Automatic overturning, welding and dispensing machine and automatic overturning, welding and dispensing process

An automatic flipping and welding point technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor effect, low efficiency, and inconformity with mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

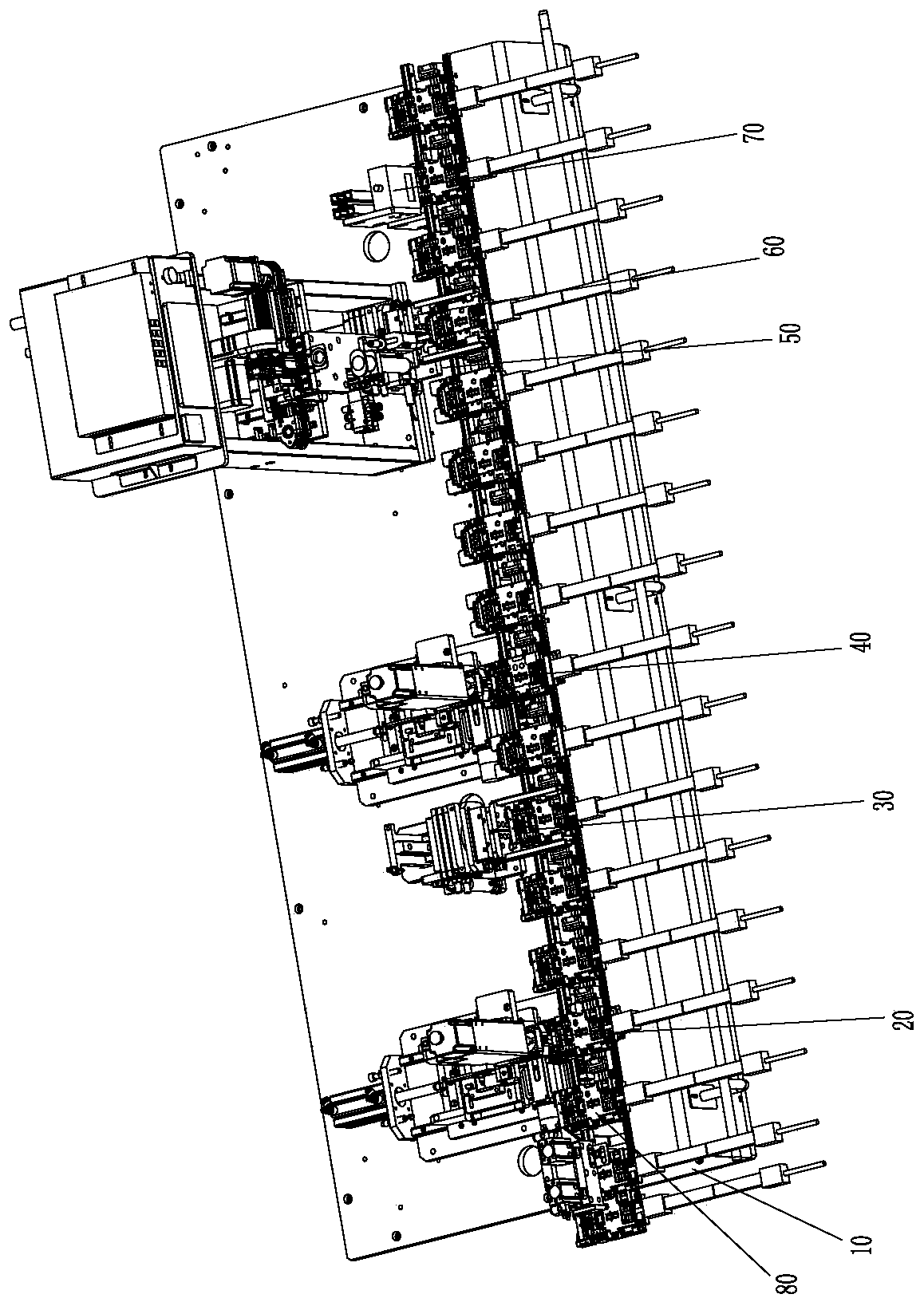

[0038] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the embodiment of the present invention.

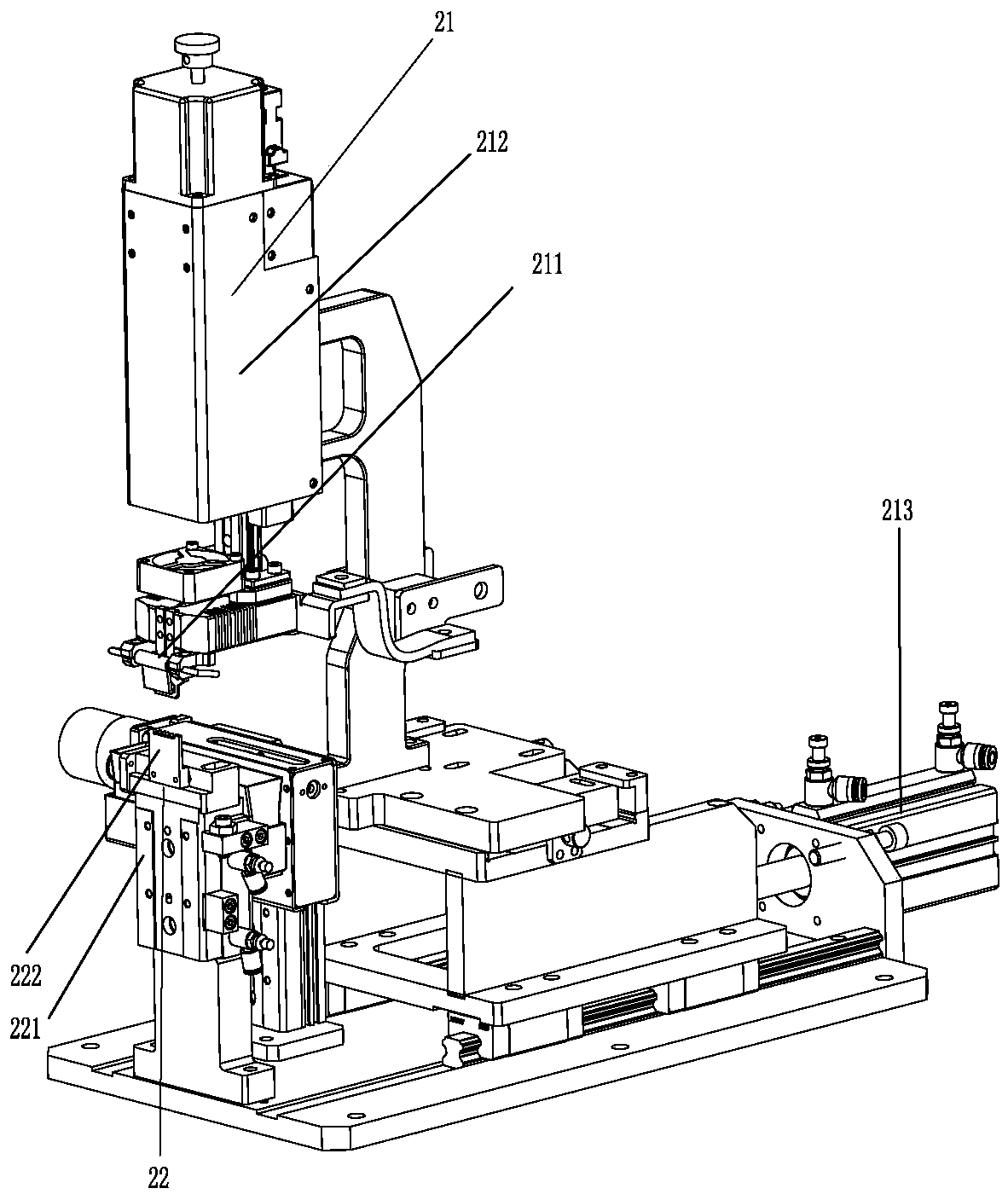

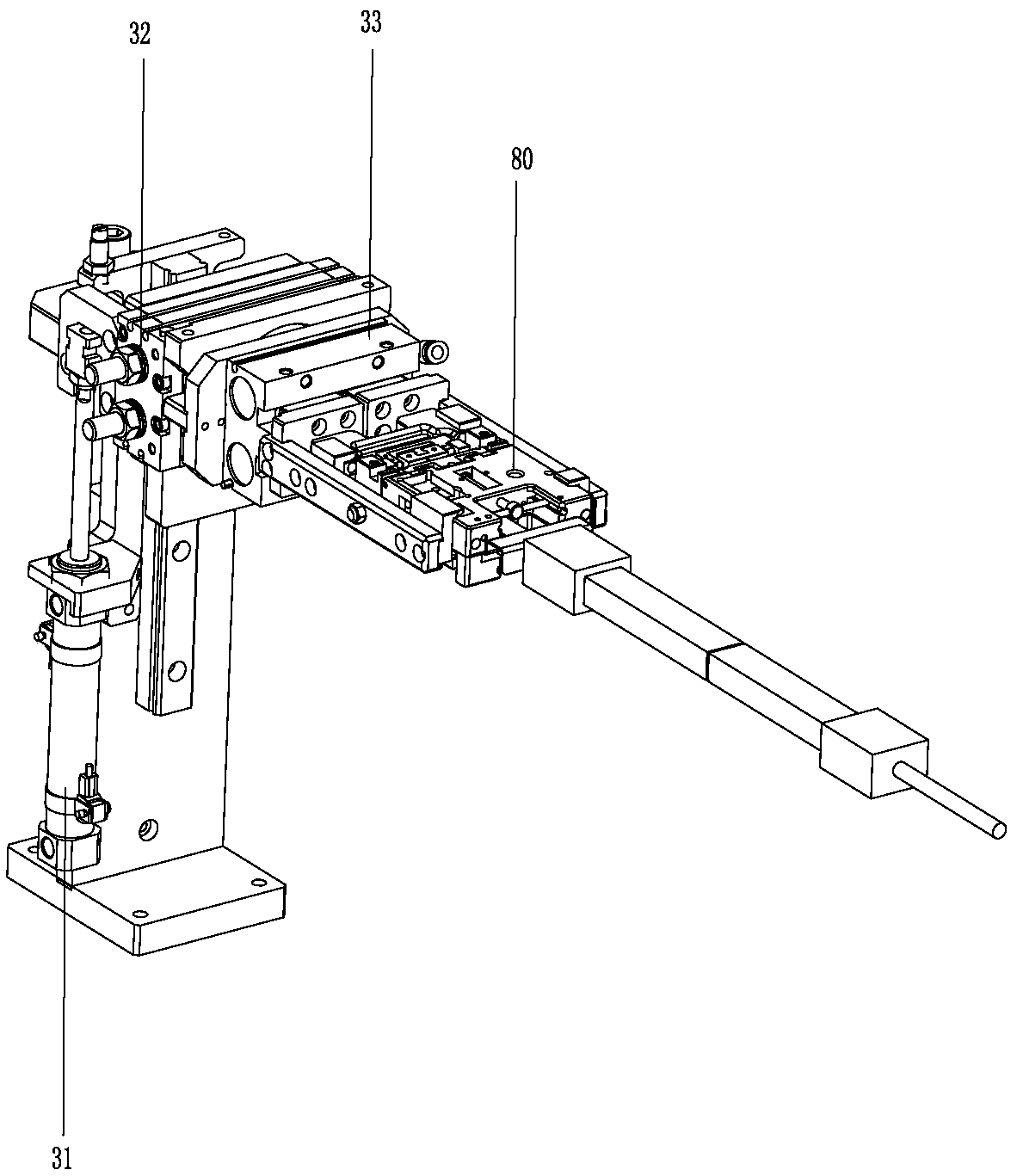

[0039] Such as figure 1 As shown, an automatic flip welding and dispensing all-in-one machine includes a frame 10, the frame 10 is provided with a fixture conveying flow channel, and a front welding station, a first treatment station, and a first welding station are sequentially arranged along the extending direction of the fixture conveying flow path. Tool turning station, reverse welding station, glue dispensing station and double-sided curing station; the workpiece is installed on the clamping jig 80, and the clamping jig 80 passes through all the stations in turn through the runner claw. Generally, the workpiece may refer to a PCB board or a connector that needs to be soldered on both sides. The front welding station is equipped with a front welding module 20, the first jig turning station is equipped with a first jig turning module 30, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com