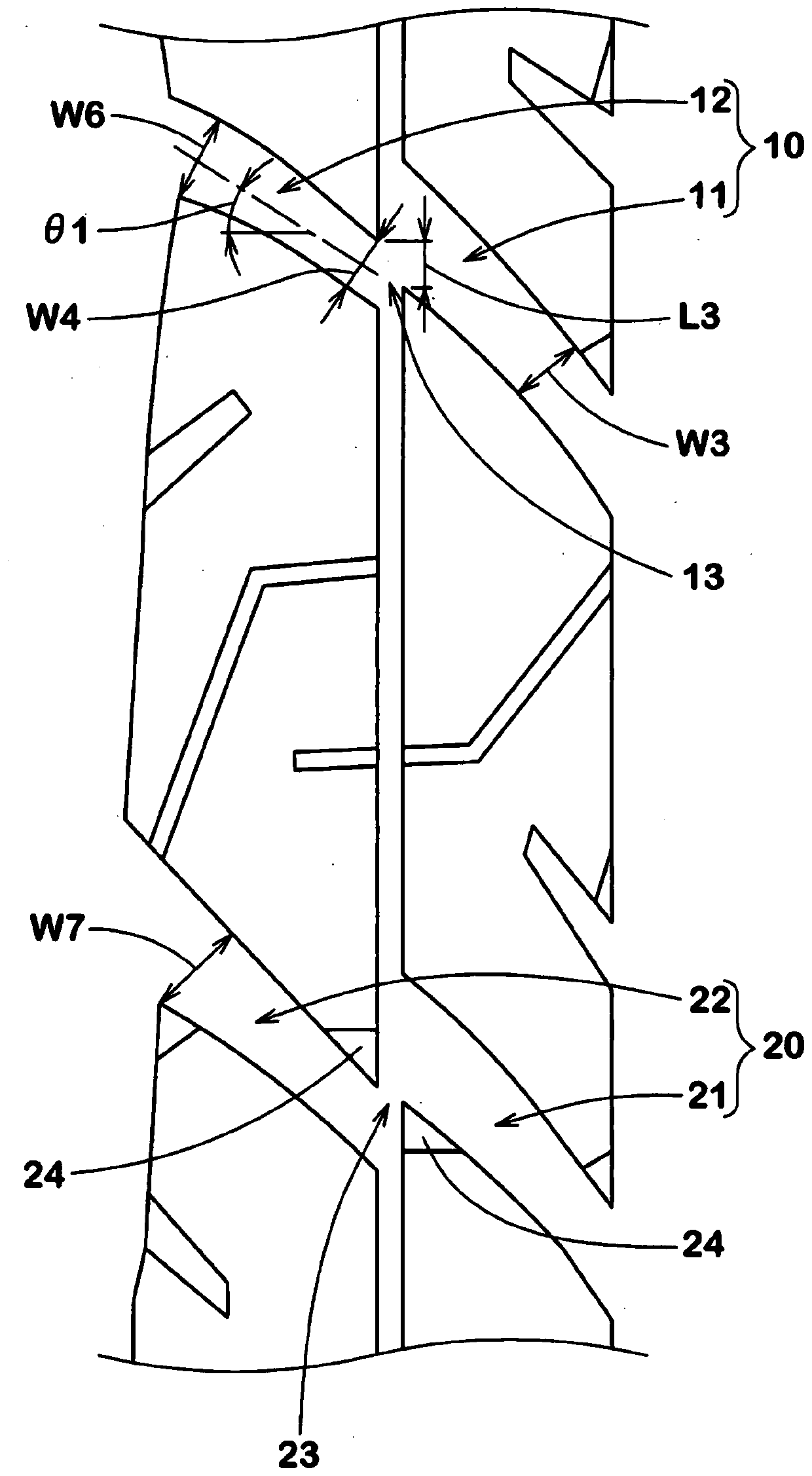

[0029] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

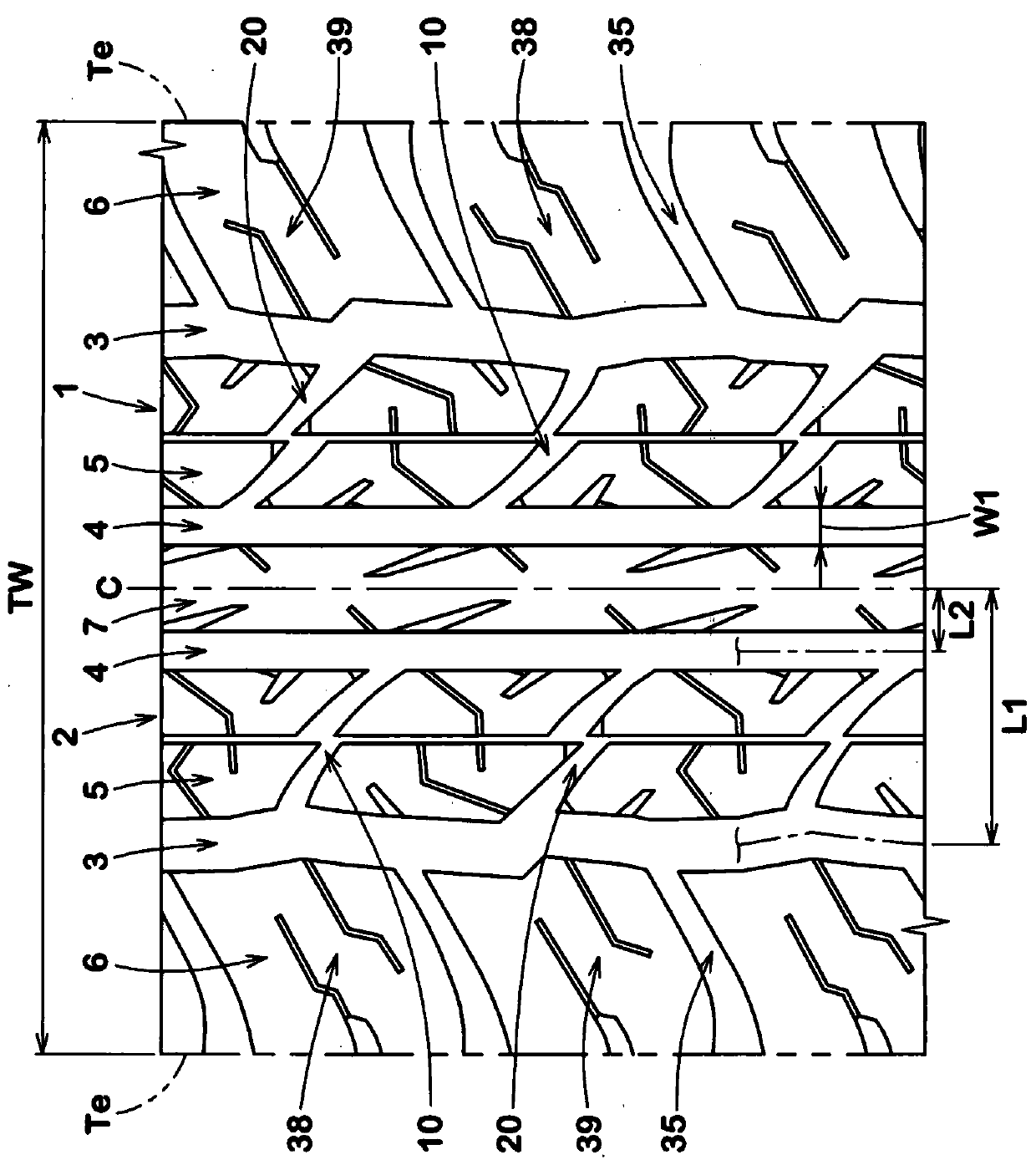

[0030] figure 1 It is a developed view of the tread portion 2 of the tire 1 of the present embodiment. The tire 1 of the present embodiment is used, for example, as a pneumatic tire for a passenger car, and is preferably used for an SUV that is predicated to travel on poor road surfaces. However, the tire 1 of the present invention is not limited to this embodiment.

[0031] Such as figure 1 As shown, the tread portion 2 is provided with a shoulder main groove 3 continuously extending in the tire circumferential direction on the tread edge Te side and a crown main groove 4 continuously extending in the tire circumferential direction on the tire equator C side.

[0032] The tread end Te means, in the case of a pneumatic tire, the tire axis when a normal load is applied to a normal tire 1 assembled on a normal rim and filled with a normal internal pressure in an unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com