Grate-rotary kiln pellet flue gas ultra-low emission system

An emission system and rotary kiln technology, applied in gas treatment, combined device, membrane technology, etc., can solve the problems of denitrification efficiency, production load impact, unstable NOx emissions, low denitrification and desulfurization efficiency, etc., and achieve stable operation and equipment. Simple, low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

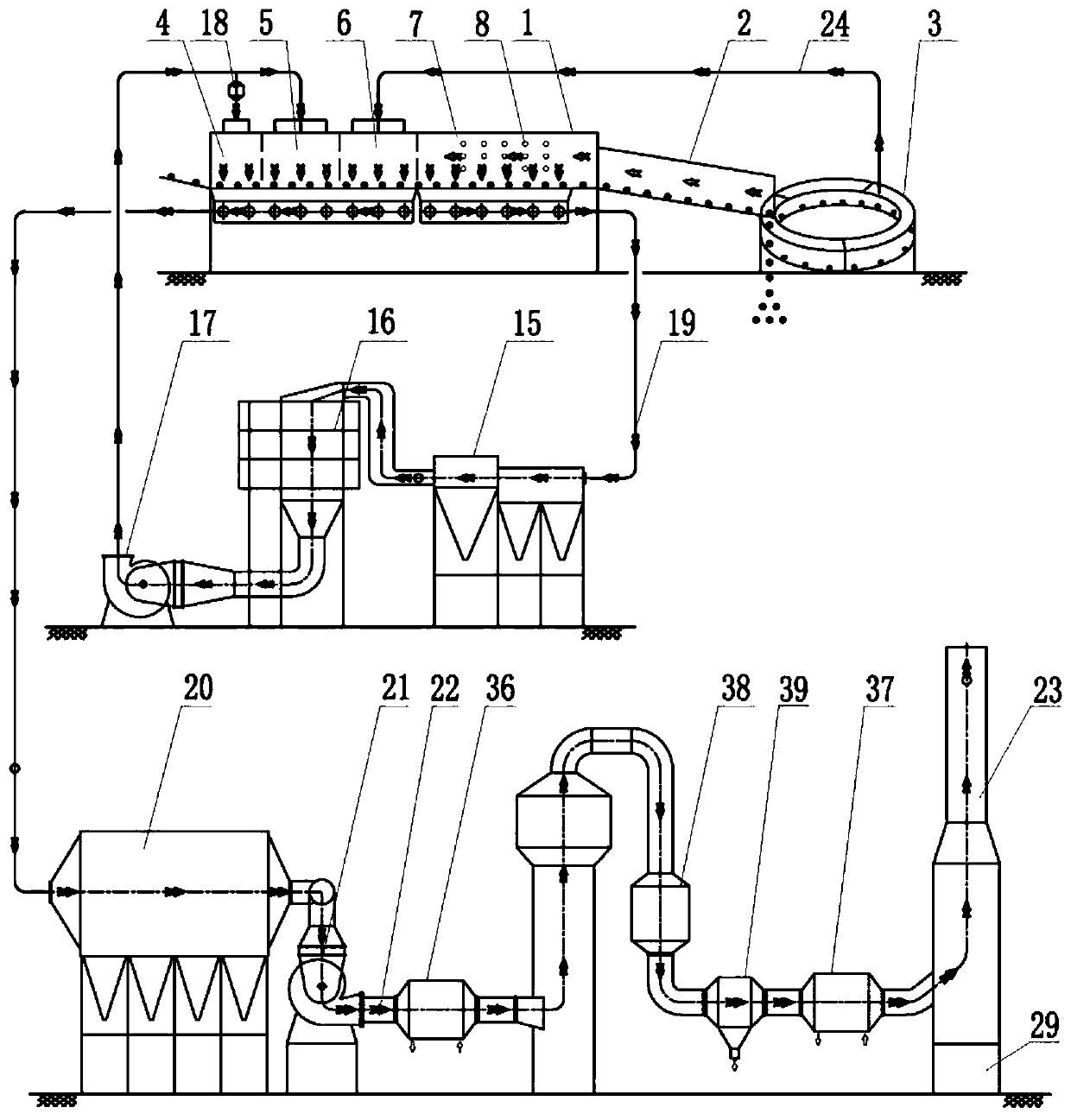

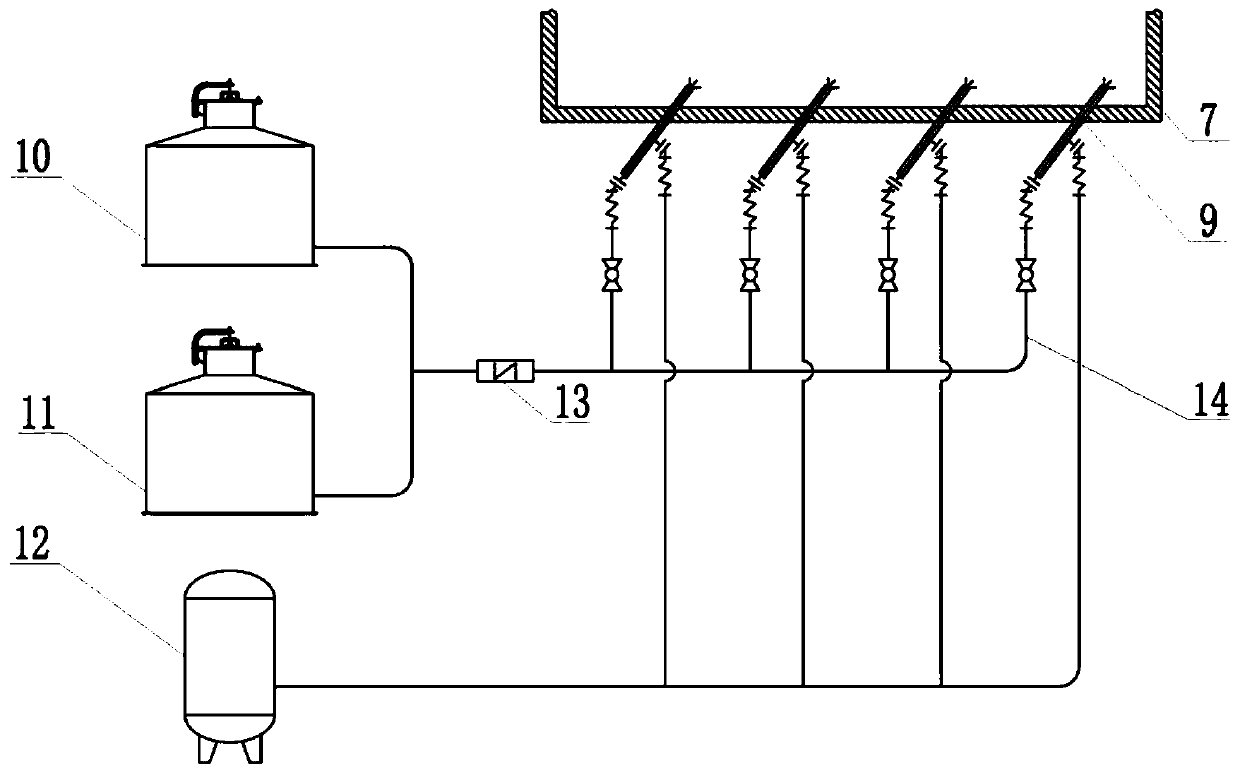

[0050] Reference figure 1 , The present invention provides a grate-rotary kiln pelletized ultra-low emission system, including the chain grate 1, rotary kiln 2 and ring cooler 3 connected in sequence, that is, the grate 1 is connected to the rotary kiln 2. The head, the ring cooler 3 is connected to the tail of the rotary kiln 2. The pellets are processed by the grate machine 1, the rotary kiln 2 and the ring cooler 3 before being discharged; among them, the grate machine 1 is away from the side of the rotary kiln 2 To the other side, it is divided into drying section 4, drying section 5, preheating section 6, preheating section 7; the flue gas outlet on the ring cooler 3 is connected to the flue gas of the grate machine 1 through the first flue path 24 On the gas inlet, this design is to recover the heat of the flue gas in the ring cooler 3; a first denitrification device 8 is provided in the second preheating section 7; the flue gas outlet at the bottom of the second preheatin...

Embodiment 2

[0080] This embodiment is an adjustment made on the basis of embodiment 1. This embodiment is adjusted for the desulfurization tower, and no other structure is changed.

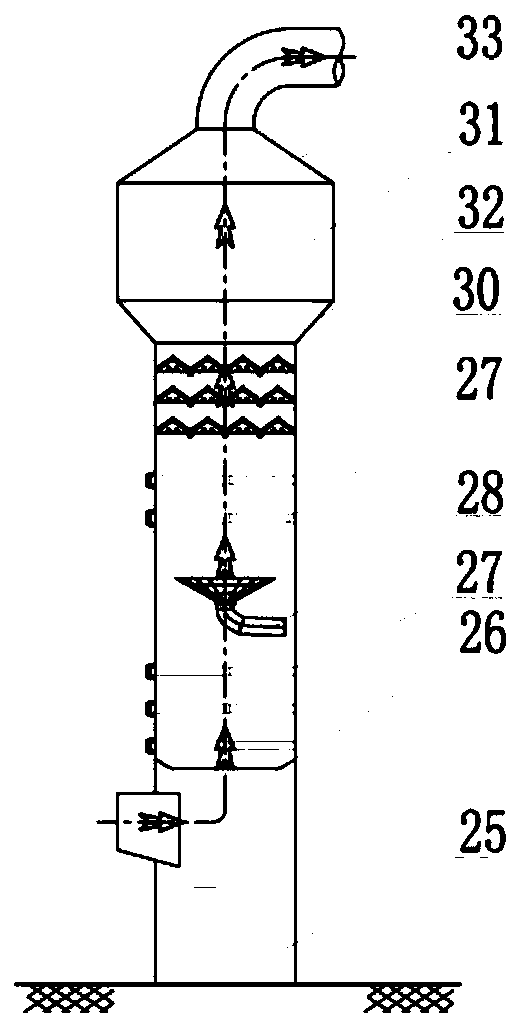

[0081] Specifically, refer to Figure 4 , In this embodiment, the desulfurization tower is a double tower and double circulation tower.

[0082] The double-tower double-circulation tower is divided into a first-stage tower 34 and a second-stage tower 35. In the first-stage tower 34, a first-stage slurry area 25, a liquid holding tray 26, and a first-stage spray layer 27 are arranged from bottom to top; and the second-stage tower 35 A secondary slurry area 29, a liquid holding plate 26, a spray layer 27, a mist removal device 30, and a third dust removal device 31 are sequentially arranged from bottom to top. The air outlet of the primary tower 34 is connected to the air inlet of the secondary tower 35, The primary tower 34 is a primary circulation system, and the secondary tower 35 is a secondary circulation syste...

Embodiment 3

[0087] This embodiment is an adjustment made on the basis of Embodiment 1 or 2. This embodiment is adjusted for the whitening device, and other structures are not changed.

[0088] Reference Figure 5 In this embodiment, the whitening device is a “one cooling and one heating” device, and “one cooling” is a heat extractor 36. The heat extractor 36 is arranged between the first fan 21 and the desulfurization device. After the heater 36, the temperature drops from 150°C to 110°C; “one temperature rise” is the temperature riser 37, which is located in front of the air inlet of the chimney 23. After the flue gas passes through the temperature riser 37, the temperature rises from 50°C to 80°C; The heat exchanger 36 and the temperature riser 37 exchange heat through a circulating heat medium water system. In this embodiment, when the atmospheric environment temperature is 5° C. and the humidity is 50%, there is no visible white smoke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com