Filter screen of range hood, air inlet system of range hood and range hood

A range hood and air intake system technology, which is applied in the range hood field, can solve the problems of less oil fume and small contact area, and achieve the effect of ensuring the effect, ensuring the contact area, and increasing the total area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

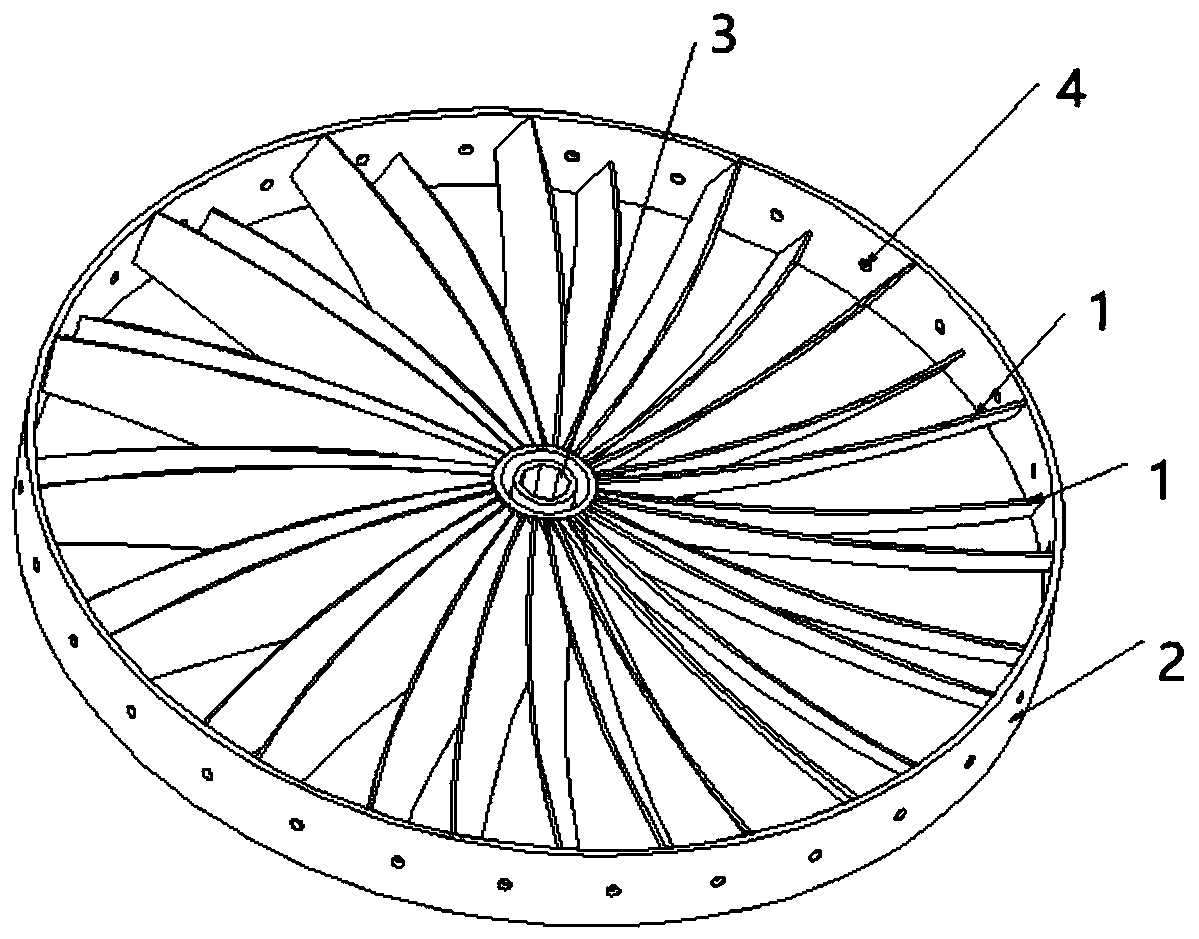

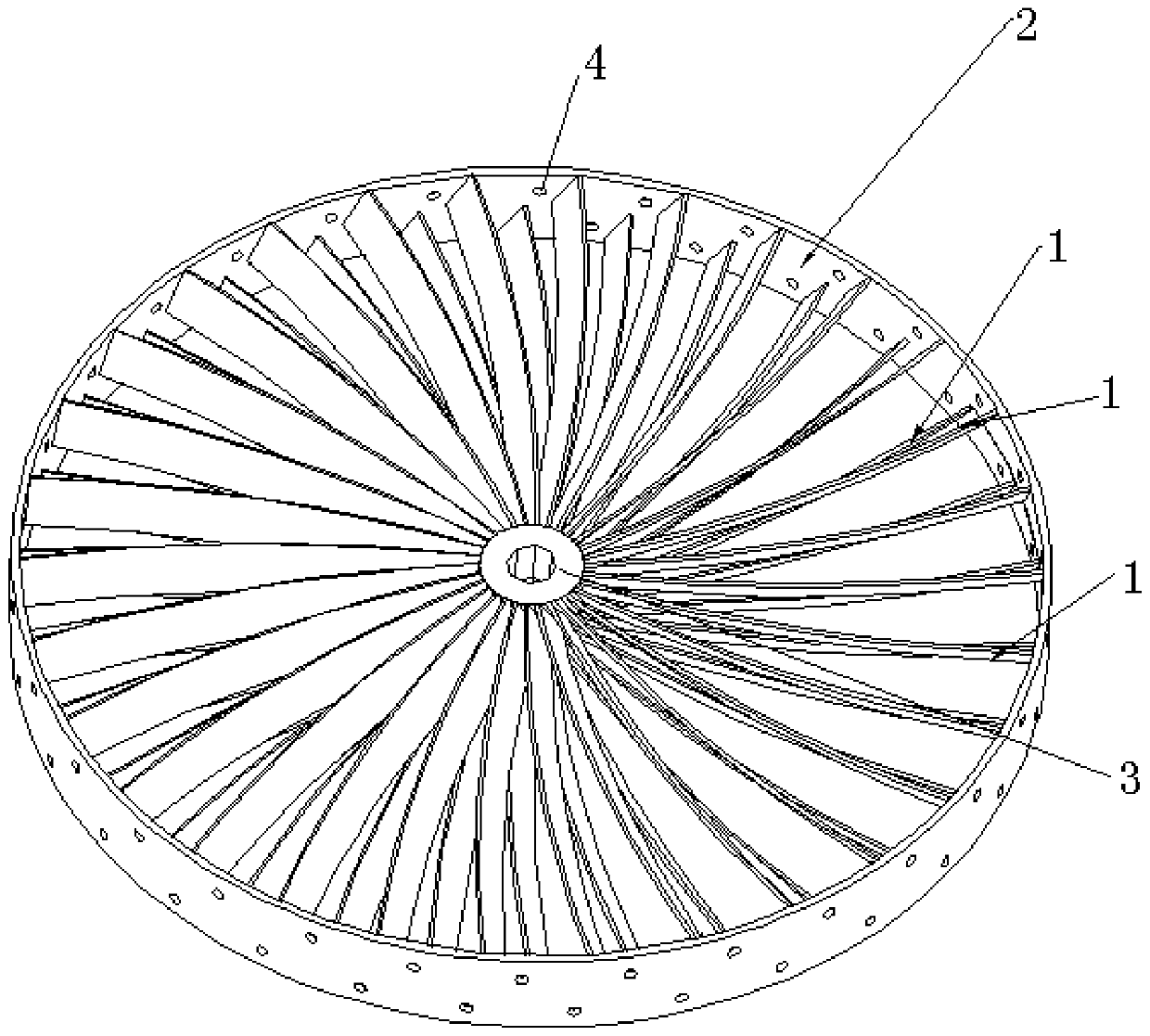

[0045] This embodiment provides a filter screen for a range hood, such as figure 1 , including a mounting plate 3, a rim 2, and a plurality of blades 1 radially arranged between the mounting plate 3 and the rim 2 with the mounting plate 3 as a center.

[0046] Wherein, the mounting disc 3 is suitable for being installed on the output shaft 8 of the motor 7 , and when the motor 7 rotates, the mounting disc 3 is driven to drive the blade 1 to rotate. The rim 2 is arranged around the mounting disc 3 .

[0047]Several blades 1 are radially arranged between the mounting disk 3 and the rim 2 with the center of the mounting disk 3 as the center of the circle, the root of the blade 1 is installed on the mounting disk, and the end of the blade 1 Installed on the rim 2, and at least one blade 1 and the projection of the root of the adjacent blade 1 on the outer peripheral wall of the installation disk 3 are spaced apart in the axial direction of the installation disk 3, or the ends are...

Embodiment 2

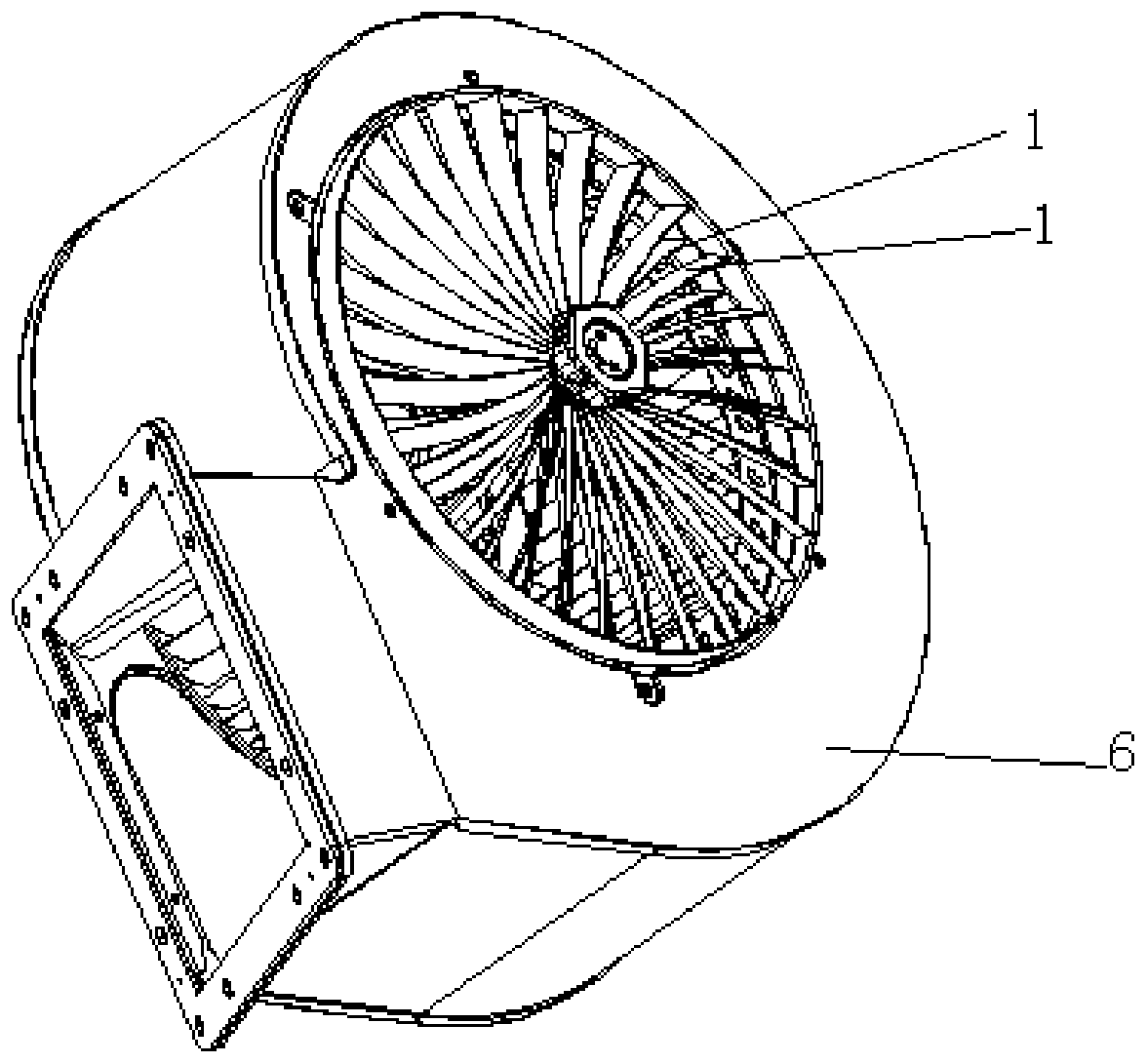

[0057] This embodiment provides an air intake system of a range hood, such as Figure 3 to Figure 5 As shown, it includes the filter screen of the range hood provided in the above embodiment, and the motor 7 , and the mounting plate 3 is installed on the output shaft 8 of the motor 7 .

[0058] Wherein the air intake system has a volute 6 and a wind wheel 5 installed in the volute 6, the wind wheel 5 is installed on the output shaft 8 of the motor 7, and the mounting plate 3 is installed on the wind wheel 5 At the air inlet, the output shaft 8 of the motor 7 is equipped with both the wind wheel 5 and the filter screen, and the structure is simple and compact, which is convenient for users to install. Such as image 3 As shown, the mounting plate 3 is mounted on the end of the output shaft 8 of the motor 7 and fixed by a lock nut. Such as Figure 5 As shown, a safety isolation net 9 is also provided on the outside of the volute 6, which can prevent the filter from hurting th...

Embodiment 3

[0062] This embodiment provides a range hood, which includes the air intake system of the range hood provided in Embodiment 2. The range hood can filter more oil fumes and has a good air intake effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com