A kind of universal digital inkjet printing primer and preparation method thereof

A digital inkjet, general-purpose technology, applied in the field of dyeing and finishing, it can solve problems such as poor fluidity and pulp spots, and achieve the effects of low cost, high brightness and easy viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

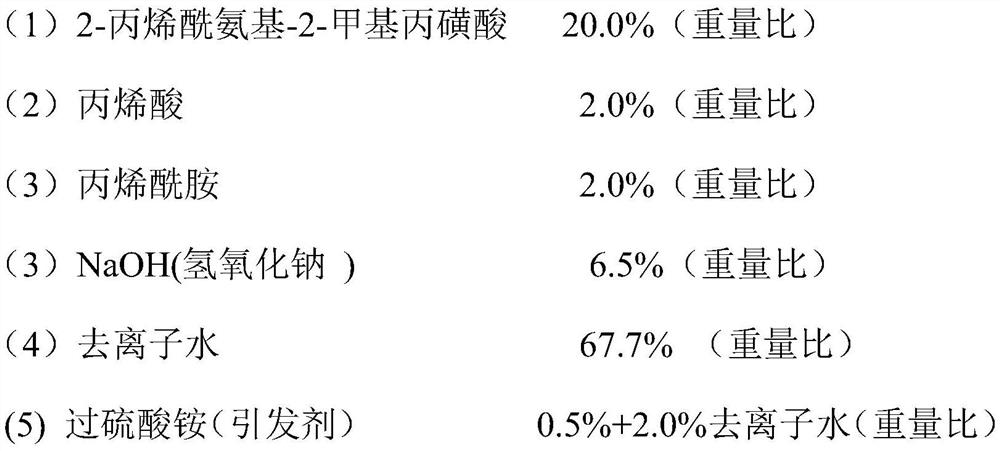

[0019] Production formula:

[0020]

[0021] Detailed production process:

[0022] Add 20.0% of 2-acrylamido-2-methylpropanesulfonic acid, 2.0% of acrylic acid, and 2.0% of acrylamide into a three-necked round-bottomed flask in turn, add 66.7% of deionized water, stir to dissolve, and add to 6.5% NaOH And, adjust the pH to about 6.0, protect it with nitrogen, and slowly raise the temperature to 65°C. At this time, slowly add the initiator ammonium persulfate aqueous solution 0.5% ammonium persulfate + 1.3% deionized water, drop it in 10 minutes, and the reaction system begins to occur Polymerization reaction releases heat, the temperature of the reaction system rises, the heating is stopped, and after the temperature drops to a constant temperature of 70°C, the reaction is heated and kept for 2.0 hours, and the product is cooled to room temperature to obtain a light yellow transparent viscous liquid.

Embodiment 2

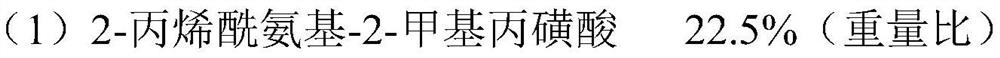

[0024] Production formula:

[0025]

[0026]

[0027] Detailed production process:

[0028] Add 22.5% of 2-acrylamido-2-methylpropanesulfonic acid, 3.0% of acrylic acid, and 3.0% of acrylamide into a three-necked round-bottomed flask in turn, add 61.95% of deionized water, stir to dissolve, and add to 7.5% NaOH And, adjust the pH to about 6.5, protect it with nitrogen, and slowly raise the temperature to 70°C. At this time, slowly add the initiator ammonium persulfate aqueous solution 0.75% ammonium persulfate + 1.3% deionized water, drop it in 15 minutes, and the reaction system begins to occur Polymerization reaction releases heat, the temperature of the reaction system rises, the heating is stopped, and after the temperature drops to a constant temperature of 75°C, the reaction is heated and kept for 3.0 hours, and the product is cooled to room temperature to obtain a light yellow transparent viscous liquid.

Embodiment 3

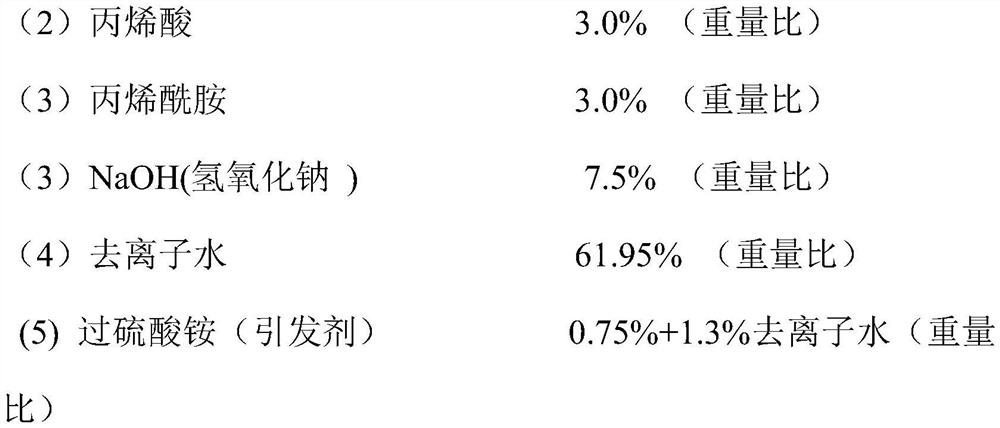

[0030] Production formula:

[0031]

[0032] Detailed production process:

[0033] Add 25.0% of 2-acrylamido-2-methylpropanesulfonic acid, 4.0% of acrylic acid and 4.0% of acrylamide into a three-necked round-bottomed flask in turn, add 51.7% of deionized water, stir to dissolve, and add to 9.0% NaOH And, adjust the pH to about 7.0, protect it with nitrogen, and slowly raise the temperature to 75°C. At this time, slowly add the initiator ammonium persulfate aqueous solution 1.0% ammonium persulfate + 1.3% deionized water, drop it in 20 minutes, and the reaction system begins to occur Polymerization reaction releases heat, the temperature of the reaction system rises, and the heating is stopped. After the temperature drops to a constant temperature of 75°C, the reaction is heated and kept for 4.0 hours, and the product is cooled to room temperature to obtain a light yellow transparent viscous liquid.

[0034] application:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com