Wall type connection damper connecting member and construction method thereof

A technology for connecting damping and connecting components, which is applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve problems such as damper installation is not in place, damper can not achieve the expected effect, etc., to achieve easy maintenance and Replacement, simple structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

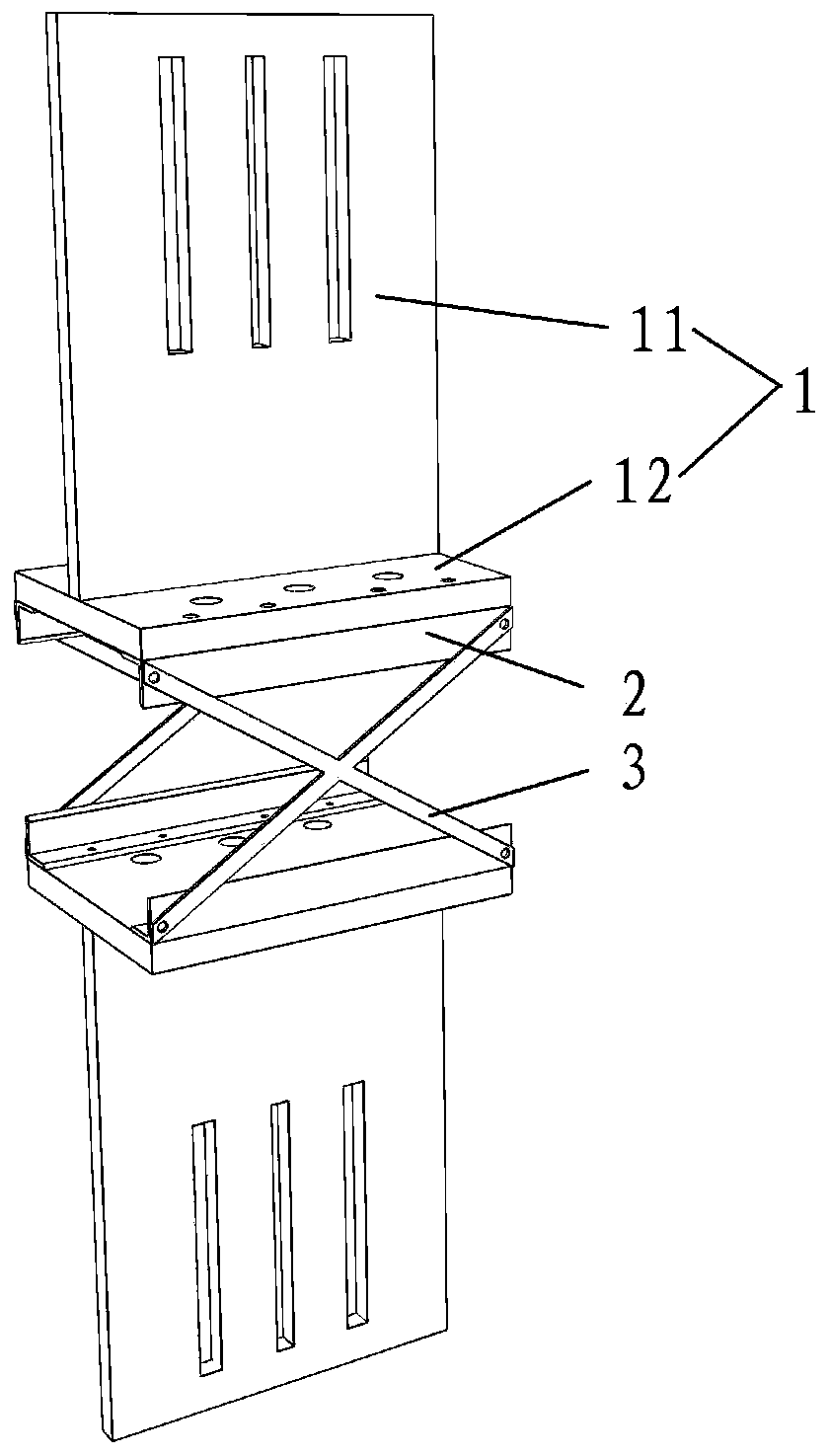

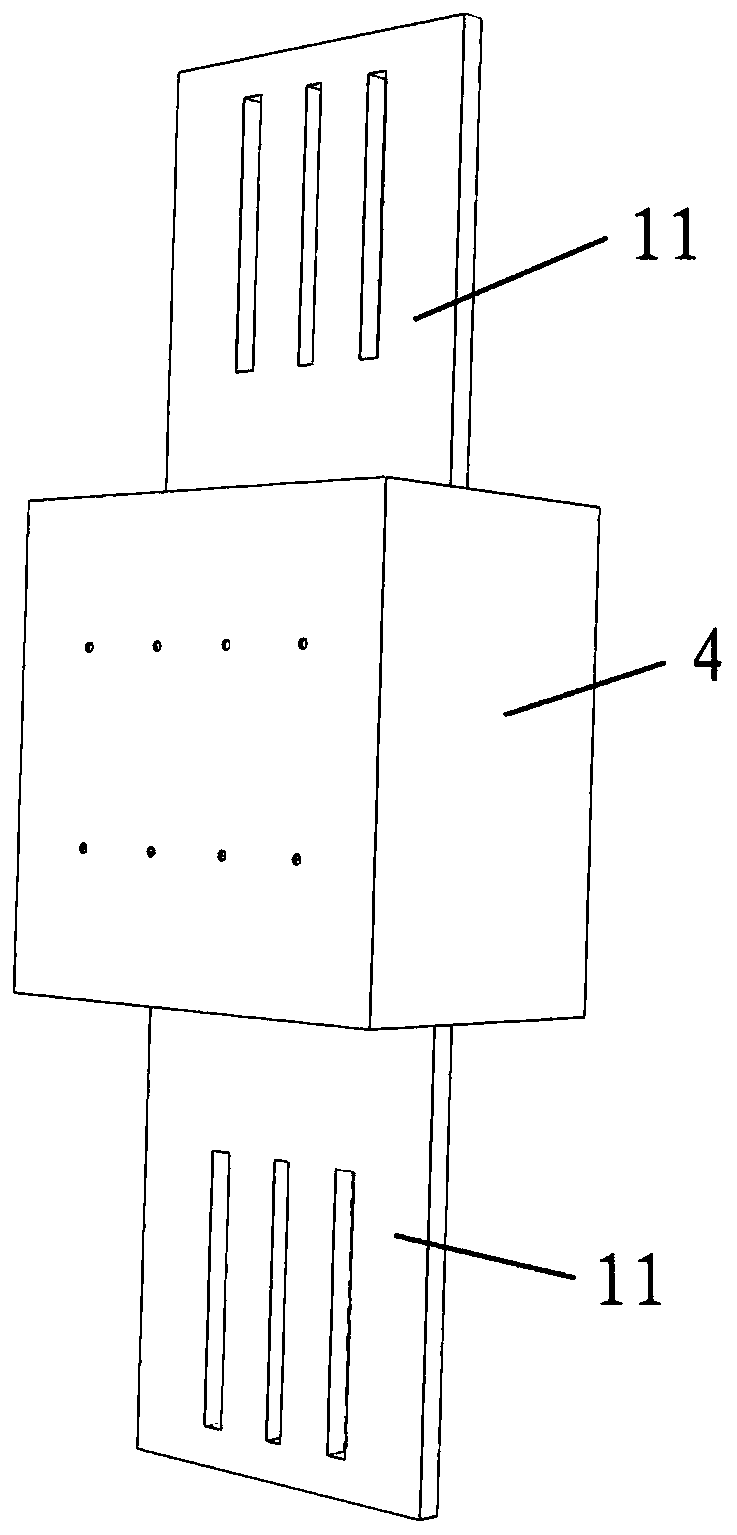

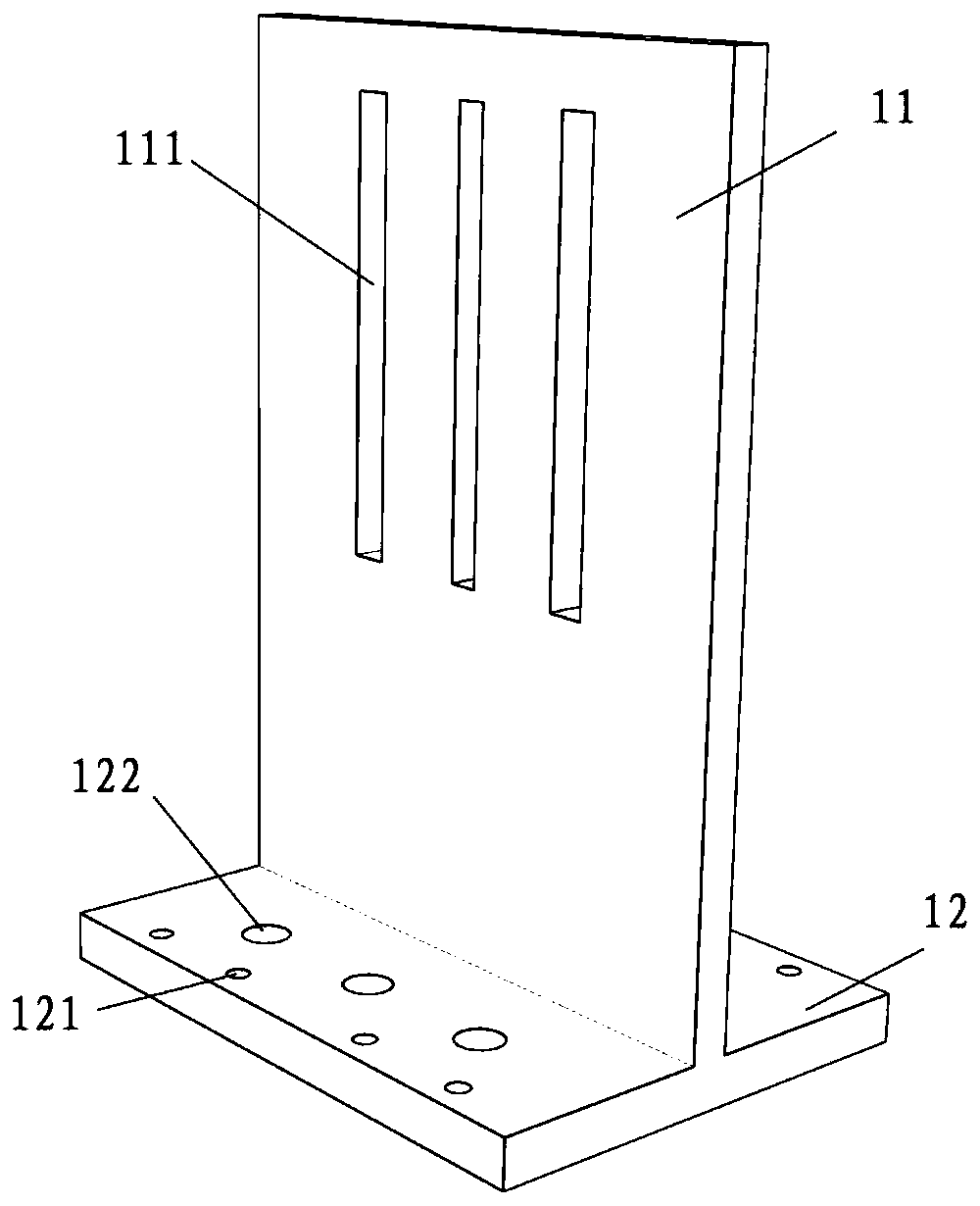

[0060] See attached figure 1 To attach Figure 5 , this embodiment discloses a wall-type connection damper connection member, including: embedded parts 1, angle steel 2, X-shaped clamping plate 3, damper and box-shaped baffle 4 with openings at both ends;

[0061] Embedded parts 1 are a group and arranged symmetrically, which all include a fixed plate 11 and an outrigger plate 12; the fixed plate 11 and the outrigger plate 12 are fixed to form a T-shaped structure; two outrigger plates 12 are arranged in parallel;

[0062] Angle steel 2 is two groups, and each group is respectively fixed on the edge of outrigger plate 12, and the position of angle steel 2 on two outrigger plate 12 is corresponding;

[0063] The four ends of the X-shaped clamping plate 3 are respectively fixed on two angle steels 2 on the same side of the outrigger 12;

[0064] The damper is fixed between two outrigger plates 12;

[0065] The inner side of the box-shaped baffle 4 is fixedly connected with th...

Embodiment 2

[0075] See attached figure 1 To attach Figure 6 , the present embodiment discloses a construction method for connecting members of a wall-type connection damper, which specifically includes the following steps:

[0076] S1, preliminarily determine the installation position of the fixing plate 11 in the binding steel bars of the cantilever wall 5, and bind and fix the two fixing plates 11 in the binding steel bars of the cantilever wall 5 at the top and bottom;

[0077] S2, the angle steel 2 is fixedly connected with the overhanging plate 12 through bolts, and the X-type clamping plate 3 is fixedly connected with the angle steel 2 through bolts. After the connection is completed, the fixing plate 11 is welded to the steel bars of the cantilever wall 5, and then formwork is poured. When building the infill wall 6, reserve an operation gap with the cantilever wall 5;

[0078] S3. After the construction of the cantilever wall 5 is completed, the angle steel 2 and the X-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com