VOCs treatment device and adopted centralized and distributed treatment method thereof

A treatment device and pretreatment technology, which is applied in the direction of combustion method, gas treatment, separation method, etc., can solve the problems of waste of resources, hazardous waste treatment, high investment, etc., and achieve the effect of reducing equipment cost, low investment, and convenient removal and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

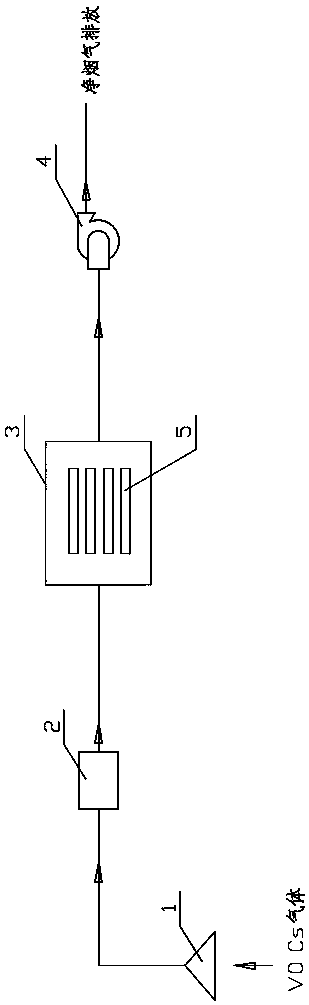

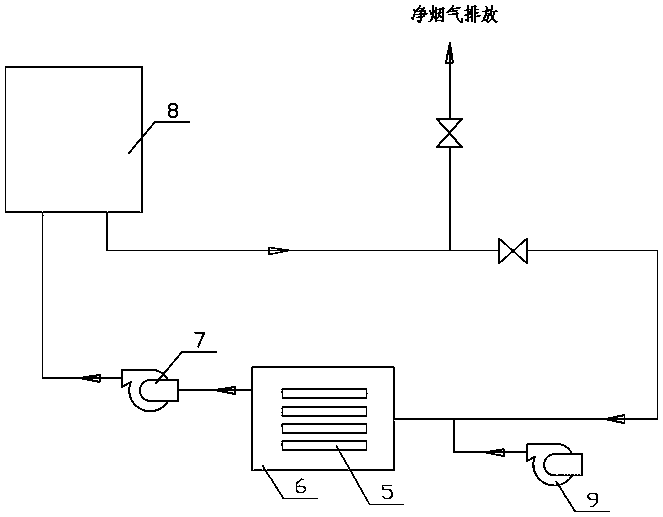

[0044] A certain company has 11 sources of VOCs, which are separated by a certain distance. Among them, the waste gas volume is 20000m 3 / h has 3 places, 15000m 3 / h has 6 locations, 10000m 3 There are 2 locations for / h, and the pollution source is generated within 8 hours of the working day. 11 sets of on-site activated carbon adsorption units and 1 set of adsorbent regeneration units have been established.

[0045] Among them, the adsorption unit includes exhaust gas collection components for VOCs gas collection, pretreatment components, adsorption towers, placement drawers, adsorbents, and exhaust emission equipment. In this embodiment, the exhaust gas collection assembly includes a gas collecting hood, which is connected to the pretreatment component through a pipe, and the pretreatment component is connected to the adsorption tower through the pipe. The adsorbent is arranged in the placing drawer and the adsorbent and the placing drawer constitute the adsorbing component , ...

Embodiment 2

[0053] There are 26 VOCs pollution sources in an industrial park, and the amount of pollution source waste gas ranges from 5000 to 30000m 3 / h, 26 sets of on-site activated carbon adsorption units and 1 set of adsorbent regeneration unit are established on site.

[0054] Among them, the adsorption unit includes exhaust gas collection components for VOCs gas collection, pretreatment components, adsorption towers, placement drawers, adsorbents, and exhaust emission equipment. In this embodiment, the adsorbent is activated carbon, the adsorption tower adopts a fixed bed structure, and the pretreatment component is one or more of a filter device, a de-oil mist device, and a flue gas cooling device.

[0055] The fan provides power for the VOCs gas, so that the VOCs gas is collected through the gas collecting hood and enters the pretreatment component, and then the pretreatment component removes the dust or mist in the VOCs gas collected by the exhaust gas collection component. The gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com