Omnidirectional angle-shift PDC drill for relieving rock breaking impact force

An impact force and rock-breaking technology, which is applied in the field of omnidirectional variable-angle PDC bits, can solve the problems of PDC bits not available, PDC bit wear, and failure to realize PDC, etc., to achieve flexible cutting posture, low wear rate, good cutting posture and The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

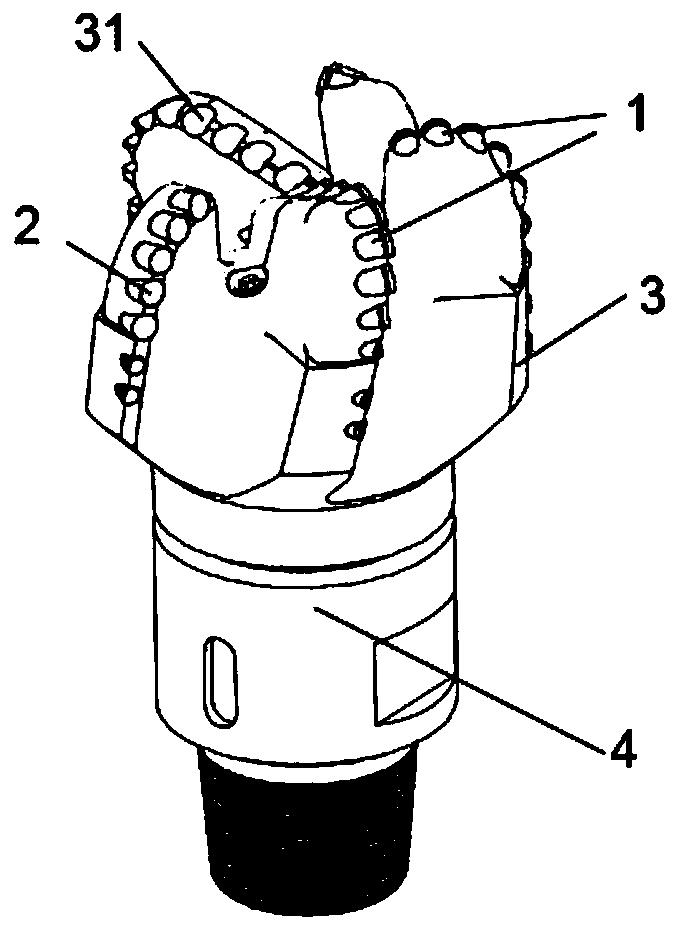

[0041] Such as figure 1 As shown, the present invention is an omnidirectional variable-angle PDC drill bit for slowing rock-breaking impact force, which is composed of omnidirectional variable-angle teeth 1, non-variable-angle teeth 2, blades 3, and base 4; the omnidirectional variable-angle teeth 1 and non-variable-angle teeth 2 are welded, inlaid, glued or screwed in the tooth groove 31 of blade 3; The number of installations is greater than or equal to zero; the blade 3 and the base 4 are integrally sintered or machined.

[0042] The types of the non-variable-angle teeth 2 include circular teeth, elliptical teeth, wedge-shaped teeth, conical teeth, spherical teeth and space curved teeth.

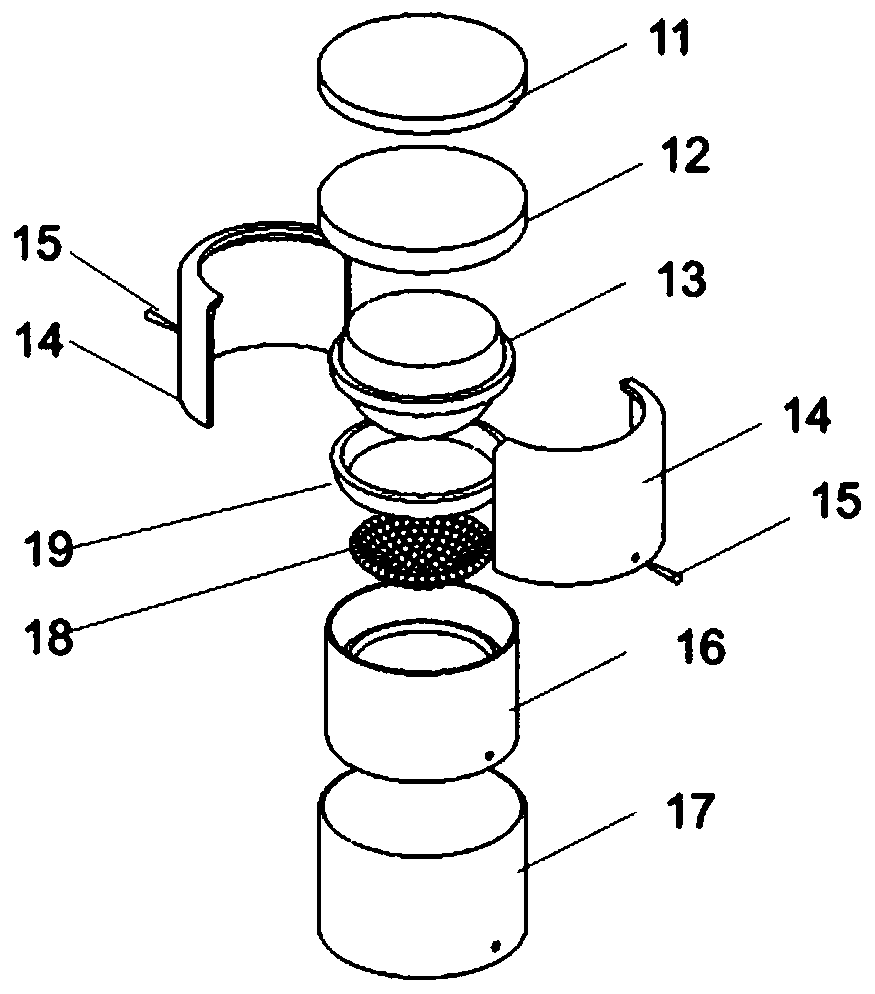

[0043] Such as figure 2 As shown, the omnidirectional variable-angle tooth 1 is composed of a cutting element 11, a support member 12, an omnidirectional rotating ball 13, a half stop ring 14, a tapered pin 15, a ball support seat 16, a packaging box 17, and a ball assembly 18 It is a...

Embodiment 2

[0055] Embodiment 2: Assembly of omni-directional variable-angle tooth 1

[0056] An omnidirectional variable-angle PDC drill bit of the present invention that slows down the rock-breaking impact force, the assembly process of its omnidirectional variable-angle tooth 1 is: firstly, the ball assembly 18 is placed on the inner curved surface 163 of the ball support seat 16, and then the elastic buffer The ring 19 is placed on the support ring 162 of the ball support seat 16, and then the omnidirectional rotating ball 13 welded with the cutting element 11 and the support member 12 is placed on the elastic buffer ring 19, and the two half stop rings 14 are fastened respectively On the outside of the ball support seat 16, the packaging box 17 is finally put on, and the cutting tooth is locked with a conical pin 15, so that the omnidirectional variable-angle tooth 1 formed is as follows: Figure 9 (a) shown.

Embodiment 3

[0057] Example 3: Working Principle of Omnidirectional Variable Angle PDC Bit

[0058] Such as Figure 9 As shown, the present invention is an omnidirectional variable-angle PDC drill bit that slows down the rock-breaking impact force, and relies on the omnidirectional variable-angle teeth 1 installed on the blade 3 to perform self-adaptive omnidirectional variable-angle adjustment:

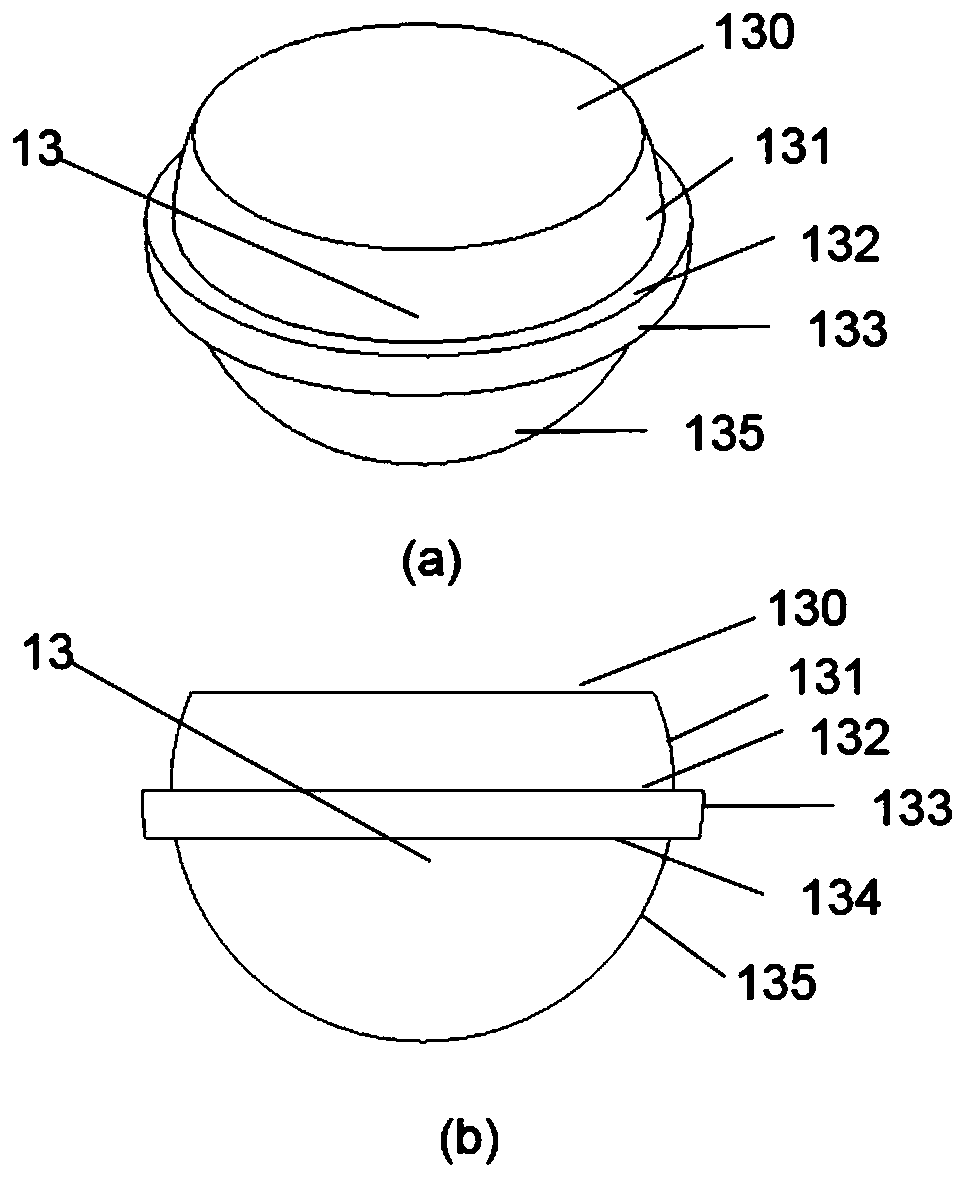

[0059] ① Omni-directional variable angle: The omni-directional rotating ball 13 built in the omni-directional variable-angle tooth 1 on the drill bit and the ball support seat 16 form a rolling pair, and then the omni-directional rotating ball 13 and the ball support seat 16 realize a full range of motion. Rotation in the same direction, so that the cutting element 11 can be adjusted in a variable angle in space;

[0060] ② Shock reduction: In medium-soft formations, the forward angle and side angle of the omnidirectional variable-angle tooth 1 will not change or change very little. At this time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com