Continuous casting blank thickness online measuring and pressing amount adjusting system

A technology for adjusting the system and continuous casting slab, which is applied in the direction of measuring devices, configuration of indicating equipment/measuring equipment, casting equipment, etc., can solve problems such as the influence of slab solidification quality, and achieve the effect of improving the solidification quality of slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

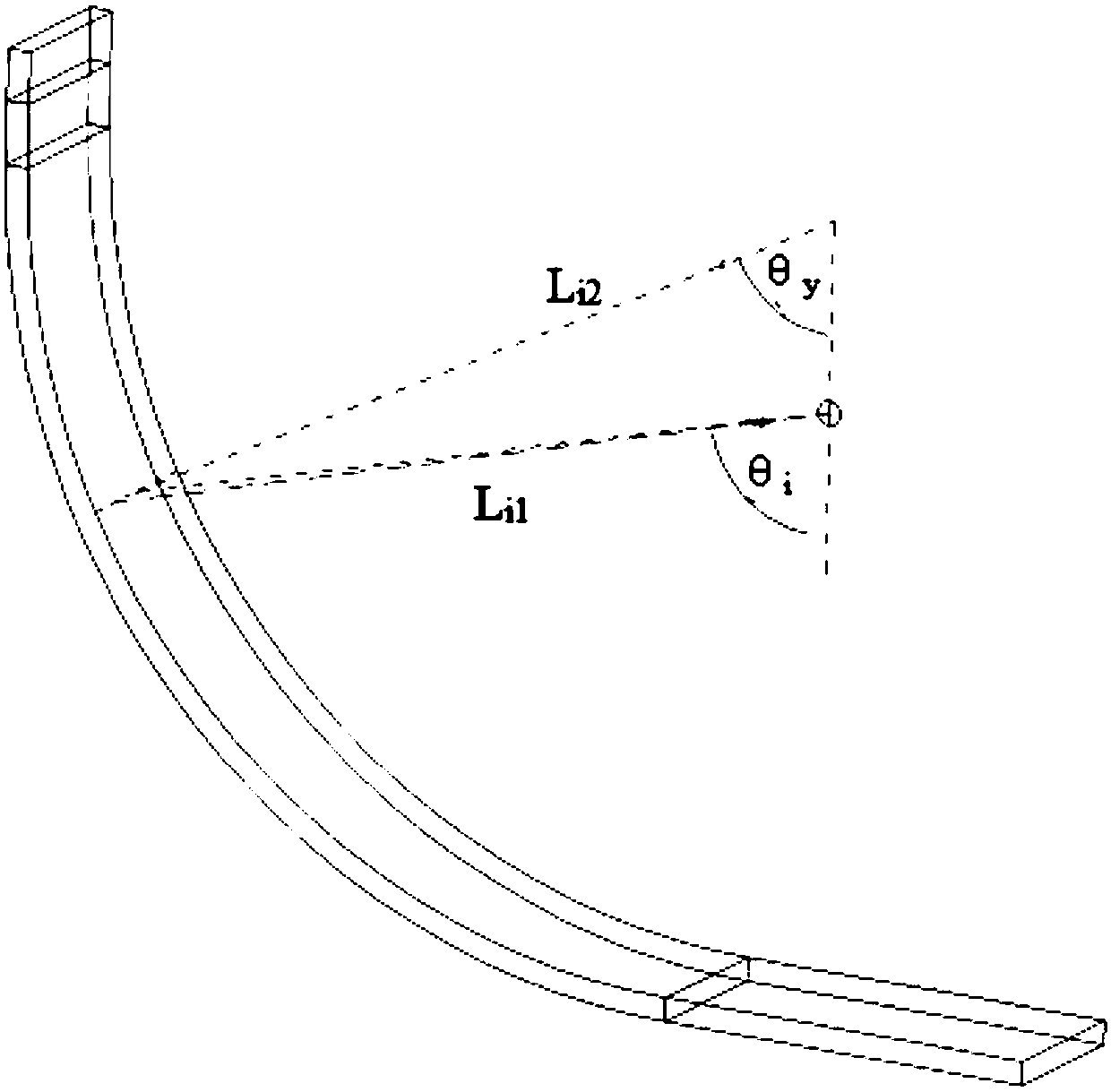

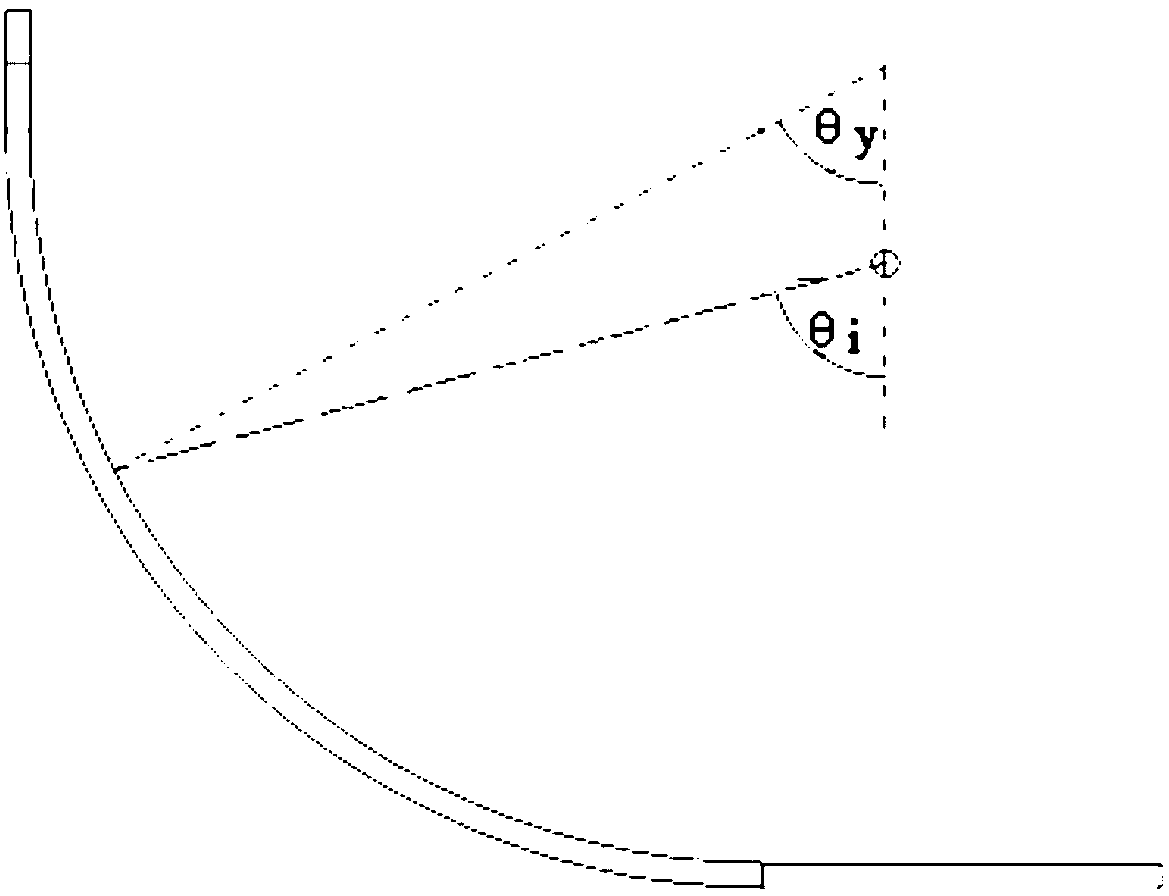

[0048] Embodiment 1: A continuous casting slab thickness online measurement and reduction adjustment system in this embodiment, such as the schematic diagram of the device (attached Figure 1-3 ) shows, including a continuous casting slab online infrared distance measuring probe, casting slab thickness calculation feedback system and continuous casting machine reduction adjustment system. The accuracy of the distance measuring device is 100 μm, and the distance measurement error is ≤100 μm. The distance measurement probe is fixed on the center surface of the straight arc or arc continuous casting machine in the width direction, and at the center of the inner arc of the arc segment. The online distance measurement device can be three-dimensional along the fixed point Turn, the measurement work can cover the designated measurement area, and dust, high and low temperature, and moisture protection measures are installed on the probe.

[0049] The slab online distance measuring dev...

Embodiment 2

[0052] Embodiment 2: A kind of continuous casting rectangular slab thickness on-line measurement and reduction adjustment system, such as device schematic diagram (attached Figure 1-3 ), including two online acoustic ranging probes for continuous casting slabs, a slab thickness calculation feedback system and a continuous casting machine reduction adjustment system. The accuracy of the distance measuring device is 100μm, and the distance measurement error is ≤100μm. One of the distance measurement probes is fixed on the non-central surface in the width direction of the straight arc or arc continuous casting machine, 2m below the center of the inner arc of the arc section, and the other is fixed on the straight arc. On the non-center surface in the width direction of the arc or arc continuous casting machine, 3m above the center of the inner arc of the arc segment. The online distance measuring device can rotate three-dimensionally along the fixed point, and the measurement wo...

Embodiment 3

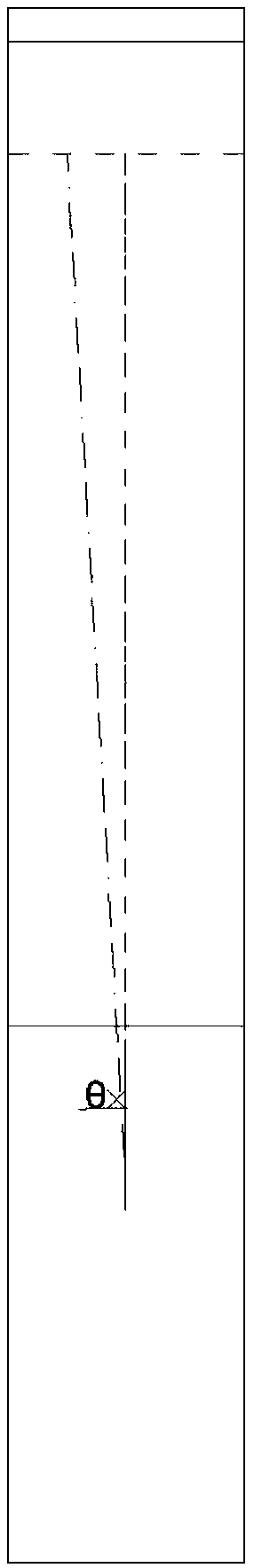

[0054] Embodiment 3: A kind of continuous casting round slab diameter on-line measurement and reduction adjustment system, such as the schematic diagram of the device (attached Figure 2-6 ), including an on-line electromagnetic distance measuring probe for continuous casting slabs, a feedback system for calculating slab thickness and a continuous casting machine reduction adjustment system. The accuracy of the distance measuring device is 100 μm, and the distance measurement error is less than or equal to 100 μm. The distance measurement device is fixed on the vertical surface of the straight arc or arc continuous casting machine including the center line of the round billet, and at the center of the inner arc of the arc segment. The online distance measurement device can Rotating along the fixed point in the center of the circle, the measurement work can cover the designated measurement area, and dust, high and low temperature, and moisture protection measures are installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com