Plant fiber treatment and preparation method for papermaking

A plant fiber and softening enzyme technology, applied in the field of papermaking, can solve the problems of high cost and lack of fiber affinity, and achieve the effects of improving stability, mild conditions and shortening reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

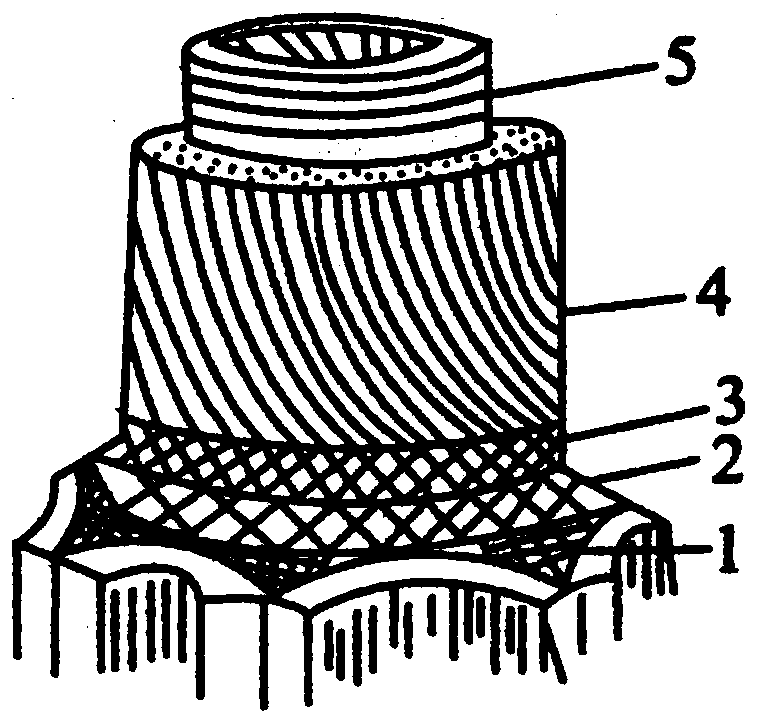

Image

Examples

Embodiment 1

[0032] Step a0, plant fiber opening: placing the wood chips in a grinder, and grinding them until the wood chips with a particle size not greater than 5 cm account for 80% of all the wood chips;

[0033] Step a, softening with plant fiber softening enzyme: mix industrial pancreatin with a concentration of 25U / g and fiber-opened wood chips at a feeding ratio of 100g / t at a temperature of 50°C and a pH value of 9.0, and then add them to the storage In the tank, the reaction time in the storage tank is 2 hours, and the aeration device arranged at the bottom of the storage tank disturbs the softening enzyme, and the aeration rate is 2 times / min;

[0034] Step b, plant fiber purification: add water to the softened plant fiber reacted in the storage tank, centrifuge to obtain the supernatant, concentrate, the concentration temperature is 80°C, repeat the above centrifugation and concentration steps 3 times; the last obtained The supernatant is mixed with ethanol and left to stand to...

Embodiment 2

[0037]Step a0, plant fiber opening: placing the wood chips in a grinder, and grinding them until the wood chips with a particle size not greater than 5 cm account for 80% of all the wood chips;

[0038] Step a, plant fiber softening enzyme softening: mix the microbial protease with a concentration of 25U / g and the fiber-opened wood chips at a feeding ratio of 100g / t at a temperature of 50°C and a pH value of 5.0, and then add them to the storage tank Among them, the reaction time in the storage tank is 2 hours, and the aeration device arranged at the bottom of the storage tank disturbs the softening enzyme, and the aeration rate is 2 times / min;

[0039] Step b, plant fiber purification: add water to the softened plant fiber reacted in the storage tank, centrifuge to obtain the supernatant, concentrate, the concentration temperature is 80°C, repeat the above centrifugation and concentration steps 3 times; the last obtained The supernatant is mixed with ethanol and left to stand...

Embodiment 3

[0042] Step a0, plant fiber opening: placing the wood chips in a grinder, and grinding them until the wood chips with a particle size not greater than 5 cm account for 80% of all the wood chips;

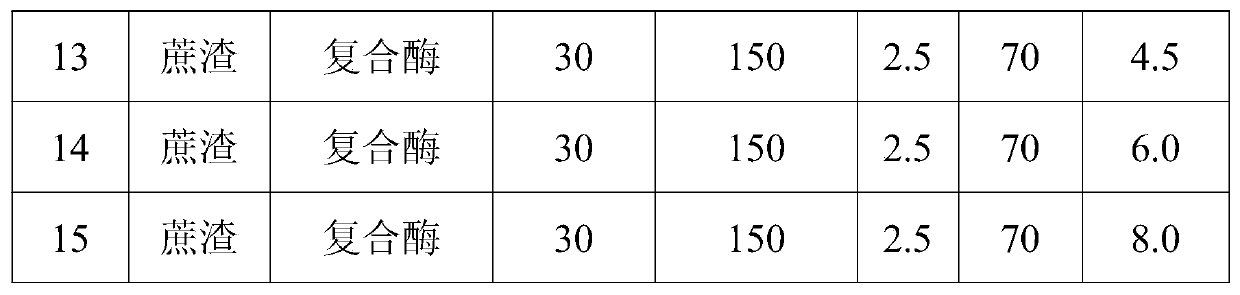

[0043] Step a, plant fiber softening enzyme softening: mix the compound enzyme with a concentration of 25U / g and the fiber-opened wood chips according to the feeding ratio of 100g / t at a temperature of 50°C and a pH value of 6.0, and then add them to the storage tank Among them, the reaction time in the storage tank is 2 hours, and the aeration device arranged at the bottom of the storage tank disturbs the softening enzyme, and the aeration rate is 2 times / min;

[0044] Step b, plant fiber purification: add water to the softened plant fiber reacted in the storage tank, centrifuge to obtain the supernatant, concentrate, the concentration temperature is 80°C, repeat the above centrifugation and concentration steps 3 times; the last obtained The supernatant is mixed with ethanol and lef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com