Blowback device for filter cartridges of dust remover

A technology of back-flushing device and dust collector, applied in the field of separation, can solve the problems of low dust removal rate, easy adsorption of dust on the surface of the filter cartridge, etc., and achieve the effects of commissioning airtightness, improving dust removal rate, and convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

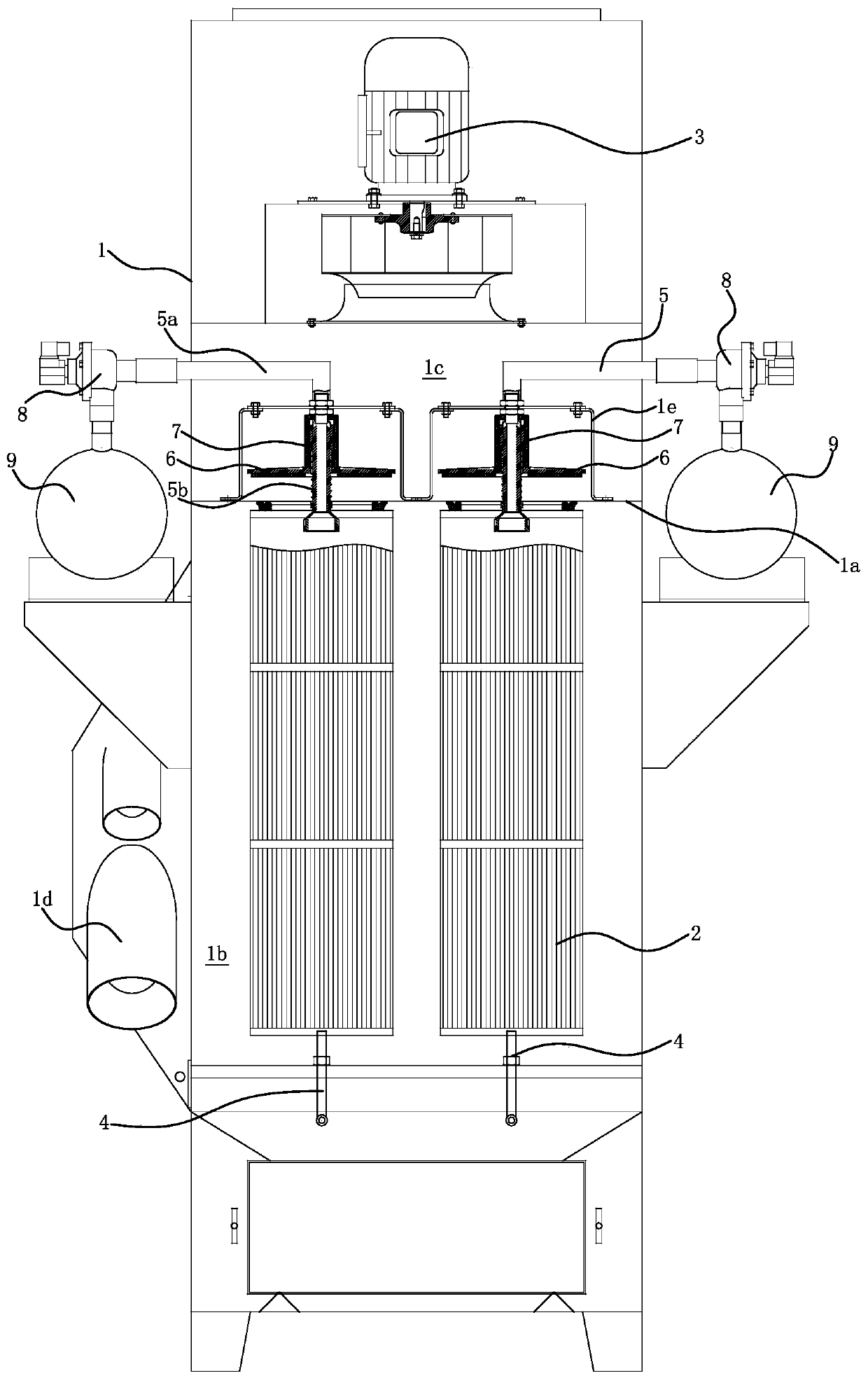

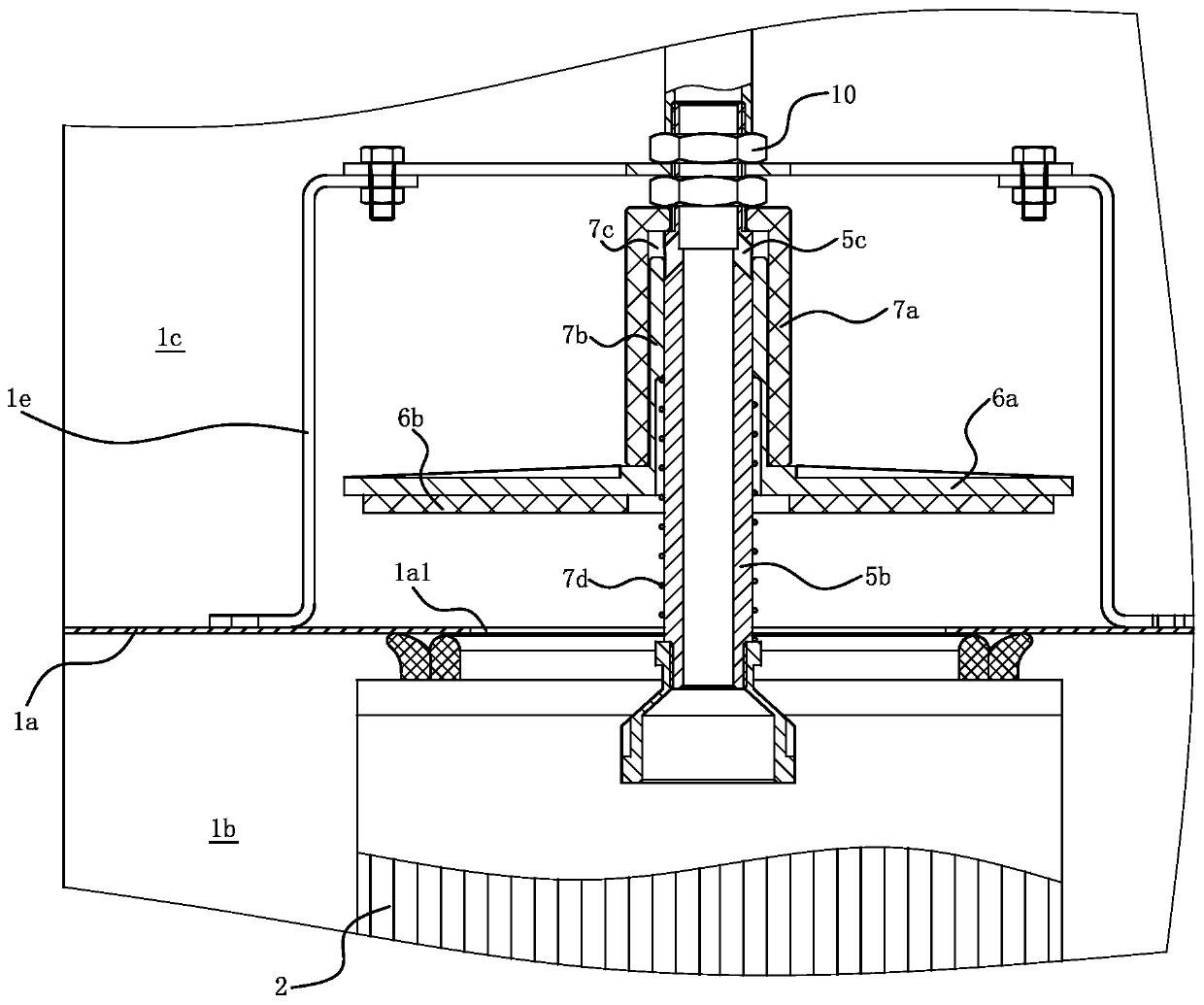

[0015] Embodiment 1: The dust collector includes a box body 1 and a filter cartridge 2. There is a horizontal partition 1a in the box body 1. The partition board 1a divides the inner cavity of the box body 1 into a dust removal chamber 1b and an air outlet chamber 1c. The air outlet chamber 1c is located at Above the dust chamber 1b. One or more air passage holes 1a1 are opened on the partition 1a, and the air passage holes 1a1 connect the dust removal chamber 1b with the air outlet chamber 1c. An air intake pipe 1d is installed on the side wall of the dust removal chamber 1b, and a fan 3 is installed on the top wall of the air outlet chamber 1c. When the fan 3 is running, the airflow enters the dust removal chamber 1b from the air inlet pipe 1d, enters the air outlet chamber 1c through the air hole 1a1, and finally passes through Fan 3 is discharged to the outside of casing 1.

[0016] The filter cartridge 2 is located in the dust removal chamber 1b of the box body 1. The fi...

Embodiment 2

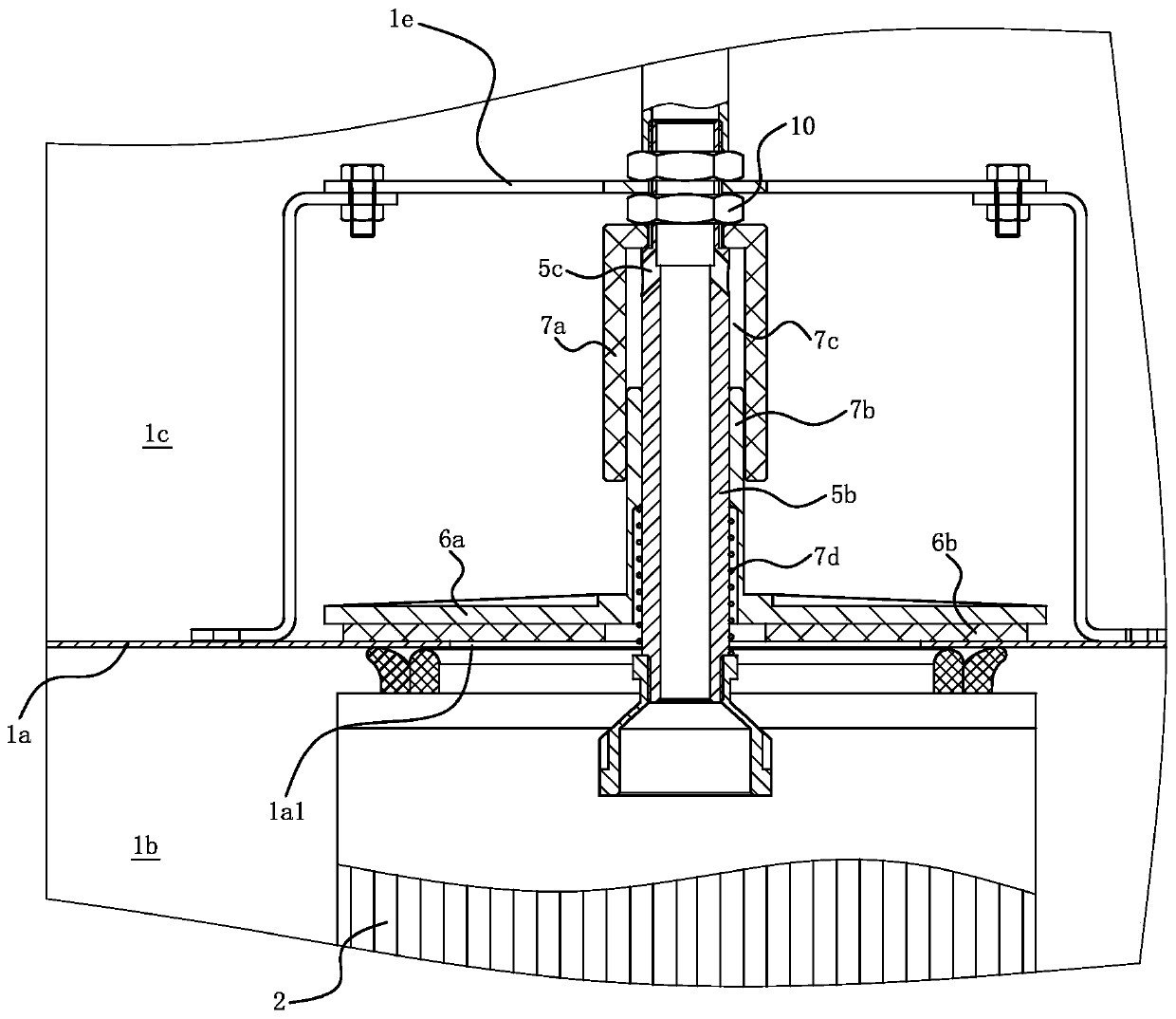

[0022] Embodiment 2: The structure and principle of this embodiment are basically the same as that of Embodiment 1. The basic similarities will not be described repeatedly, only the differences will be described. The difference lies in: the cover plate 6 and the pneumatic drive mechanism 7 are located in the box Below the partition plate 1a of the body 1, that is, the cover plate 6 and the pneumatic drive mechanism 7 are located inside the filter cartridge 2; the upper end of the piston 7b is fixedly connected with the cover plate 6. The spring 7d makes the piston 7b always move downward. When the injection of high-pressure gas into the air chamber 7c is stopped, the spring 7d drives the cover plate 6 to move downward, so that the cover plate 6 overcomes the airflow thrust generated by the fan 3, ensuring that the cover plate 6 Disengaged from the separator 1a and maintained in a state of being separated from the separator 1a.

Embodiment 3

[0023] Embodiment 3: The structure and principle of this embodiment are basically the same as that of Embodiment 1. The basic similarities are no longer redundantly described, and only the differences are described. The difference is that the pneumatic drive mechanism 7 is a cylinder, and one of the cylinders The air chamber 7c communicates with the blowback air pipe 5 , and a guide structure is formed between the cover plate 6 and the vertical section 5b of the back blow air pipe 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com