Disinfection cabinet

A disinfection cabinet and liner technology, which is applied in the field of disinfection cabinets, can solve the problems of cabinet rot, mildew, ineffective volatilization, etc., and achieve the effect of maintaining aesthetics, simple structure, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

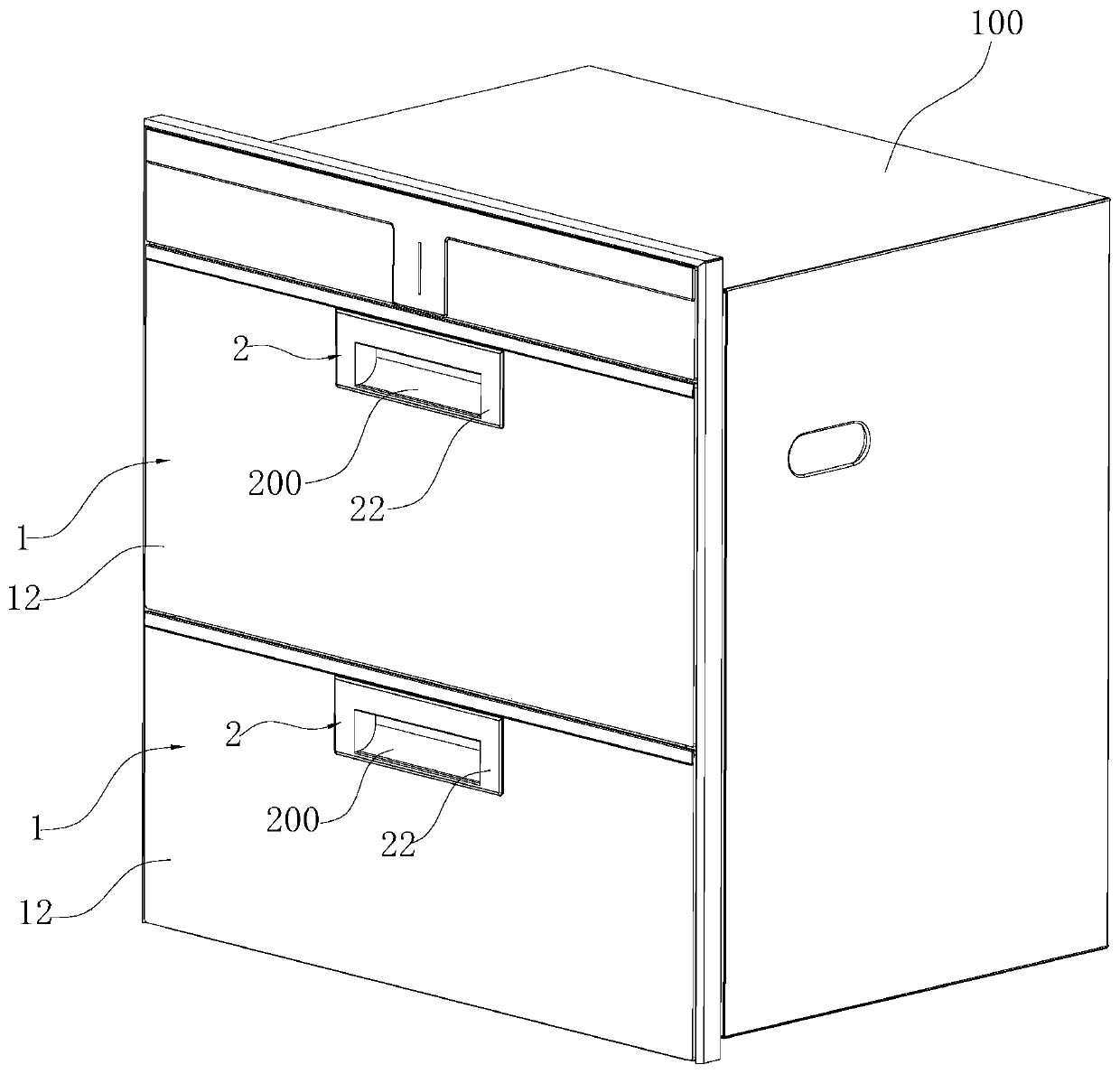

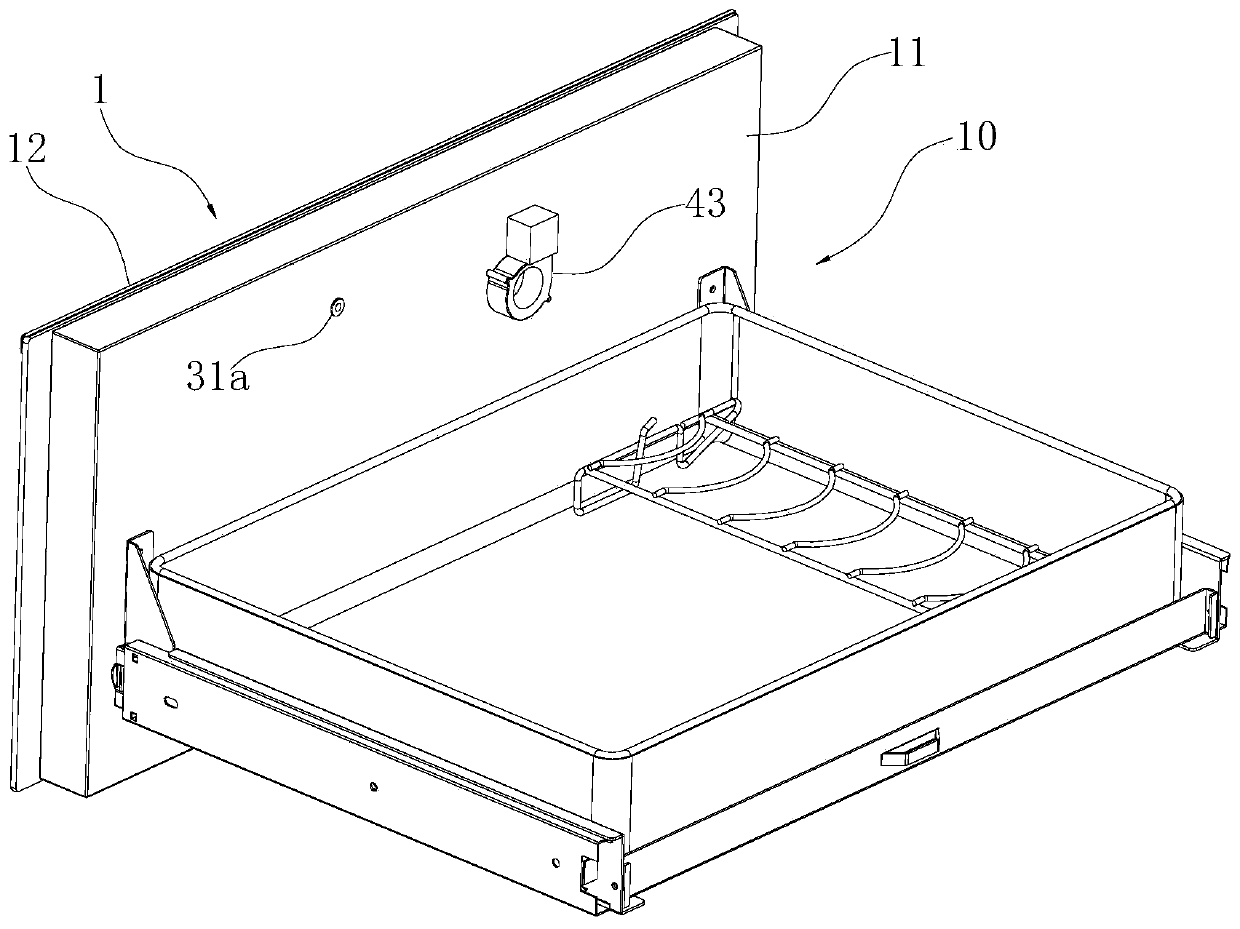

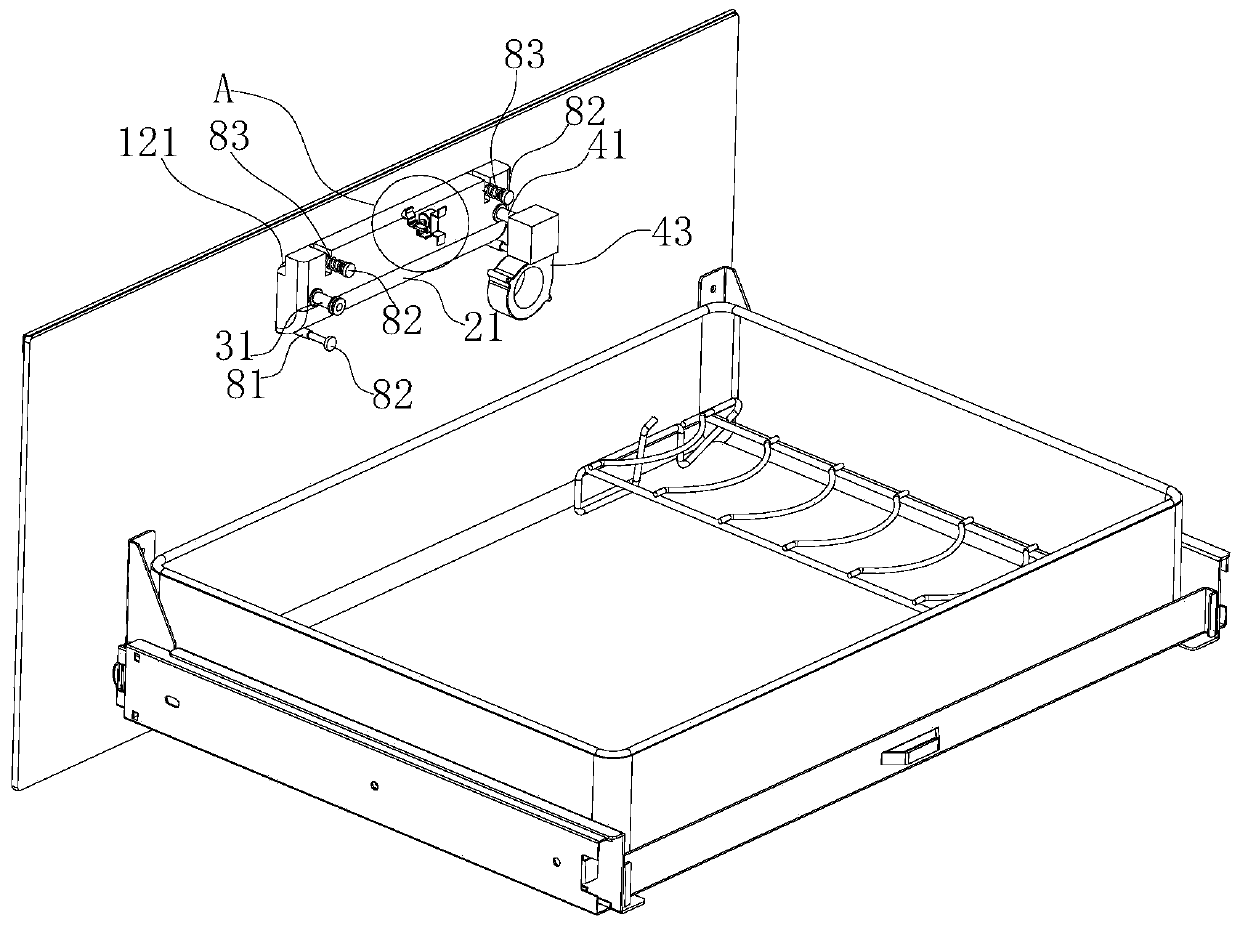

[0036] Such as Figure 1-8As shown, a disinfection cabinet includes a cabinet body 1, the front of which is open and its inner cavity is the inner container of the disinfection cabinet. In this embodiment, two drawers 10 are arranged above and below the inner container, and the drawer panels of each drawer 10 respectively constitute the door body 1 of the disinfection cabinet and cover the opening of the inner container. Each door body 1 includes a box-shaped door frame 11 and a panel 12, the panel 12 covers the opening of the door frame 11, and the panel 12 is provided with an installation opening 121, and a handle 2 is embedded in the installation opening 121, The panel 12 and the door frame 11 enclose a space 10 a capable of accommodating the handle 2 , and the handle 2 includes a handle body 21 and a handle panel 11 arranged on the front face of the handle body 21 .

[0037] The above-mentioned handle 2 is provided with an air intake mechanism and an exhaust mechanism, wh...

Embodiment 2

[0044] Such as Figure 9 with Figure 10 As shown, the difference from Embodiment 1 is that in this embodiment, an air inlet 311 is provided on the wall of the inlet end of the intake pipe 31, and an exhaust hole 411 is provided on the wall of the exhaust end of the exhaust pipe 41. , the first blocking member 32 and the second blocking member 42 are sleeves fixed on the handle 2, and the intake end of the intake pipe 31 and the exhaust end of the exhaust pipe 41 can be respectively inserted into the corresponding sleeves, And can move back and forth respectively relative to the corresponding sleeve, so that the air intake hole 311 on the air intake pipe 31 and the exhaust hole 411 on the exhaust pipe 41 can be blocked or opened by the side wall of the sleeve respectively.

Embodiment 3

[0046] Such as Figures 11-14 As shown, the difference from Embodiment 1 is that the middle part of the turning linkage 52 in this embodiment is fixed with a roller bar 5222 extending perpendicularly to the turning linkage 52 , and the junction between the roller bar 5222 and the turning linkage 52 The above-mentioned shaft hole 520 is formed at the position, and the free end of the roller rod 5222 is formed with a U-shaped groove 5223, the above-mentioned roller 5221 is installed in the U-shaped groove 5223, and the above-mentioned contact surface 61 is arranged on the top surface of the first connecting member 6 , and the free end of the first connecting member 6 has a stopper 63 extending upwards, and when the roller 5221 abuts against the contact surface 61 on the first connecting member 6 , the stopper 63 is limited to the rear side of the roller 5221 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com