A double-axis multi-directional semi-automatic road step laying device with bottoming and transporting

A multi-directional, semi-automatic technology, applied in the field of road paving devices and road construction, can solve problems such as low efficiency and waste of manpower, and achieve the effect of not easy to grasp, suitable for grasping, and saving manual handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

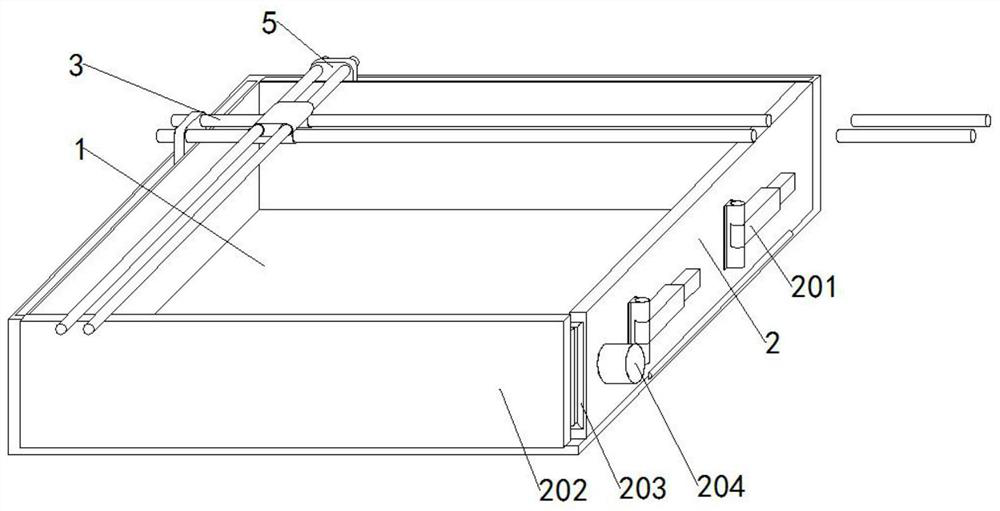

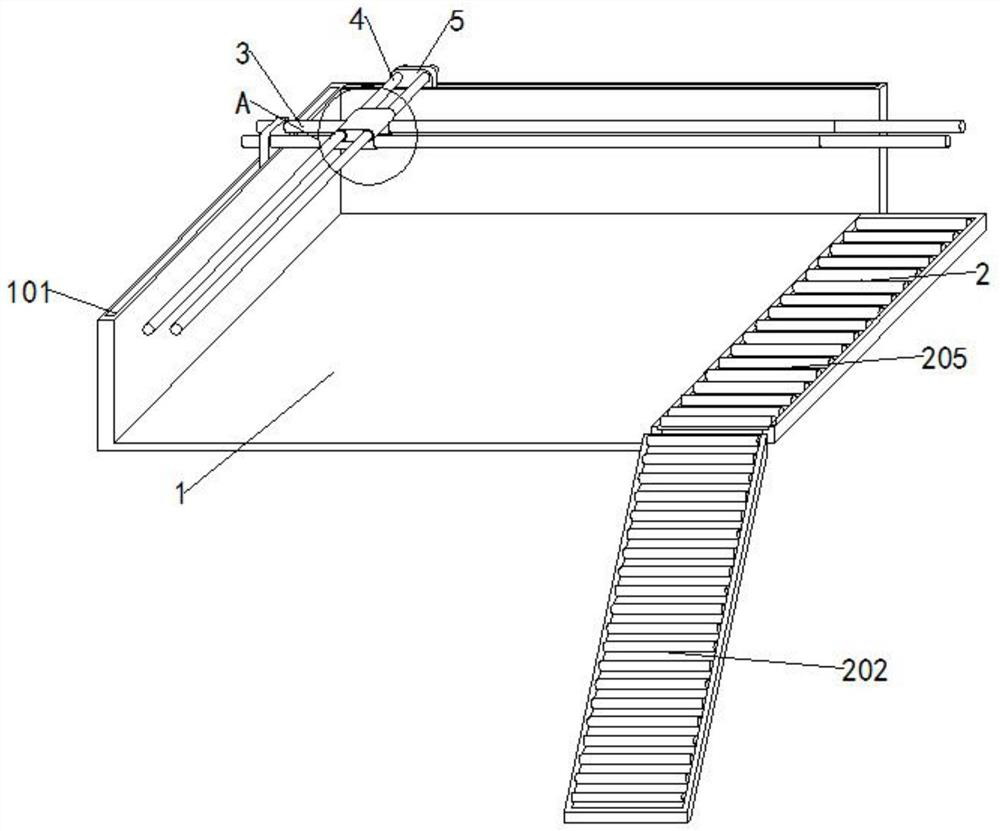

[0027] see Figures 1 to 9, In the embodiment of the present invention, a semi-automatic road step paving device of double-axis and multi-directional bottoming and transporting type includes a placing groove 1, a sliding groove 101, a sliding rod 1011, a sliding path 2, a manual telescopic support rod 201, a tilting Slideway 202, offset gear 203, motor 1 204, small transmission gear 1 2041, large transmission gear 2042, small transmission gear 2 2043, roller 1 205, horizontal bar 3, snap ring 301, vertical bar 4, sliding plate 5. Motor two 501, transmission belt 502, roller two 503, hydraulic rod 6, socket ring 601, socket block 602, sliding hole 6021, contact block 6022, spring one 6023, spring two 6024, fixing rod 603, bracket 604, The rubber plate 605, the threaded fixing rod 606 and the motor 607, the left side and the top of the rear side of the placement slot 1 are nested with the chute 101, the left and right sides of the chute 101 are fixedly connected with the slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com