Steel wire carcass passenger tire bead structure

A technology of tires and steel wires, which is applied to tire parts, tire edges, tire sidewalls, etc., can solve problems such as tire gaps and increase the difficulty of steel wire springback, so as to improve performance, overcome stress concentration, The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

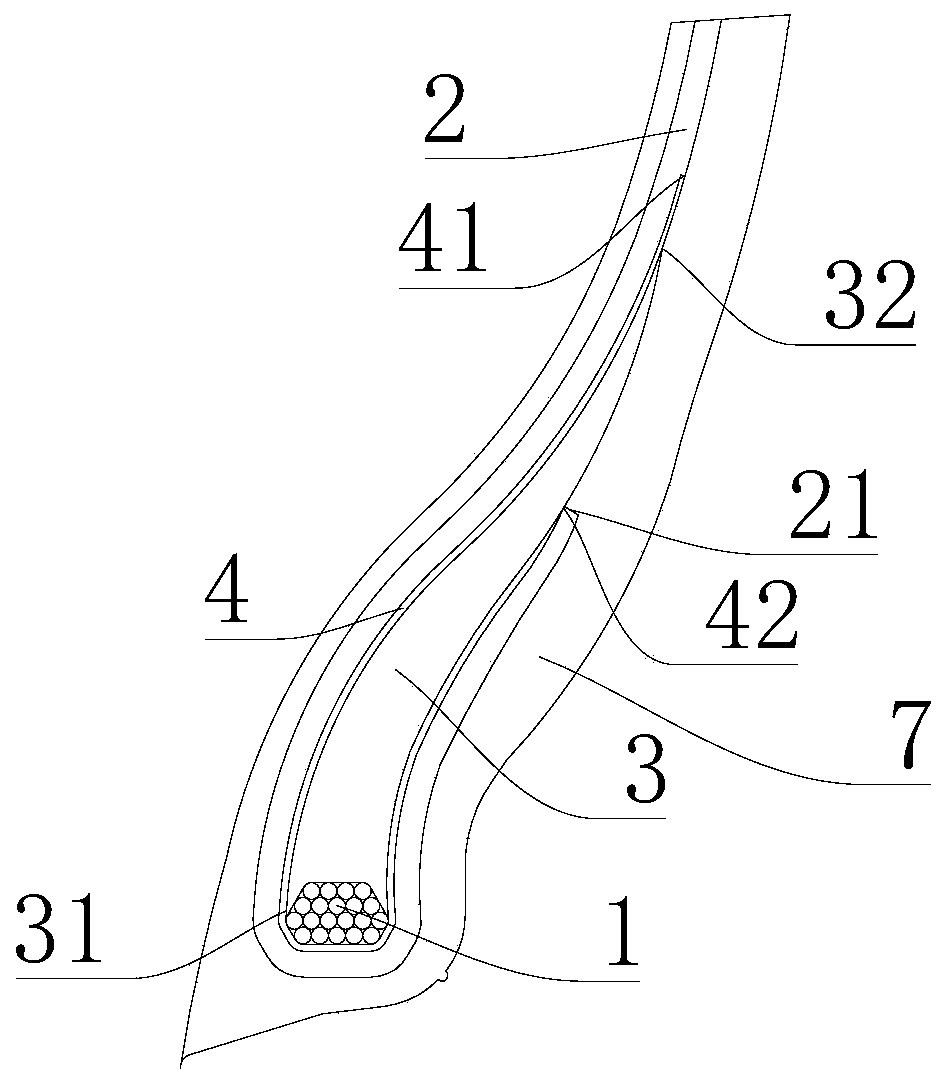

[0031] Embodiment 1: as figure 1 As shown, the present invention provides a steel wire carcass passenger tire rim structure, comprising a bead 1 and a steel wire carcass ply 2, the circumference of the bead 1 is coated with an apex 3, and the apex 3 is formed from the apex The lower end point 31 extends radially to the upper end point 32 of the apex rubber. The steel wire carcass ply 2 bypasses the bottom of the traveler 1 and turns over to the sidewall 7, and then extends radially to the steel wire carcass turn-up end point 21. The steel wire carcass ply 2 and the apex 3 are provided with a thickening film 4, and the end point 21 of the steel wire carcass turn-up is connected with the apex 3 through the thickening film 4. When steel wire is used as a carcass material, it has the problems of high bending rigidity and high resilience. At the same time, there is a problem of poor viscosity between the steel wire carcass ply 2 and the bead ring 1, which may easily cause the spigo...

Embodiment 2

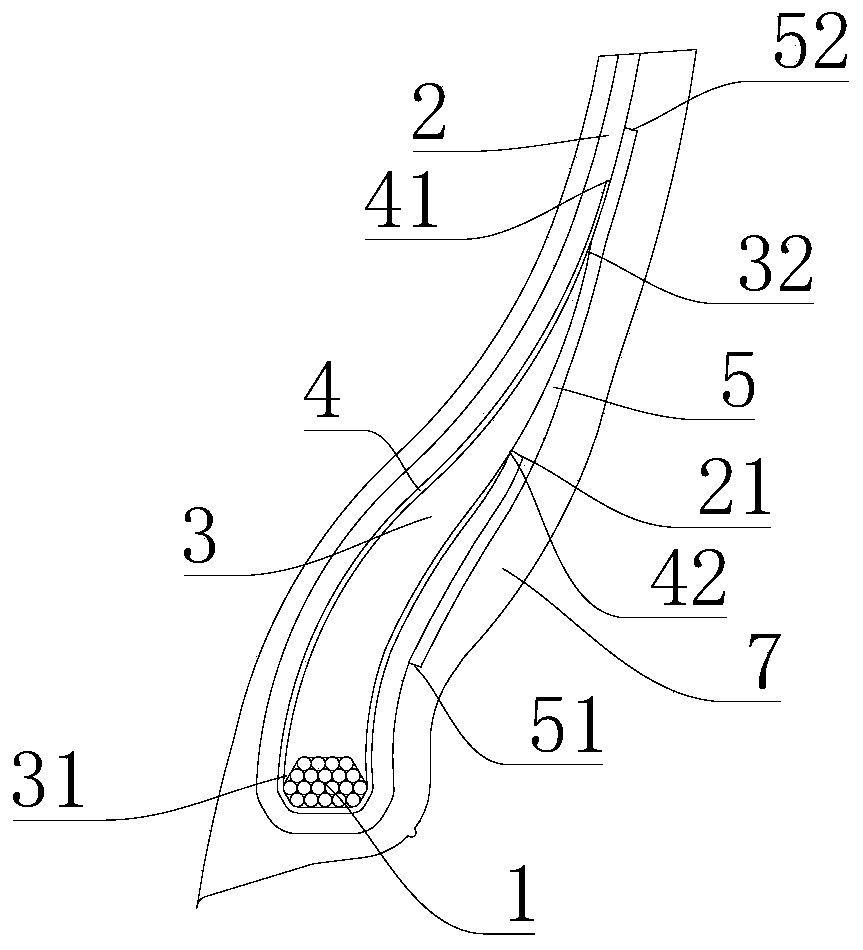

[0035] Embodiment 2: as image 3 As shown, the present embodiment provides a steel wire carcass passenger tire slit structure, the radial height of the upper end point 32 of the apex rubber is higher than the radial height of the turn-up end point 21 of the steel wire carcass, and the upper end point 32 of the apex rubber is in contact with the steel wire The radial distance of the carcass turn-up end point 21 is greater than 10 mm, and the thickness of the apex 3 connected to the steel wire carcass turn-up end point 21 is not less than 2 mm. Considering that the steel wire carcass turn-up end point 21 has a large transverse shear force, the thickness of the apex 3 at the junction of the apex upper end point 32, the steel wire carcass turn-up end point 21 and the steel wire carcass turn-up end point 21 has been tested in this embodiment. Limitation avoids the cutting of the inner rubber material under the action of stress and strain. The above design ensures that the steel wi...

Embodiment 3

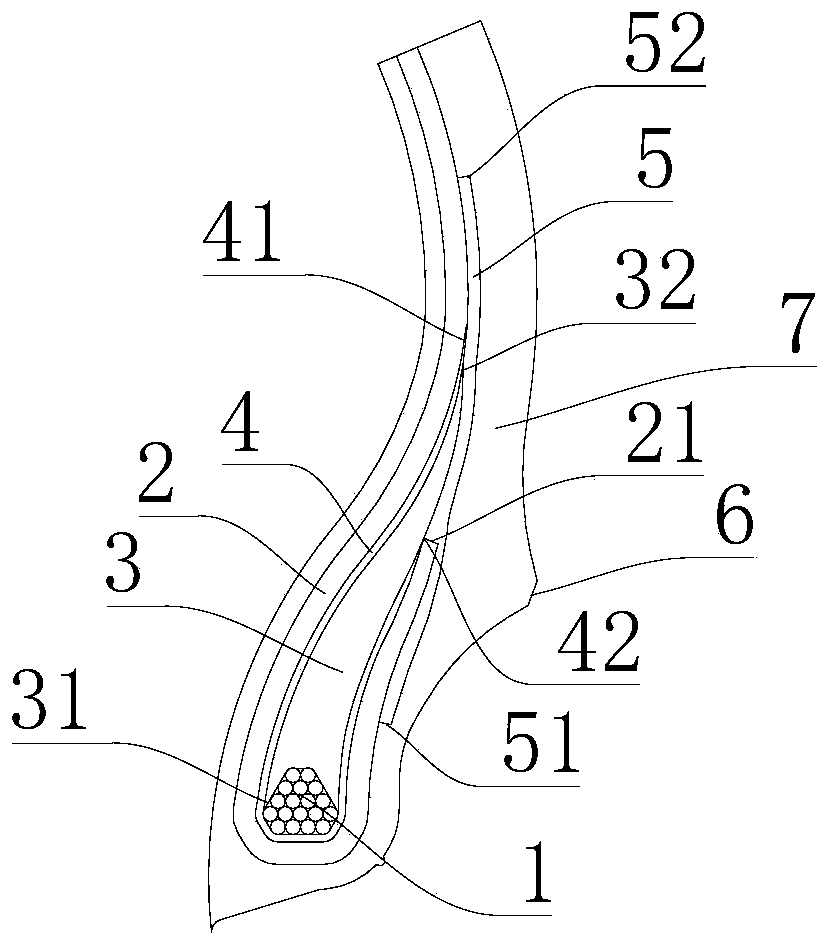

[0038] Embodiment 3: as Figure 4 As shown, the present embodiment provides another steel wire carcass passenger tire slit structure, the radial height of the upper end point 32 of the apex rubber is lower than the radial height of the turn-up end point 21 of the steel wire carcass, and the upper end point 32 of the apex rubber and The radial distance of the turn-up end point 21 of the steel wire carcass is greater than 10 mm. Considering the large transverse shear force at the end point 21 of the steel wire carcass turn-up, this embodiment limits the upper end point 32 of the apex rubber and the turn-up end point 21 of the steel wire carcass, so as to avoid the cutting of the inner rubber material under the action of stress and strain. Through the above design, it is ensured that the inner side of the steel wire carcass turn-up end point 21 is the apex 3, and the outer side is the compound point of the wear-resistant rubber and the sidewall 7 rubber. The transition from hard ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com