Intelligent horizontal screw machine operation control system and method

A technology of operation control and decanter, which is applied to centrifuges and centrifuges with rotating drums, etc., which can solve the problems of disassembly inspection, intelligence, low degree of automation, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

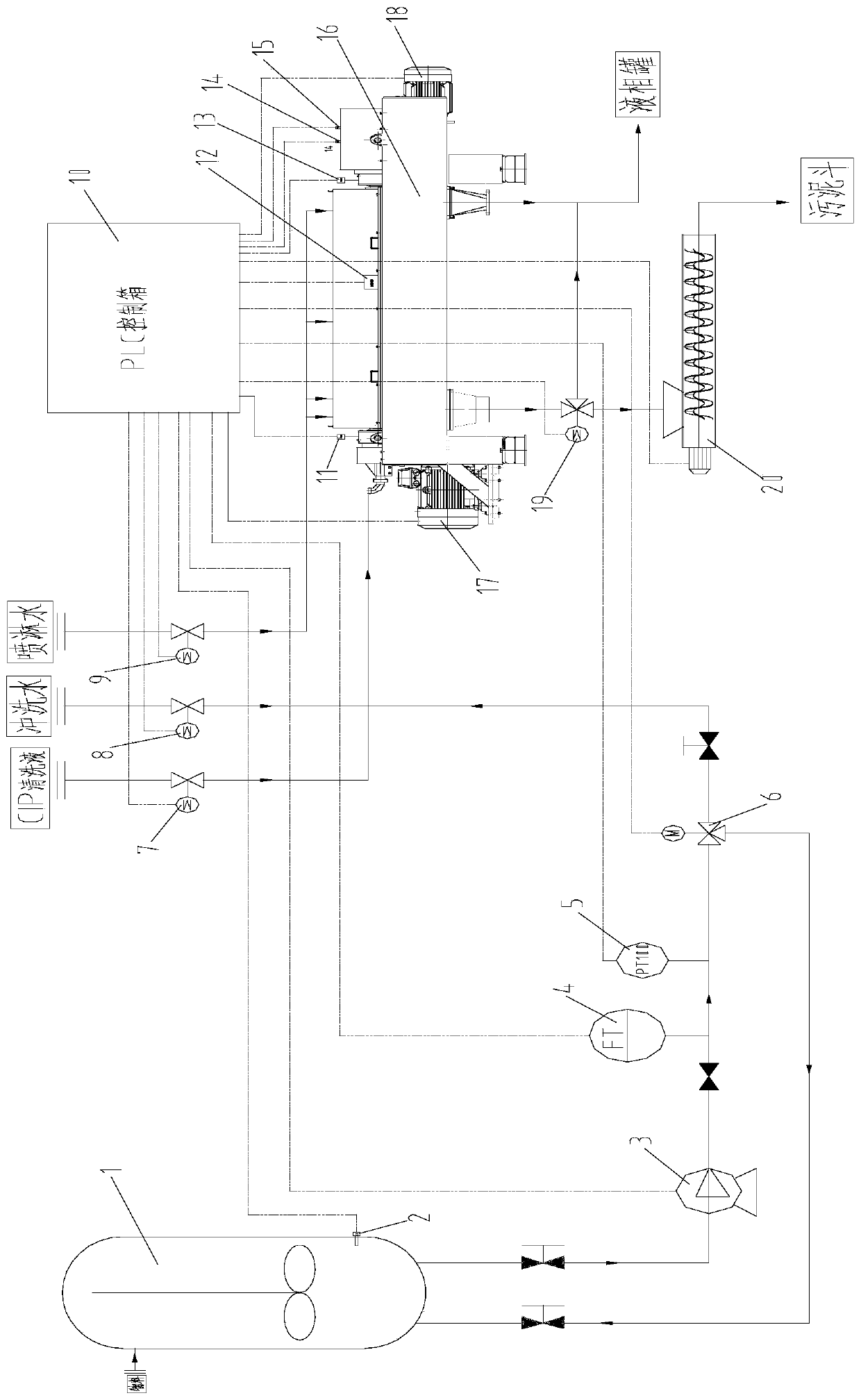

[0028] This embodiment provides an intelligent decanter operation control system, the structure of which is as follows figure 1 As shown, it includes a PLC control box 10, and the motor, liquid level sensor 2, feed pump 3, flow meter 4, first temperature sensor 5, electric three-way valve 6, CIP of the stirring tank 1 connected to the PLC control box 10 Cleaning fluid solenoid valve 7, flushing water solenoid valve 8, spray water solenoid valve 9, second temperature sensor 11, vibration sensor 12, third temperature sensor 13, first rotational speed sensor 14, second rotational speed sensor 15, main motor 17 , Auxiliary motor 18, electric knife gate valve 19 and motor of screw conveyor 20. The main motor 17 is installed at one end of the decanter 16, and the output shaft of the main motor 17 is connected to the drum of the decanter 16 (the main motor drives the decanter drum), and the auxiliary motor 18 is installed on the other side of the decanter 16. One end, and the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com