Preparation method of formaldehyde-free washing-resistant flame-retardant fabric

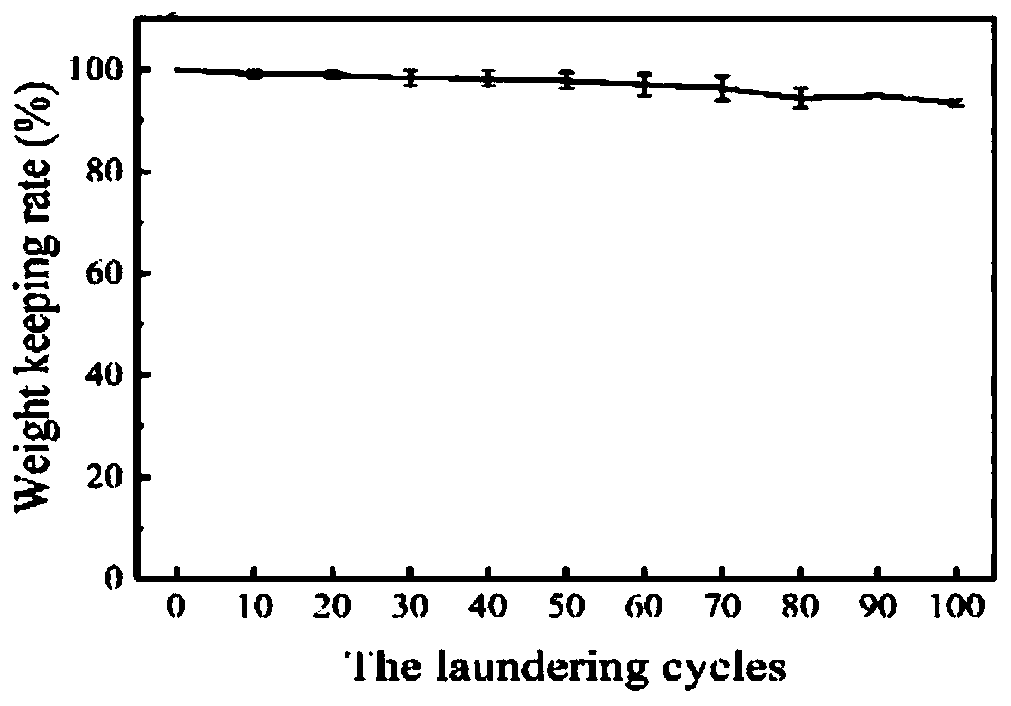

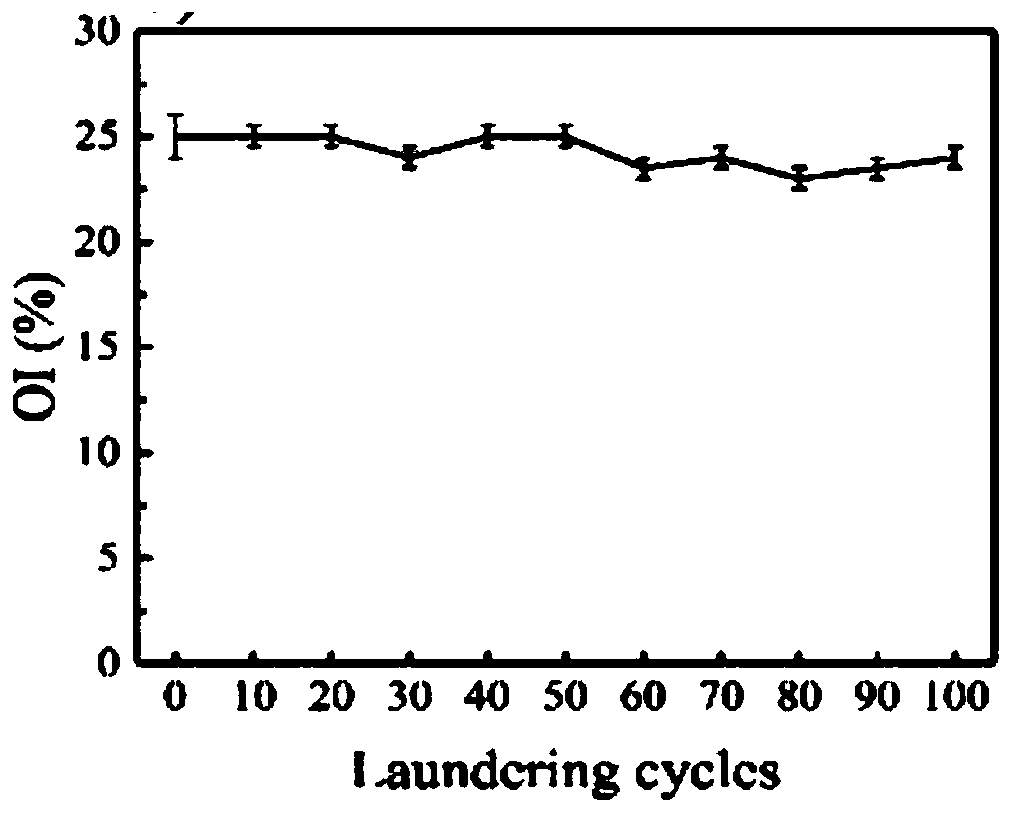

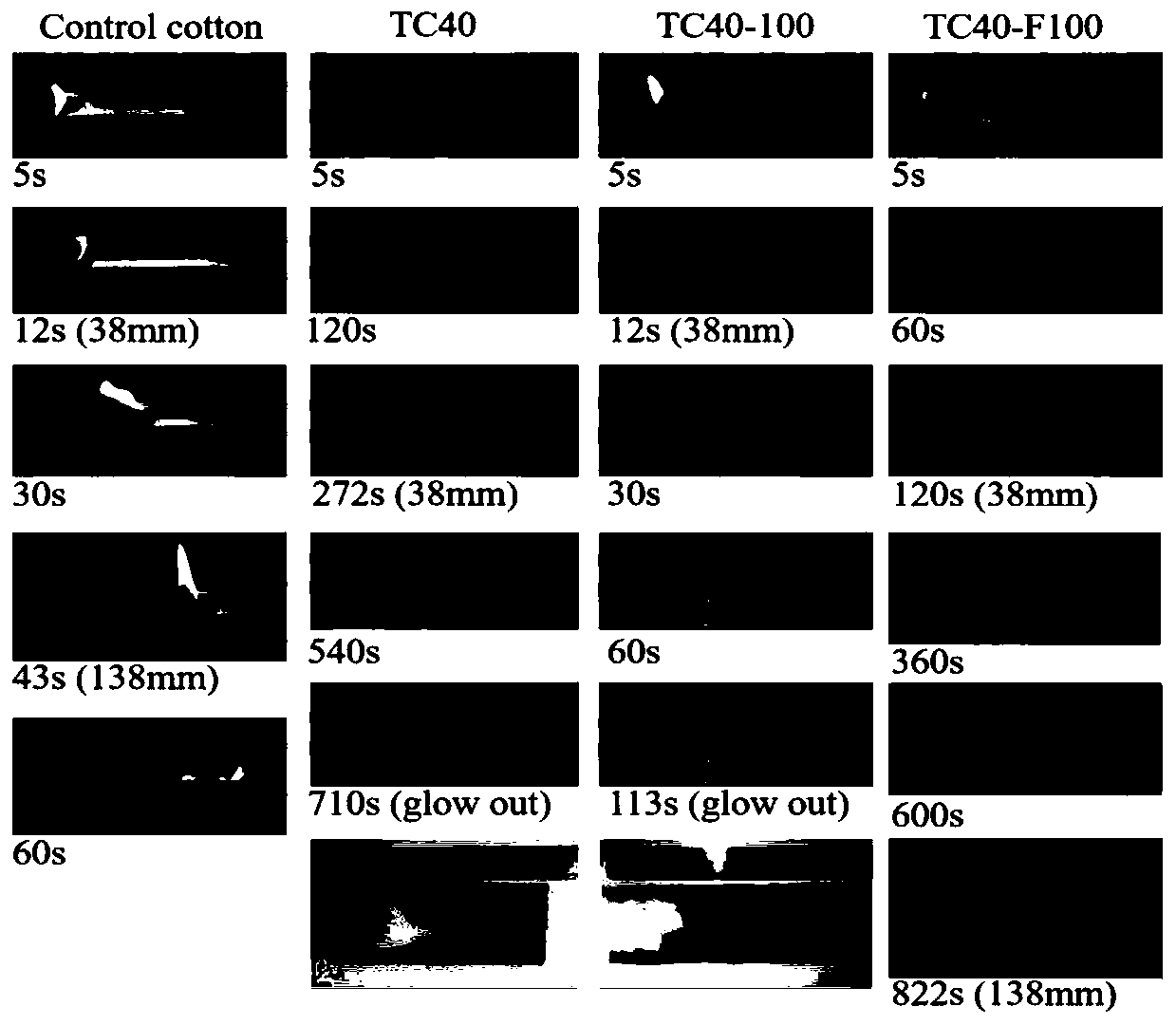

A flame retardant fabric, washable technology, applied in the direction of flame retardant fibers, plant fibers, animal fibers, etc., can solve problems such as poisoning formaldehyde, and achieve excellent flame retardant performance, excellent washing resistance, and obvious flame retardant effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1. Dissolve an aqueous solution of catechin with a mass concentration of 1% at 30°C, immerse the cotton fabric in this solution, stir and heat at 30°C for 3 hours, the bath ratio is 1:10, take out the cotton fabric and dry it at 50°C 3h;

[0037] Step 2, dissolving a chitosan solution with a mass concentration of 1% at 20°C, stirring and heating the cotton fabric in step 1 with 98°C in this solution for 18min, the bath ratio is 1:50, taking out the cotton fabric and using water Rinse for 1min, then dry at 90°C for 0.5h;

[0038] Step 3: Dissolve calcium acetate solution with a mass concentration of 6% at 60°C, stir and heat the cotton fabric treated in step 2 in this solution at 50°C for 60min, the bath ratio is 1:50, take out the cotton fabric and rinse it with water 5min, and then dried at 50°C for 3h to obtain a washable flame-retardant cotton fabric.

Embodiment 2

[0040] Step 1. Dissolve catechin aqueous solution with a mass concentration of 10% at 60°C, immerse the cotton fabric in this solution and stir and heat at 90°C for 1 hour, the bath ratio is 1:20, take out the cotton fabric and dry it at 60°C 1.5h;

[0041] Step 2, dissolving a chitosan solution with a mass concentration of 2% at 60°C, stirring and heating the cotton fabric in step 1 with 75°C in this solution for 45min, the bath ratio is 1:20, taking out the cotton fabric and using water Rinse for 3 minutes, then dry at 60°C for 1.5 hours;

[0042] Step 3. Dissolve a magnesium nitrate solution with a mass concentration of 10% at 25°C. Stir and heat the cotton fabric treated in step 2 in this solution at 90°C for 1 hour, with a bath ratio of 1:20. Take out the cotton fabric and rinse it with water 3min, and then dried at 60°C for 1.5h to obtain a washable flame-retardant cotton fabric.

Embodiment 3

[0044] Step 1, dissolving a chitosan solution with a mass concentration of 7% at 20°C, stirring and heating the cotton fabric at 60°C for 30 minutes in this solution, with a bath ratio of 1:25, taking out the cotton fabric and rinsing it with water for 5 minutes, and then Dry at 70°C for 1.5h;

[0045] Step 2. Dissolve an aqueous catechin solution with a mass concentration of 10% at 50°C, soak the cotton fabric treated in step 1 in this solution and stir and heat at 80°C for 45min, the bath ratio is 1:25, and take out the cotton fabric Dry at 70°C for 1.5h;

[0046] Step 3. Dissolve calcium acetate solution with a mass concentration of 5% at 30°C. Stir and heat the cotton fabric treated in step 2 in this solution at 90°C for 1 hour with a bath ratio of 1:20. Take out the cotton fabric and rinse it with water 3min, and then dried at 60°C for 2h to obtain a washable flame-retardant cotton fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peak heat release rate | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com