Automatic polishing workroom suitable for combined cabinet handles

A technology for workshops and combined cabinets, which is applied in the direction of grinding workpiece supports, grinding machines, manufacturing tools, etc., and can solve the time-consuming and labor-intensive problems of furniture grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

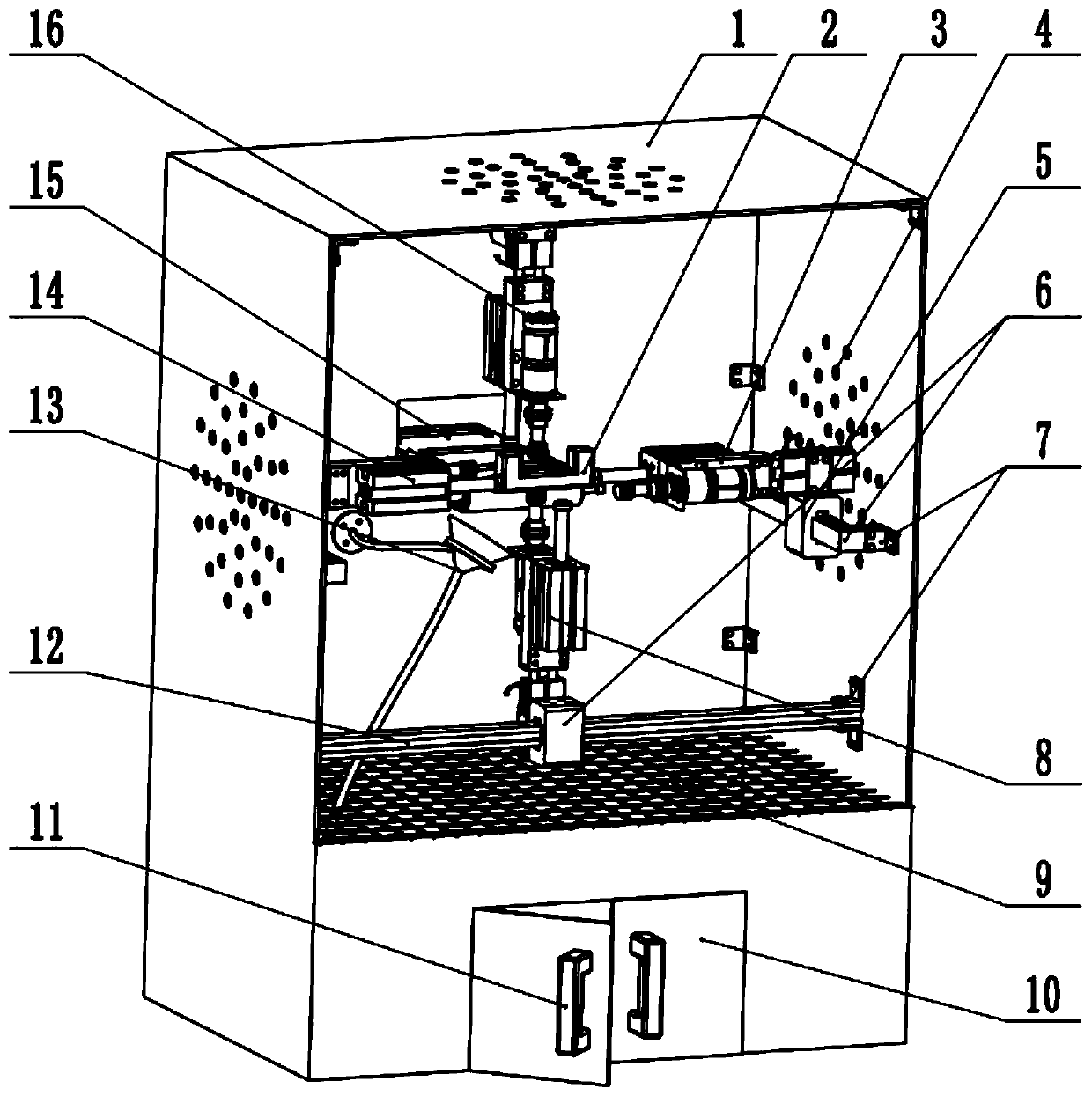

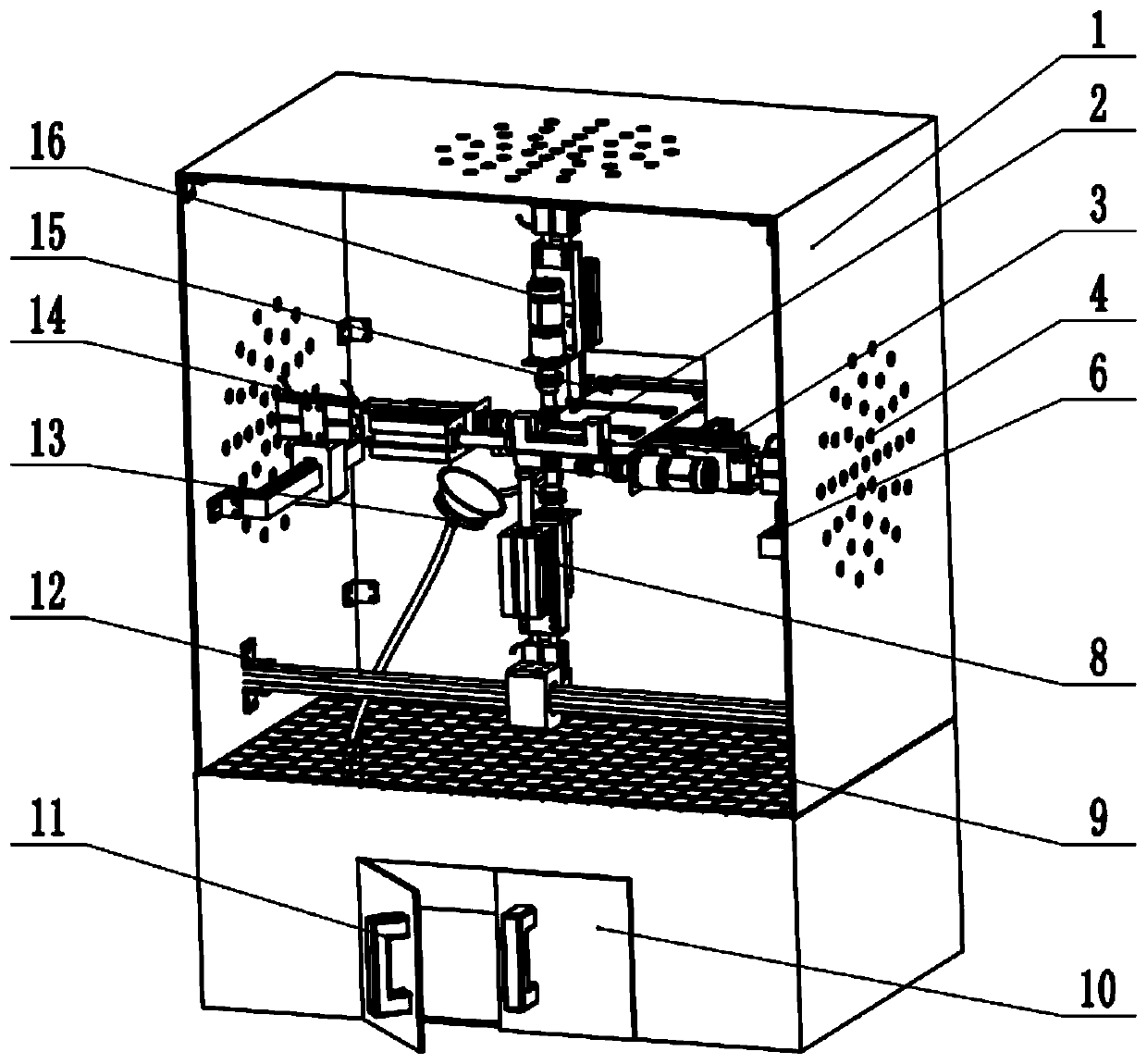

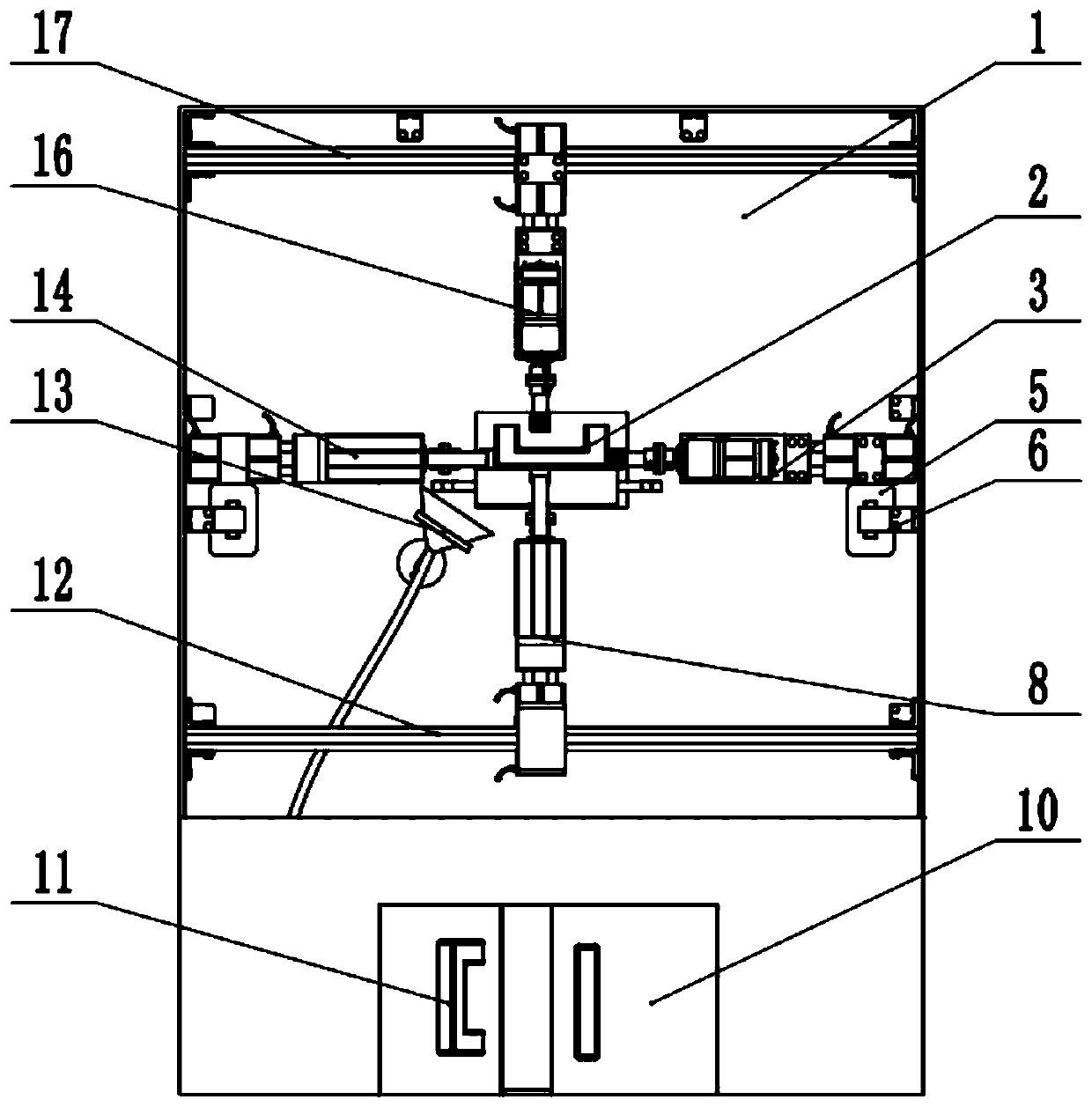

[0031] An automatic grinding workshop suitable for handles of combined cabinets is composed of a working partition plate 1, a first processing device 3, a sliding mechanism 5, a guiding mechanism 6, a bottom processing device 8, a dust-proof net 9, a door panel 10 of a dust collection room, Dust room door panel handle 11, bottom slide rail 12, dust suction device 13, second processing device 14, feeding device 15, top processing device 16 and top slide rail 17, the top of the working partition board 1 and There are exhaust holes 4 on both sides. The first processing device 3 is horizontally installed on the top of the sliding mechanism 5 through the cylinder fixing plate 313 and the screw. There are forward ventilation holes 301 and retreat ventilation holes 303 at the top of the biaxial double-rod cylinder 302, and the push rod of the biaxial double-rod cylinder 302 is connected with the installation platform 304 through the installation platform fixing plate 312 and screws, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com