Electrical control clutch booster

A technology for clutches and boosters, which is applied to clutches, mechanical equipment, etc., can solve problems such as the inability of the controller to automatically control the intake and exhaust of the booster, and achieve high shift comfort and smoothness, fast work response, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

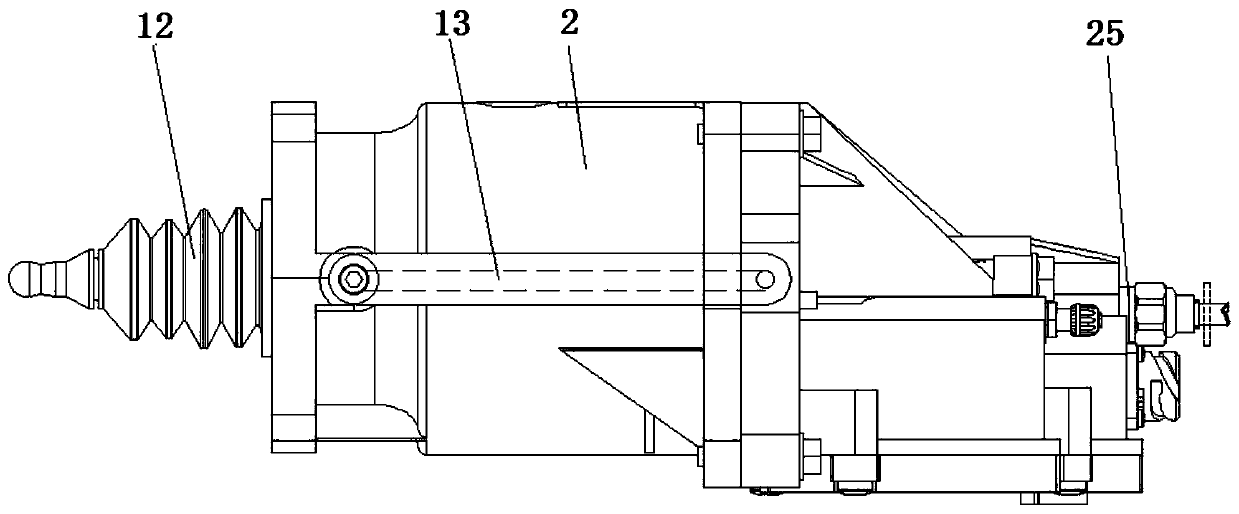

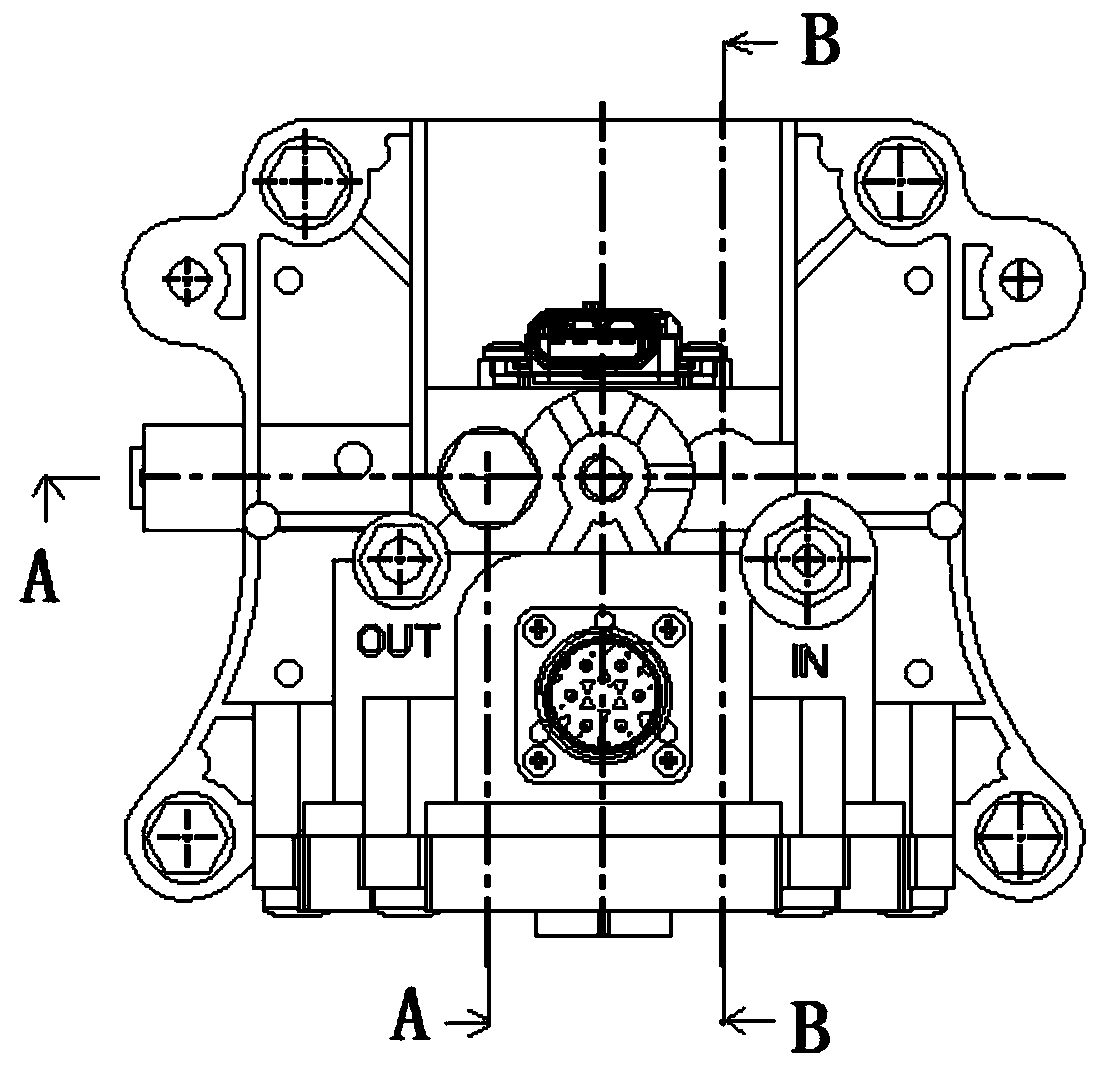

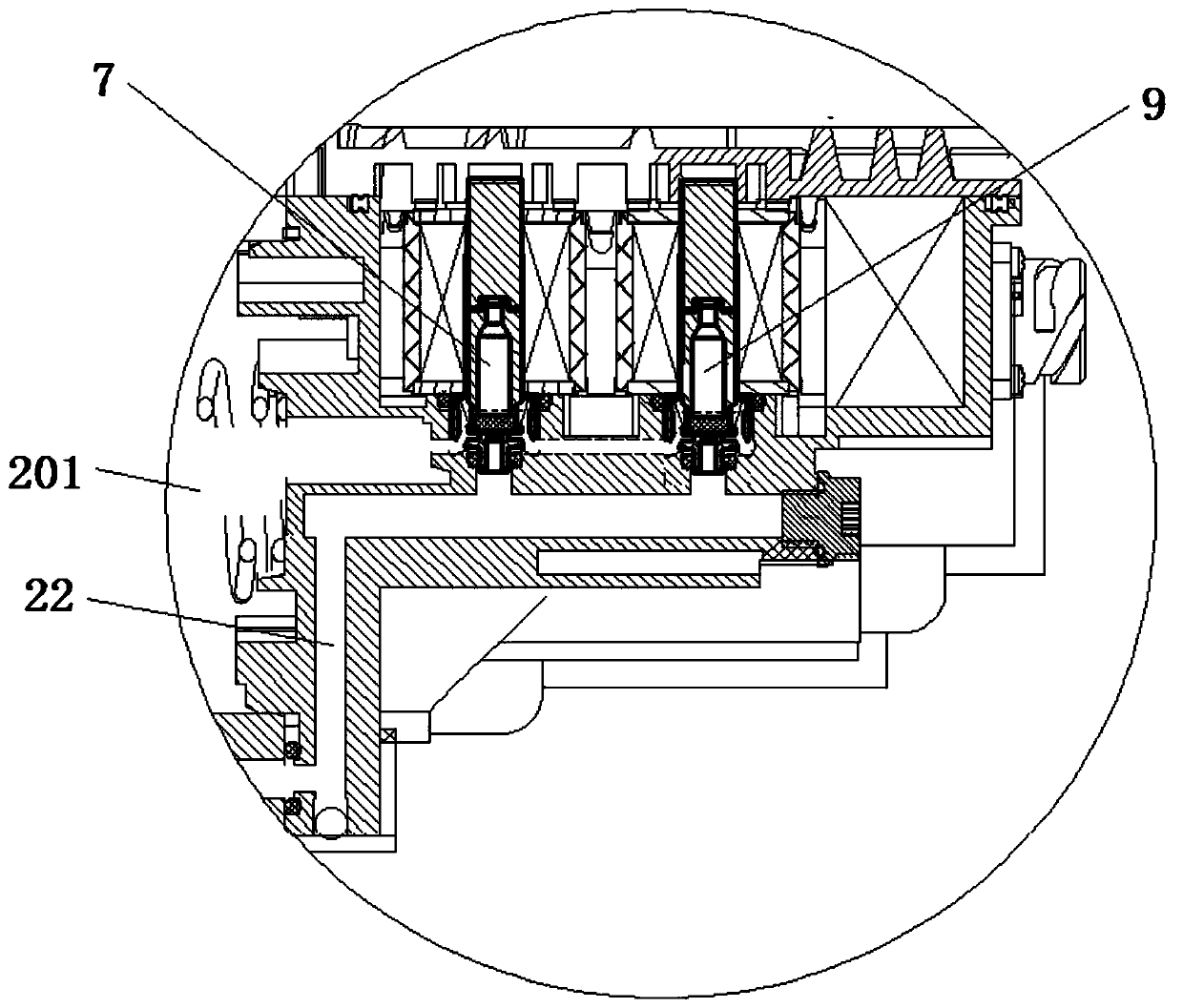

[0028] The electronically controlled clutch booster, as shown in the figure, includes a cylinder body 2. A piston 1 is installed inside the cylinder body 2 to separate the inner cavity of the cylinder body 2. The piston 1 divides the cylinder body 2 into a chamber A 201 and a chamber B 202. The piston 1 1 is installed with a magnet 3, and also includes a controller 5. A Hall sensor 10 is installed on the cylinder 2. The Hall sensor 10 senses the movement of the magnet 3 in the cylinder 2 and forms a position signal to the controller 5. The position signal It is sent in the form of PWM value, and also includes the first solenoid valve 6 and the second solenoid valve 7, the first solenoid valve 6 and the second solenoid valve 7 respectively control the intake of the A chamber 201 and the B chamber 202, and the controller 5 controls the A solenoid valve 6 and a second solenoid valve 7 work. The controller 5 is a TCU controller.

[0029] Also includes a third solenoid valve 8 and...

Embodiment 2

[0045] The same as Embodiment 1, the difference is that it also includes a return spring 4, which is installed between the annular end cover 20022 and the front piston 1001 and pushes the piston 1 to move left. The return spring 4 can ensure that the piston 2 is pushed to the initial position to ensure the space of the A cavity 201 .

Embodiment 3

[0047] Same as Embodiment 1, the difference is that the front cylinder body 2001 is a cylindrical body with openings at the left and right ends, and the left end opening of the front cylinder body 2001 is sealed with a telescopic dust cover 12, and the rear cylinder body 2002 includes a small-diameter cylinder body 20021 and an annular The end cap 20022, the left end opening of the small-diameter barrel 20021, the annular end cap 20022 is located at the edge of the opening of the small-diameter sleeve 20021, the end cap 20022 is sealed and installed at the right end opening of the front cylinder body 2001, the right section of the rear piston 1002 is in contact with the small-diameter barrel The inner wall of the body 20021 forms a cavity C 203 , and the cavity C 203 communicates with the cavity A 201 . A small hole 2031 is provided on the wall near the right end of the cavity C 203 , and a channel is also included. The small hole 2031 communicates with the channel, and the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com