Self-adaptive control method of heavy-duty vehicle AMT synchronizer

A technology of adaptive control and control method, which is applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., can solve the problem of synchronous force control and time control, unable to adapt to control requirements, synchronizer Impact and other problems, to avoid excessive synchronous displacement, avoid insufficient synchronous displacement, and buffer the impact of gear shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

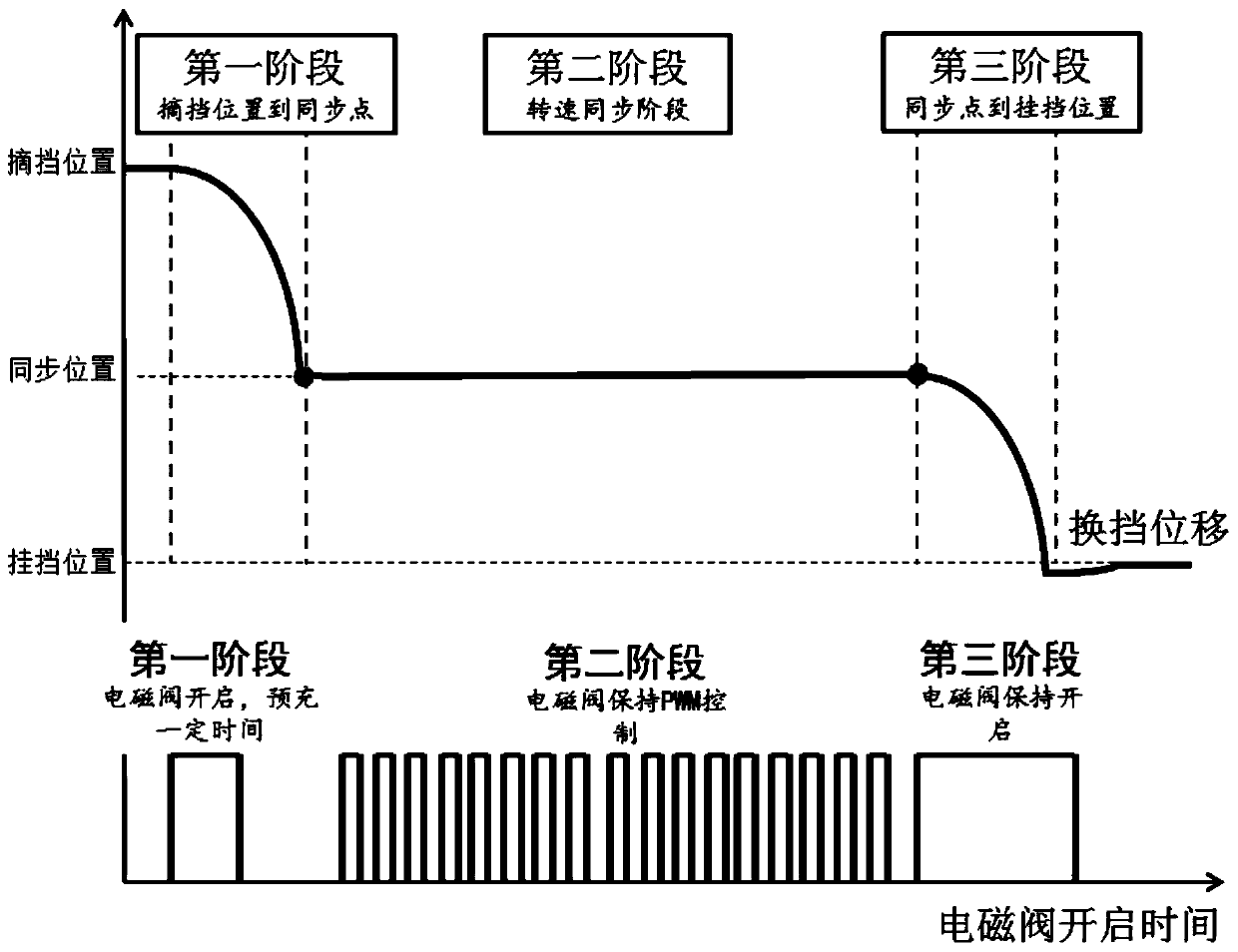

[0075] see Figure 1 to Figure 6 , a heavy-duty vehicle AMT synchronizer adaptive control method, the control method comprises the following steps:

[0076] Step 1: The synchronizer moves from the shifting position to the synchronous point, the solenoid valve of the shift actuator is kept fully open, and the pre-charging time t2 is continuously opened, so that the gearbox shift actuator quickly reaches the synchronous point;

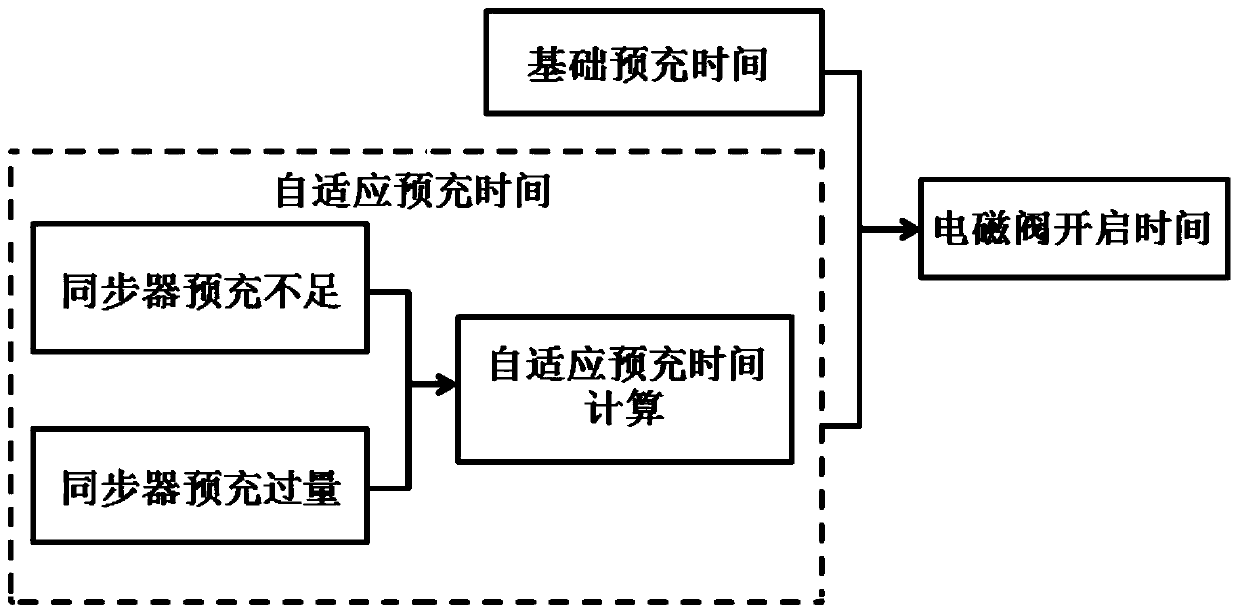

[0077] The adaptive calculation of the solenoid valve opening pre-charge time t2:

[0078] By detecting the displacement change of the shift actuator in the second stage of the speed synchronization stage of the previous shift action, it is judged whether the displacement of the shift actuator is in the correct synchronous position, so as to determine whether the current pre-charging time of the solenoid valve is appropriate, so as to automatically increase or decrease the second stage. One-stage pre-charging time to achieve the purpose of self-adaptati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com