Acrylonitrile-containing fermentation wastewater treatment process

A technology for fermented wastewater and treatment process, which is applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc. It can solve the problems of low aerobic biochemical efficiency and difficult treatment of fermented wastewater, and achieve the goal of avoiding biochemical efficiency Impact, efficient operation, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

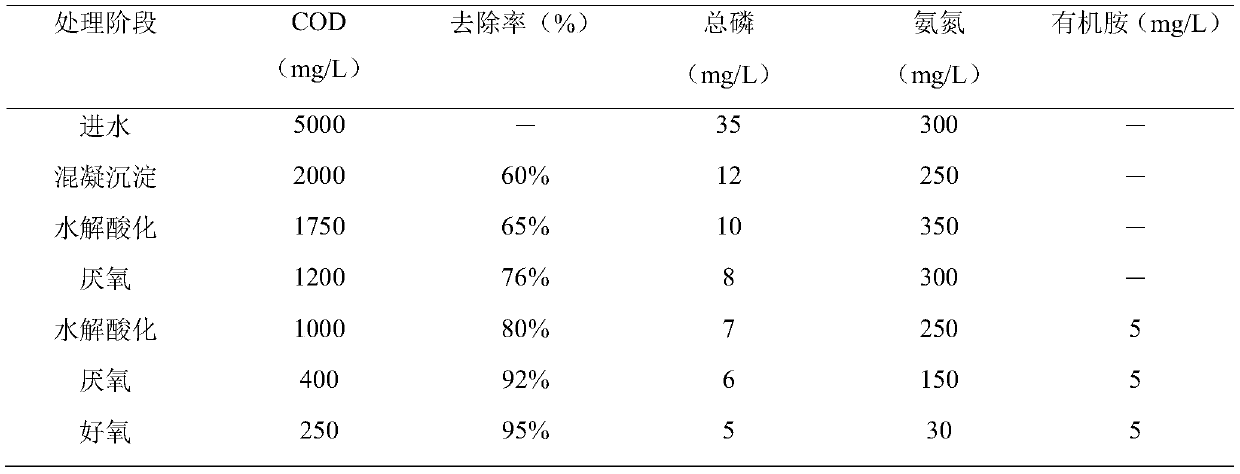

Embodiment 1

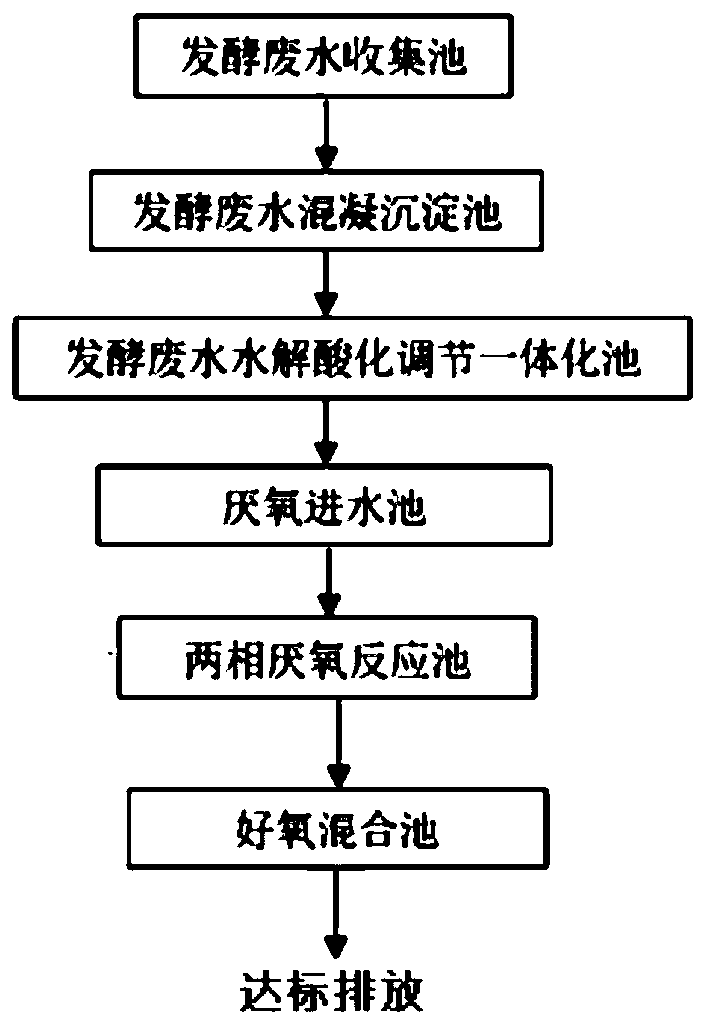

[0034] The water quality indicators of the wastewater in this embodiment are as follows: the COD concentration in the wastewater is 5000 mg / L, the ammonia nitrogen concentration is 300 mg / L, the total phosphorus concentration is 35 mg / L, the acrylonitrile concentration is 2000 mg / L, and the pH value is about 7. figure 1 Be the flow chart of process of the present invention, as figure 1 As shown, the specific processing steps are as follows:

[0035] 1) First, add the wastewater to calcium hydroxide solution for coagulation and precipitation, the suspended solids are reduced to 250mg / L, and the COD is reduced to 2000mg / L. The ORP of the reactor is 30mv; the hydraulic retention time is controlled at 8h.

[0036] 2) Treat the wastewater treated in step 1) in an anaerobic reactor, control the ORP of the reactor in the treatment stage to be -100mv, and control the hydraulic retention time to 16h.

[0037]3) The waste water treated in step 2) is treated in a two-phase anaerobic re...

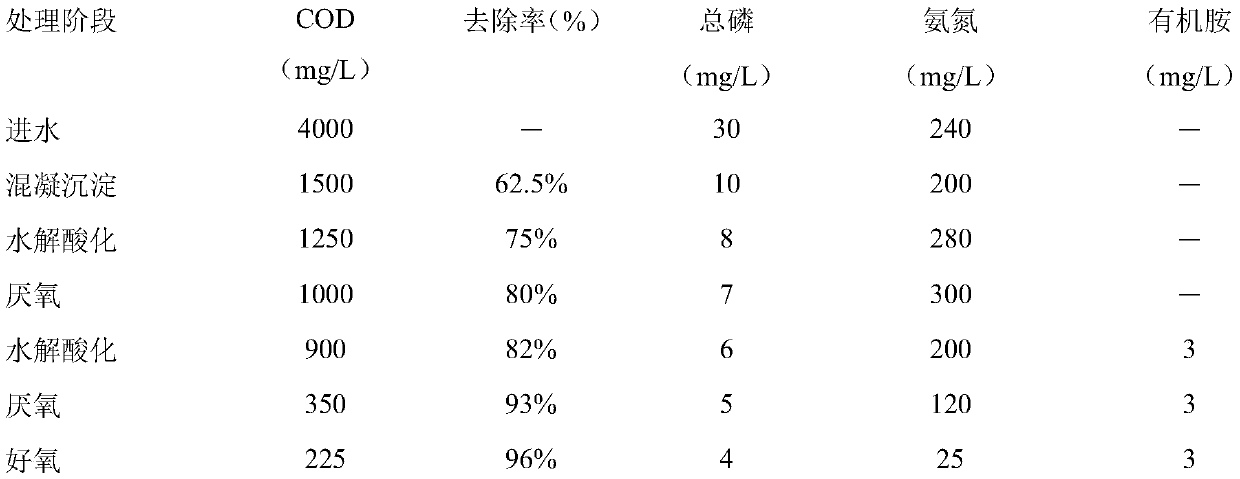

Embodiment 2

[0043] The wastewater quality indicators of this embodiment are as follows. The COD concentration in the wastewater is 4000 mg / L, the ammonia nitrogen concentration is 240 mg / L, the total phosphorus concentration is 30 mg / L, the acrylonitrile concentration is 1600 mg / L, and the pH value is about 7.

[0044] The specific steps of the treatment process of this wastewater in the present embodiment are as follows:

[0045] 1) First, add ferrous sulfate to the wastewater for coagulation and precipitation, reduce the concentration of suspended solids to 200mg / L, and reduce the concentration of COD to 1500mg / L, export the supernatant after coagulation and precipitation for hydrolysis and acidification treatment, and control the hydrolysis in the treatment stage The ORP of the acidification reactor is 50mv, and the hydraulic retention time is controlled at 4h.

[0046] 2) Treating the wastewater treated in step 1) in an anaerobic reactor, controlling the ORP of the reactor in the trea...

Embodiment 3

[0052] The wastewater quality indicators of this embodiment are as follows. The COD concentration in the wastewater is 4500 mg / L, the ammonia nitrogen concentration is 250 mg / L, the total phosphorus concentration is 25 mg / L, the acrylonitrile concentration is 1700 mg / L, and the pH value is about 7.

[0053] The specific steps of the treatment process of this wastewater in the present embodiment are as follows:

[0054] 1) First, add polyferron to the wastewater for coagulation and precipitation, the concentration of suspended solids is reduced to 180mg / L, and the concentration of COD is reduced to 1700mg / L, and the supernatant after coagulation and precipitation is exported for hydrolysis and acidification treatment, and the hydrolysis and acidification in the treatment stage is controlled The ORP of the reactor is -50mv; the hydraulic retention time is controlled at 5h.

[0055] 2) Treat the wastewater treated in step 1) in an anaerobic reactor, control the ORP of the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com