Intelligent analyzing and monitoring system for load and temperature rise of generatrix groove

An intelligent analysis and monitoring system technology, applied in the control/adjustment system, simultaneously controlling multiple variables, instruments, etc., can solve problems such as power supply system accidents, increased contact point temperature rise, overheating faults, etc., to improve safety and reliability , Easy to use and operate, reasonable structure and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

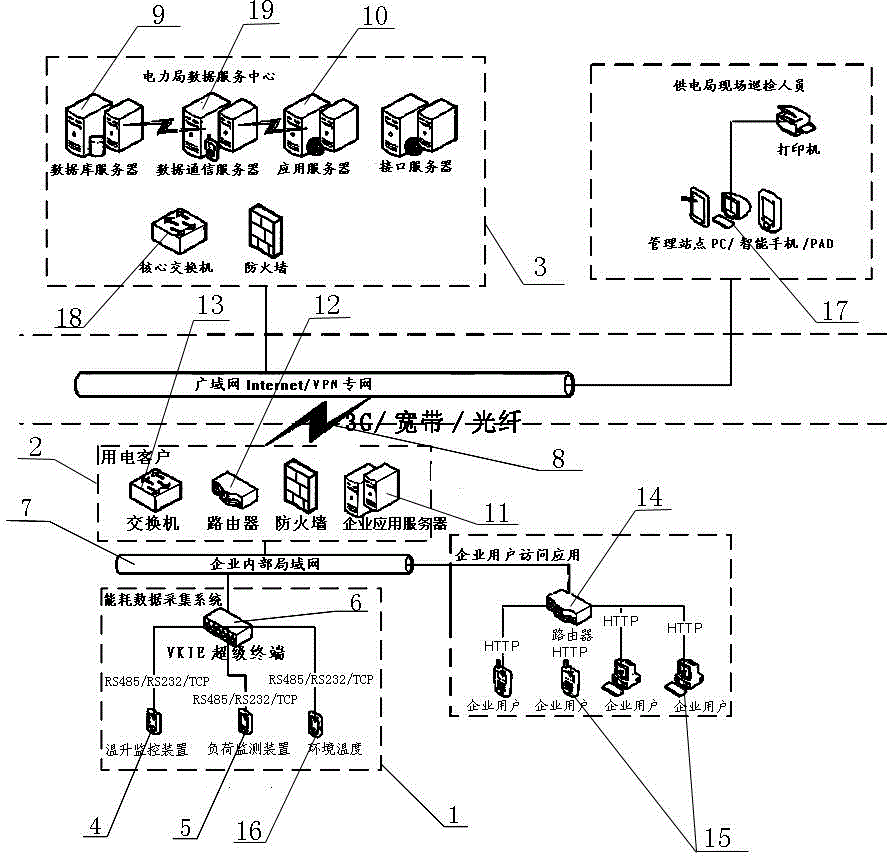

[0013] The functional architecture of the system described in the present invention can be mainly divided into two major systems: the power supply bureau platform and the user single-site platform; the power supply bureau platform is further divided into three parts: data supervision, real-time monitoring, and GIS monitoring, and the user single-site platform provides energy consumption Real-time monitoring and energy comprehensive analysis and other functions.

[0014] The data collection layer adopts meters that meet relevant standards to collect temperature and load energy consumption. And store the real-time data in the real-time database; analyze the energy consumption data in real time through the core trial calculation engine, complete real-time statistical analysis and calculation based on various energy consumption statistical models in the system model, and store the statistical analysis results in the relationship in the database;

[0015] Through the OR mapping co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com