Radial loading device for thin-wall bearing vibration measurement

A technology of thin-walled bearings and loading devices, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., to achieve reliable loading force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

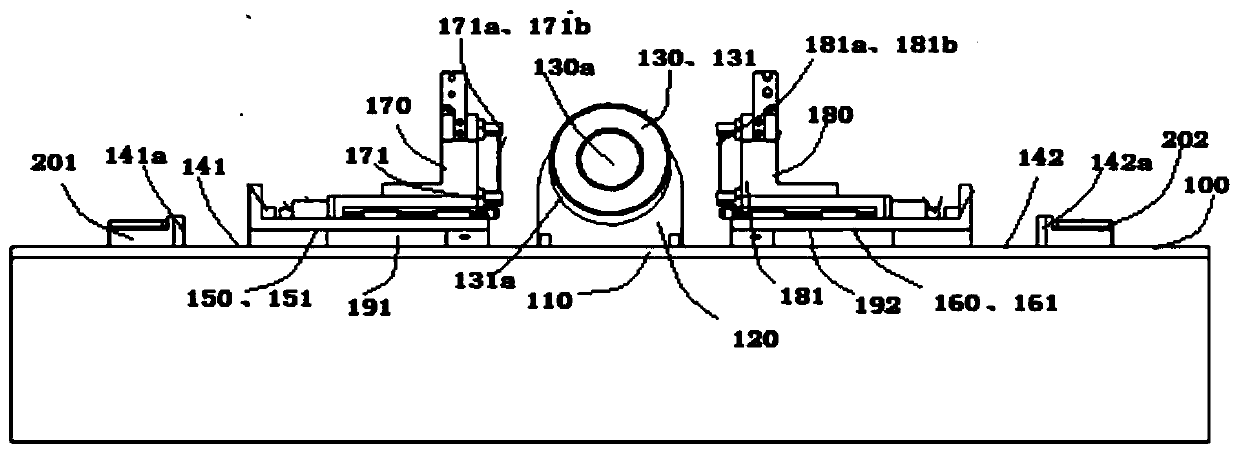

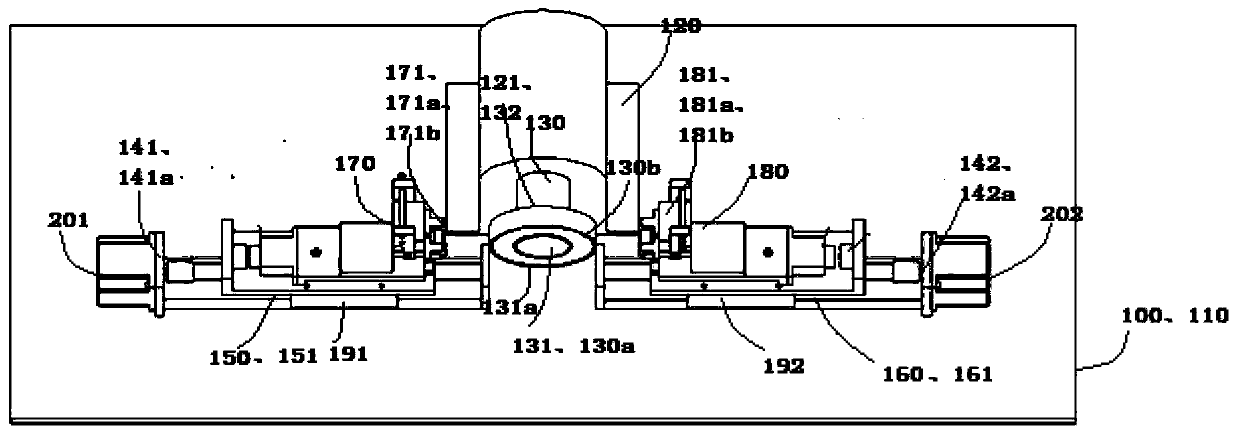

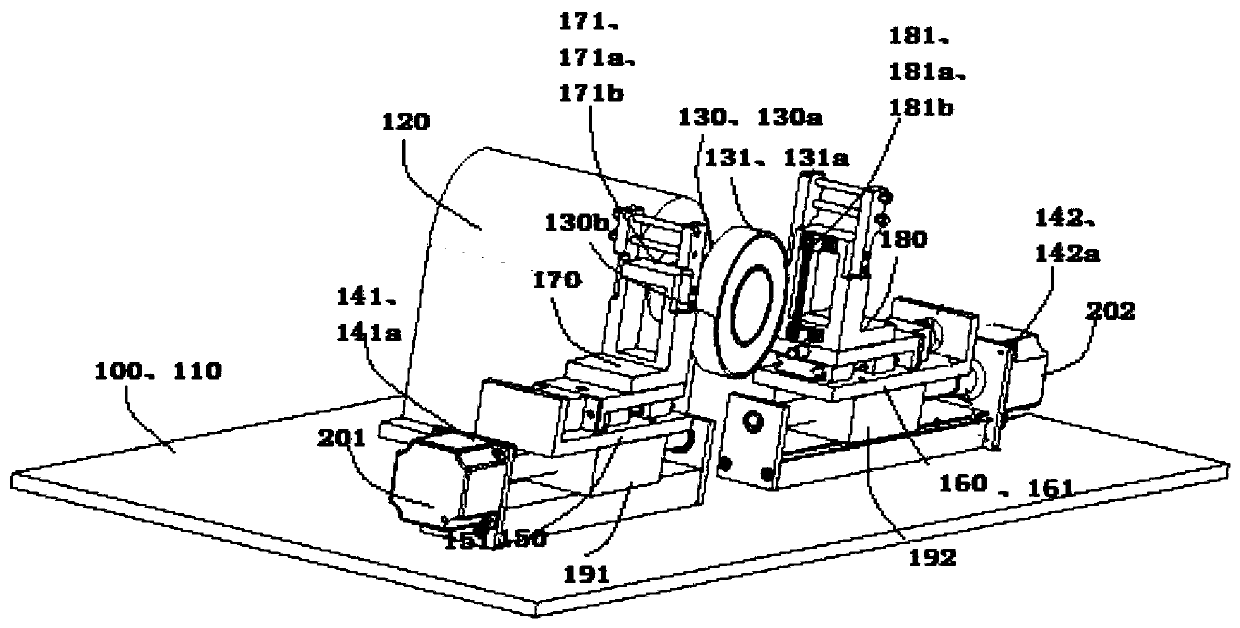

[0022] In the following, the present invention will be further explained by means of specific embodiments and working principles in conjunction with the accompanying drawings.

[0023] see Figure 1 to Figure 3 ,Such as Figure 1-3 The shown radial loading device 100 for thin-walled bearing vibration measurement includes a base plate 110, a thin-walled bearing vibrometer 120 installed above the base plate 110, and a thin-walled bearing 130 installed along the axis 130a with the thin-walled bearing vibrometer 120 On the main shaft 121 of the thin-walled bearing 130, specifically the flexspline bearing 131 is in the radial loading direction 130b of the thin-walled bearing 130, and the inner ring 132 is installed on the main shaft 121 of the thin-walled bearing vibrometer 120.

[0024] On both sides of the radial loading direction 130b of the thin-walled bearing, symmetrical slide rails 141 and 142 are provided with the axis 130a of the thin-walled bearing 130 as a symmetrical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com