Automatic nursery stock cuttage device

A seedling and automatic technology, applied in botany equipment and methods, horticulture, application, etc., can solve the problems of slow efficiency, waste of labor and labor costs, and achieve high efficiency, high degree of mechanization, saving labor and economic costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

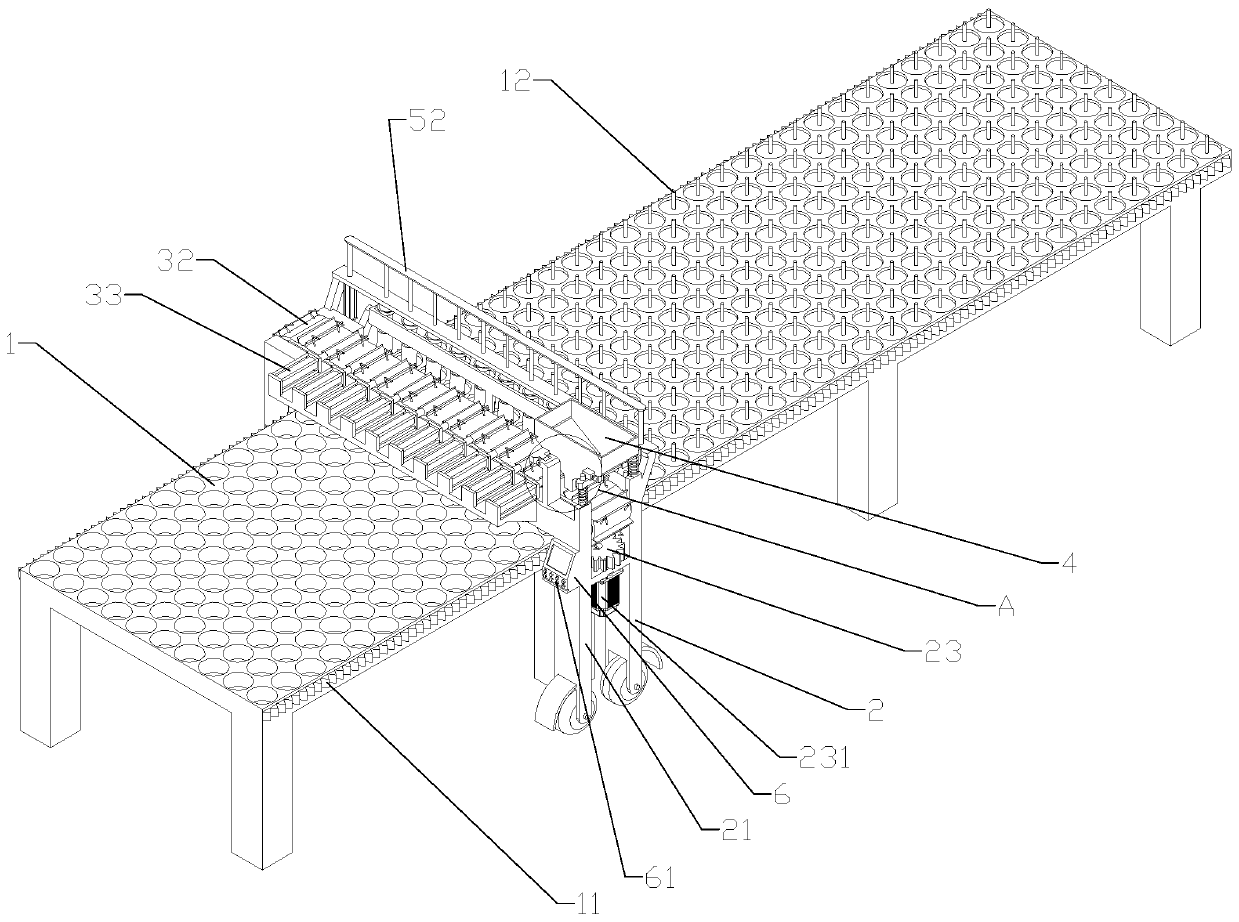

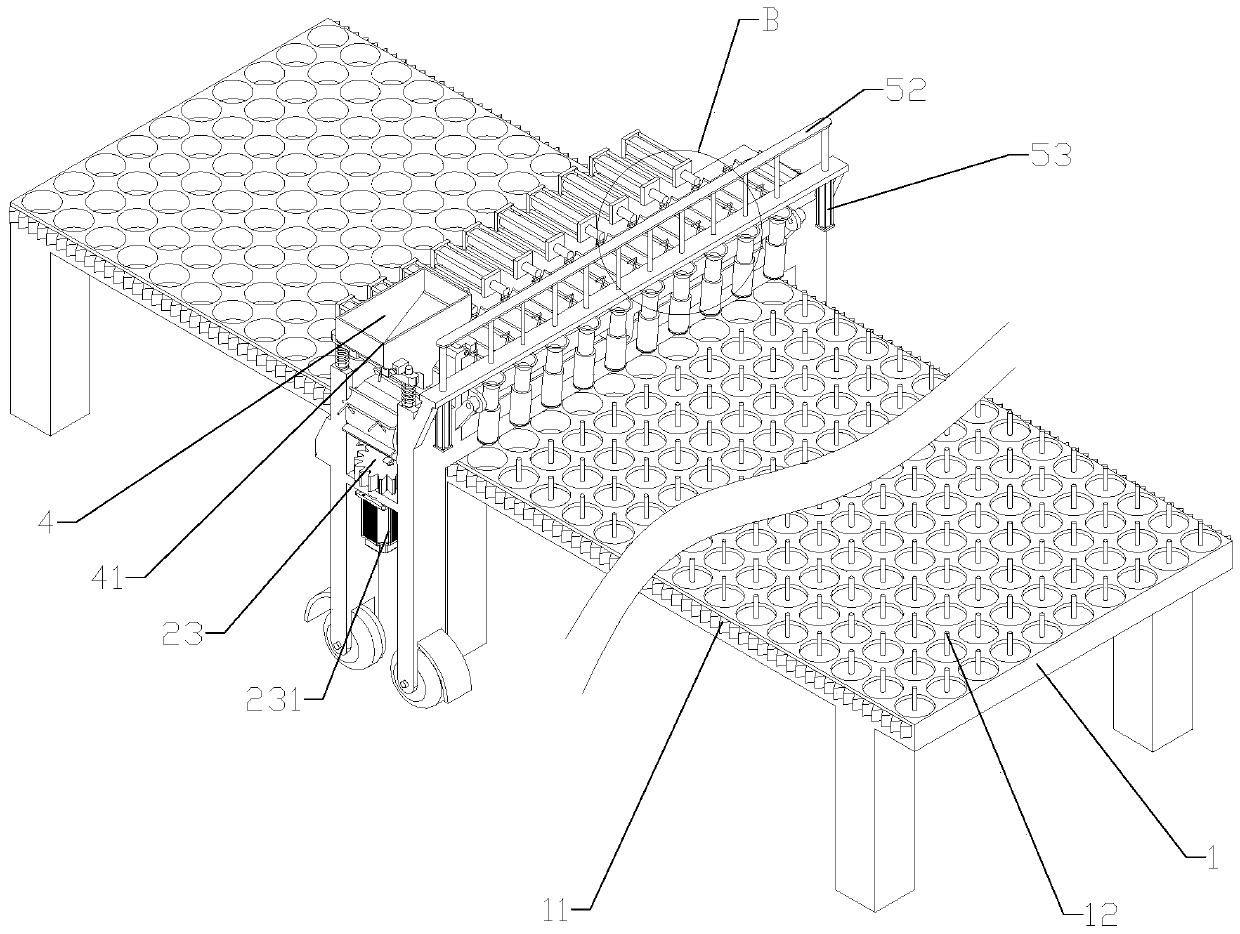

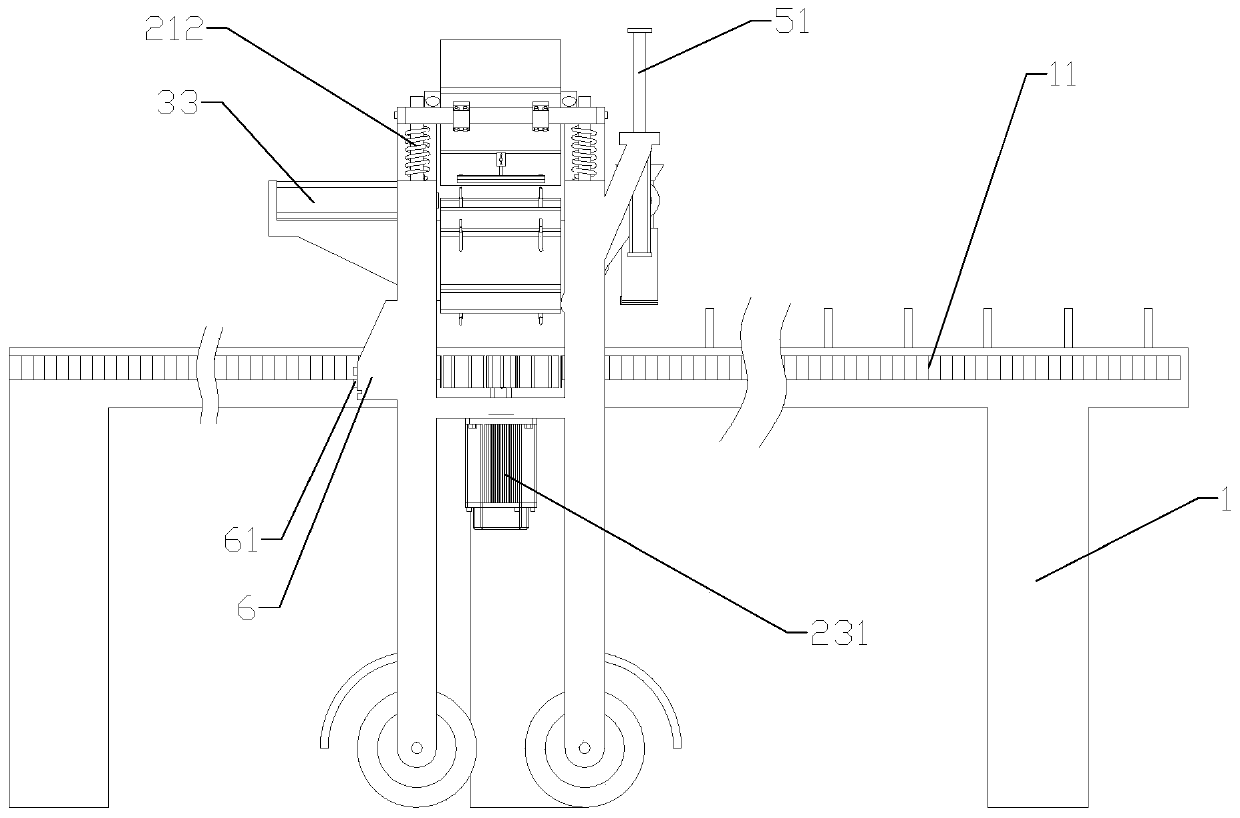

[0038] as attached figure 1 to attach Figure 18 As shown, the automatic cutting equipment for seedlings includes a movable car body 2 straddling the seedbed 1, a conveying mechanism 3 arranged on the car body 2, a feeding device 4 and a cutting device 5, and the car body 2 includes left and right sides Four support legs 21 arranged symmetrically and brackets 22 connecting adjacent support legs 21 . A rotatable gear 23 is set between the two legs 21 on each side, and the gear 23 meshes with the rack 11 provided on both sides of the seedbed 1, and the gear 23 is connected to a driving motor 231. The specific embodiment is: on the adjacent legs A horizontal plate is fixed between 21, the driving motor 231 is fixed on the bottom of the horizontal plate, and the output shaft of the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com