Preparation method of vanadium-doped double-layer nickel oxide electrochromic film

An electrochromic and nickel oxide technology, used in coatings, optics, instruments, etc., can solve problems such as poor stability, and achieve the effects of ensuring stability, increasing speed, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

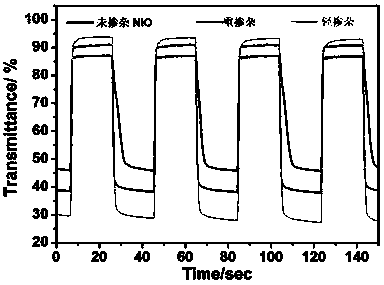

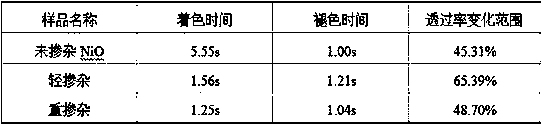

[0017] Specific embodiment one: the present invention utilizes magnetron sputtering method to prepare the method for double-layer nickel oxide electrochromic thin film is to realize according to the following steps:

[0018] 1. Ultrasonic clean the glass substrate covered with ITO in trichlorethylene, acetone, and ethanol for 5-10 minutes to remove the dust and grease covered on the surface, and then use deionized water to clean the substrate to remove the residual ethanol , and finally blow dry with nitrogen to obtain a clean ITO substrate.

[0019] 2. The present invention adopts radio frequency reaction co-sputtering method to prepare crystalline nickel oxide film, and the target material used is metallic nickel with a purity of 99.99%. Use the clean ITO substrate obtained in the previous step as the substrate. First vacuumize the vacuum chamber, when the pressure in the chamber reaches 4×10 -4 When Pa is below, turn on the heater to heat the substrate, and start to fill ...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment is different from Embodiment 1 in that: the ITO glass described in step 1 is replaced by FTO glass. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the temperature of the substrate during pre-growth is 200°C-400°C. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com